Patents

Literature

34results about How to "Decreased thermal insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-combustible energy-saving heat-preserving board and preparation method thereof

The invention belongs to building materials and relates to a non-combustible energy-saving heat-preserving board and a preparation method thereof. The invention is characterized in that: the non-combustible energy-saving heat-preserving board consists of the following components in percentage by weight: 50 to 80 percent of cement, 0.1 to 1 percent of tackifier, 0.1 to 5 percent of organic foaming agent, 0.1 to 1 percent of inorganic foaming agent, 0.1 to 5 percent of water repellent, 0 to 28 percent of mineral mixture and 0 to 10 percent of vitrified microbubbles; the weight percentage sum of all the components is 100 percent; and the preparation method comprises the steps of adding water into the components, stirring to obtain slurry, performing casting molding and maintaining. A multiple-order gas generation technology for generating gas for two times by using a surfactant foaming agent and an inorganic foaming agent is adopted, so the air hole content can be increased, the shape of air holes generated by foaming of the organic foaming agent is modified, the air hole wall is reinforced, the energy-saving and heat-preserving effect is enhanced, and the non-combustible energy-saving heat-preserving board has low density and high heat-preserving performance.

Owner:WUHAN UNIV OF TECH

Quick-dry phase change waterproof heat insulation coating and preparation method thereof

InactiveCN103113792AImprove insulation effectReduced heat retentionRadiation-absorbing paintsFiberWater requirement

The invention relates to a quick-dry phase change waterproof heat insulation coating and a preparation method thereof. The quick-dry phase change waterproof heat insulation coating is prepared from the following materials by weight percent: 10-50% of styrene acrylate copolymer emulsion, 1-45% of acrylic emulsion, 1-15% of hollow glass microbead composite material, 0.5-10% of perlite composite material, 0.5-8% of kieselguhr composite material, 1-9% of glass fiber, 1-10% of wollastonite fiber, 0.5-5% of titanium dioxide, 5-20% of talcum powder, 0.1-3% of dispersing agent, 0.1-1.0% of antifoaming agent, 0.1-0.5% of antiseptic agent, 0.1-2% of thickening agent and 15-25% of water. The heat insulation property of the coating is superior to that of a traditional heat insulation coating, the complementary function is realized by jointly adding the three composite materials, the workability, plasticity and water requirement of the coating can be adjusted so as to meet the application performance requirement under different temperatures and different occasions, and the production cost can be lowered.

Owner:北京立高科技股份有限公司

High-toughness expanded perlite and phenolic resin composite insulation board and preparation method thereof

InactiveCN105967560AImprove insulation effectImprove compatibility and bondingCeramicwareTetraethyl orthosilicatePerlite

The invention discloses a high-toughness expanded perlite and phenolic resin composite insulation board, which is prepared from the following raw materials (by weight): 0.8-1 part of iminooxadiazindione, 1.2-1.5 parts of nano-silica, 2.8-3.2 parts of zinc methacrylate, 1-1.5 parts of dicyandiamide, 55-57 parts of expanded perlite, 40-42 parts of phenolic resin, 4-4.1 parts of a curing agent HMTA, 2-2.3 parts of steel fiber, 10-11 parts of tetraethyl orthosilicate, a proper amount of 85wt% ammonia water, a proper amount of anhydrous ethanol, 160-180 parts of deionized water, a proper amount of n-hexane, 4-4.5 parts of nano-polytetrafluoroethylene, 0.1-0.2 part of dicumyl peroxide and 3-3.5 parts of 2,2,2-trifluoroethyl acrylate. By using iminooxadiazindione, nano-silica, zinc methacrylate and dicyandiamide, bonding force of expanded perlite and phenolic resin is boosted, toughness and tensile strength of the insulation board are improved, and heat resistance and ageing resistance of the insulation board are also enhanced.

Owner:DANGTU COUNTY KEHUI TRADING

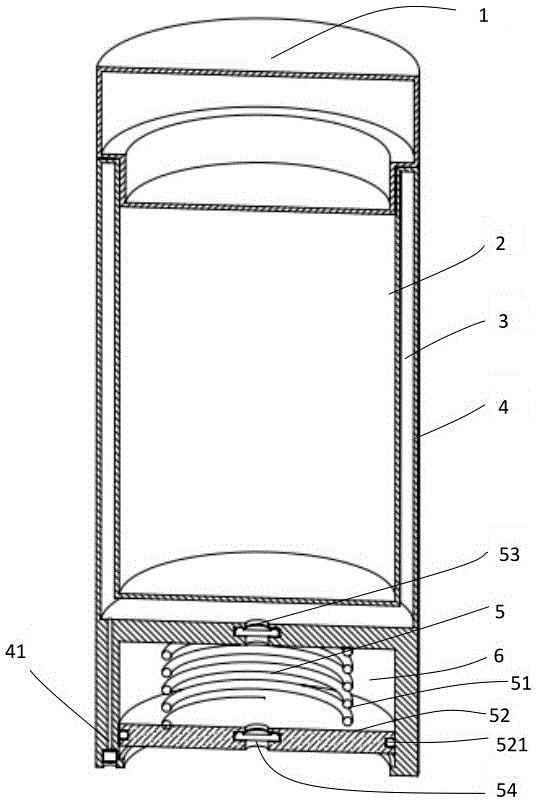

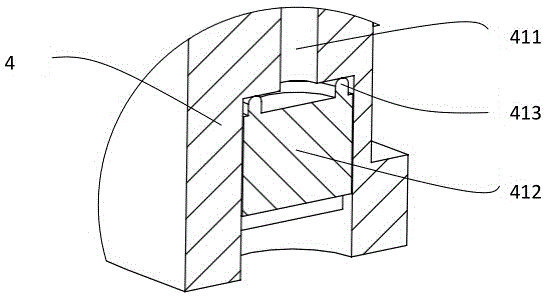

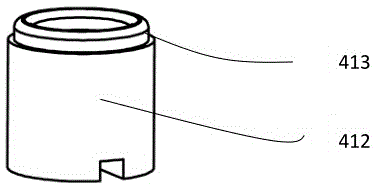

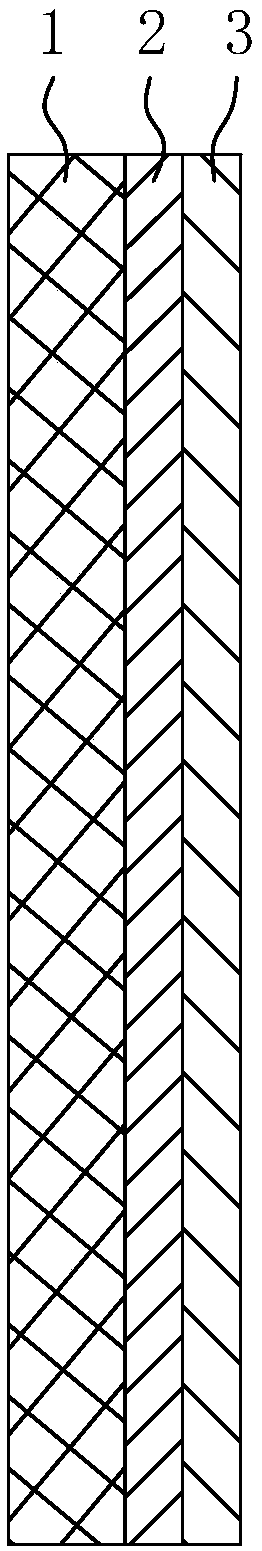

Vacuum cup

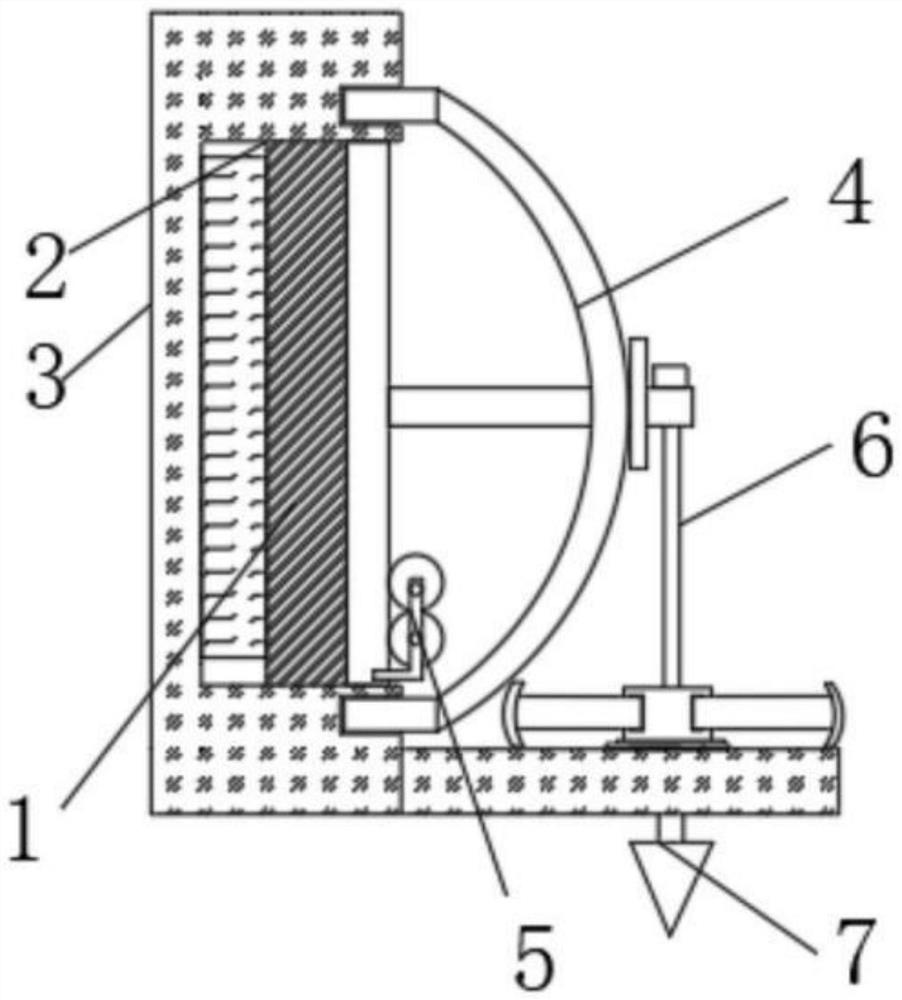

The invention relates to the field of articles for daily use, in particular to a vacuum cup. The vacuum cup comprises a cup lid, a liner, a casing, a pumping device and an inflation device, wherein a vacuum zone exists between the liner and the casing. During use, the pressure value of the vacuum zone can be adjusted by operating the pumping device and the inflation device, so that the thermal insulation performance of the vacuum cup is changed. The vacuum cup can meet different demands for thermal insulation performance in different seasons and is simple in structure, convenient to use and suitable for mass use.

Owner:赵红军

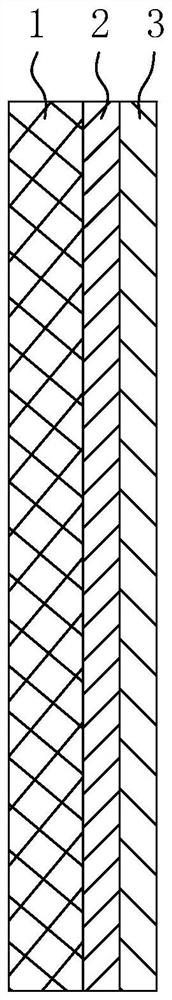

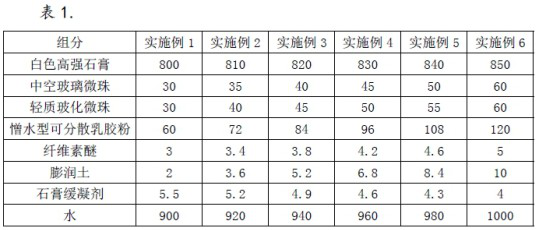

High-strength-gypsum-based sound insulation and thermal insulation machine spraying mortar and composite thermal insulation layer

The invention discloses high-strength-gypsum-based sound insulation and thermal insulation machine spraying mortar, belongs to the technical field of building and ornament materials and preparation, and solves the problem that in the prior art, gypsum-based mortar is not applicable to machine spraying construction. The high-strength-gypsum-based sound insulation and thermal insulation machine spraying mortar is characterized by being prepared from the following components in parts by weight: 800-850 parts of white high-strength gypsum, 30-60 parts of hollow glass beads, 30-60 parts of light glass beads, 60-120 parts of hydrophobic type dispersible latex powder, 3-5 parts of cellulose ether, 2-10 parts of bentonite, 4.0-5.5 parts of gypsum retarder and 900-1,000 parts of water. The gypsum-based mortar has the advantages of high liquidity and high stability, is applied to machine spraying construction, has a good thermal insulation effect after construction, and is high in sound insulation performance and water resistance. The invention correspondingly discloses a preparation method of the high-strength-gypsum-based sound insulation and thermal insulation machine spraying mortar, anda composite thermal insulation layer applying the machine spraying mortar and a construction method of the composite thermal insulation layer.

Owner:苏州高新大乘低碳环保新材发展有限公司

Corncob-modified expanded perlite and phenolic resin composite insulation board and preparation method thereof

The invention discloses a corncob-modified expanded perlite and phenolic resin composite insulation board, which is prepared from the following raw materials (by weight): 1.5-1.9 parts of silicon nanowires, 1.2-1.5 parts of polyaniline nanofiber, 3-4 parts of corncob, a proper amount of 5wt% sodium hydroxide solution, 55-57 parts of expanded perlite, 40-42 parts of phenolic resin, 4-4.1 parts of a curing agent HMTA, 2-2.3 parts of steel fiber, 10-11 parts of tetraethyl orthosilicate, a proper amount of 85wt% ammonia water, a proper amount of anhydrous ethanol, 160-180 parts of deionized water, a proper amount of n-hexane, 4-4.5 parts of nano-polytetrafluoroethylene, 0.1-0.2 part of dicumyl peroxide and 3-3.5 parts of 2,2,2-trifluoroethyl acrylate. By using polyaniline nanofiber for modification of corncob and then by puffing, corncob fiber has good toughness and good heat insulating property. Thus, toughness and heat insulating property of the insulation board are enhanced. By using silicon nanowires, wear resistance of the insulation board is boosted.

Owner:DANGTU COUNTY KEHUI TRADING

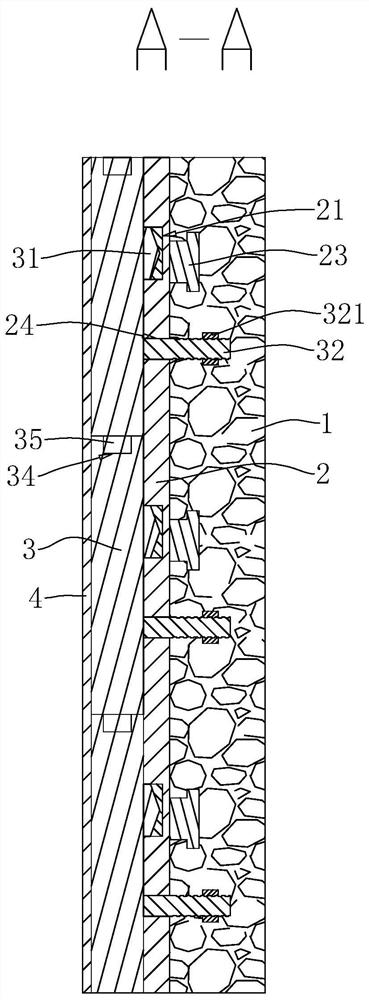

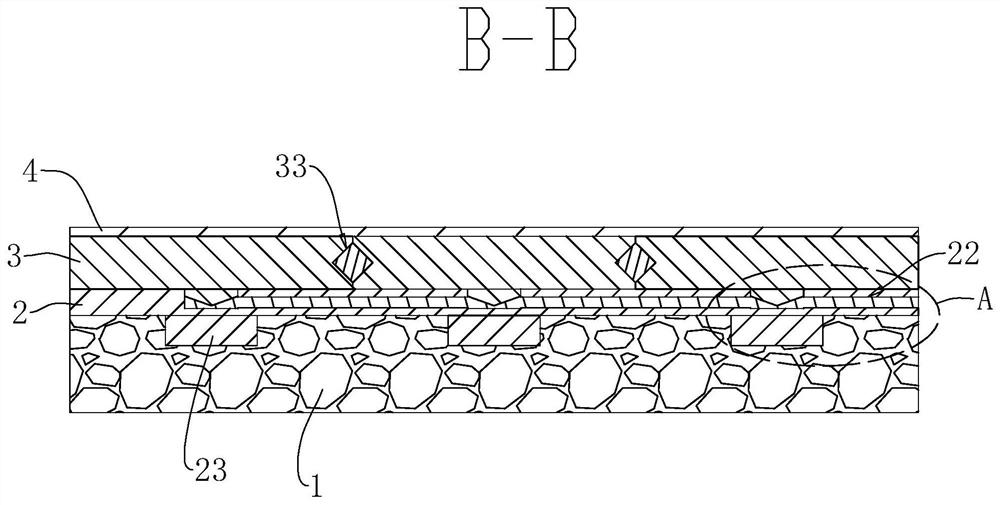

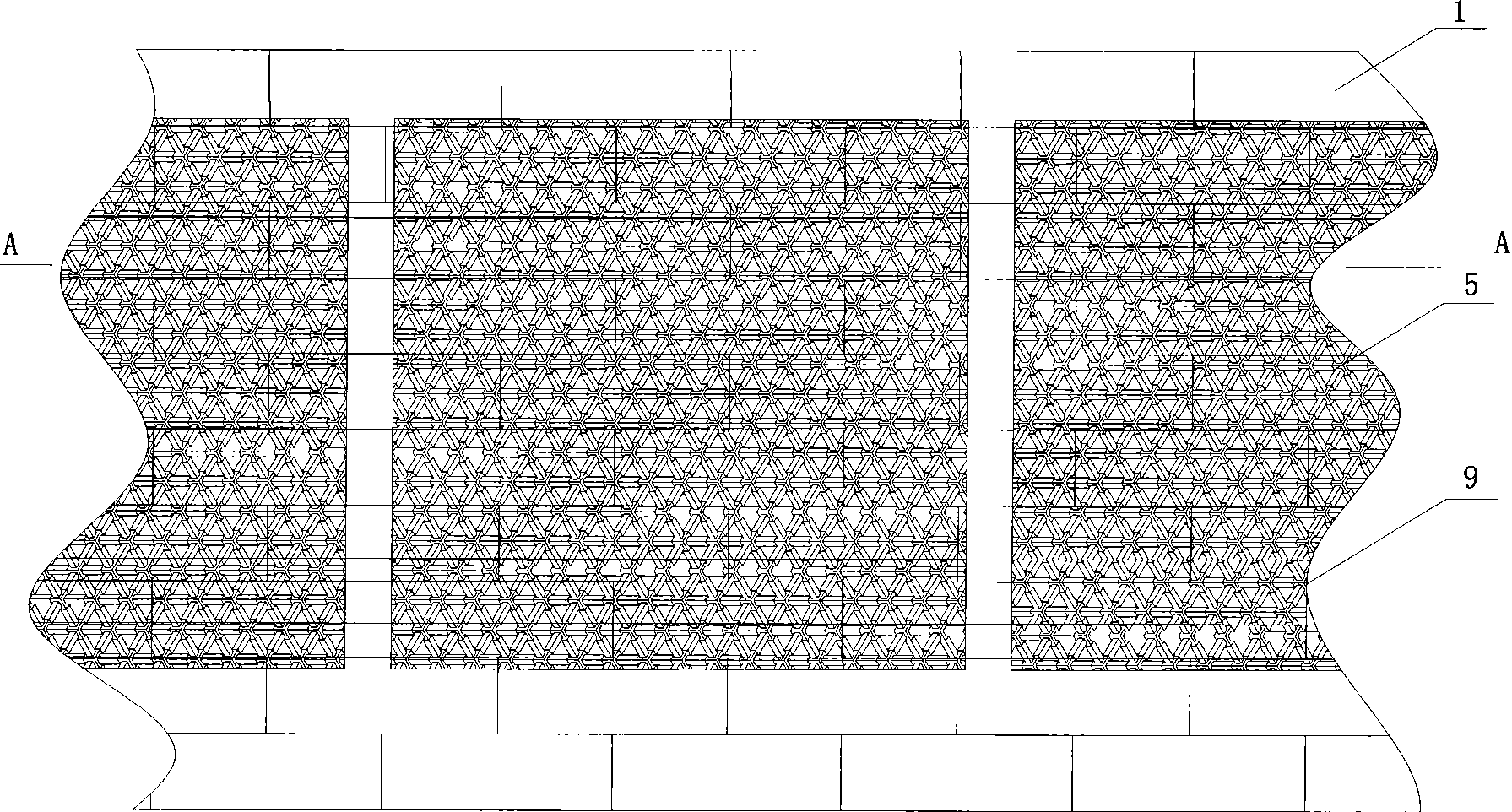

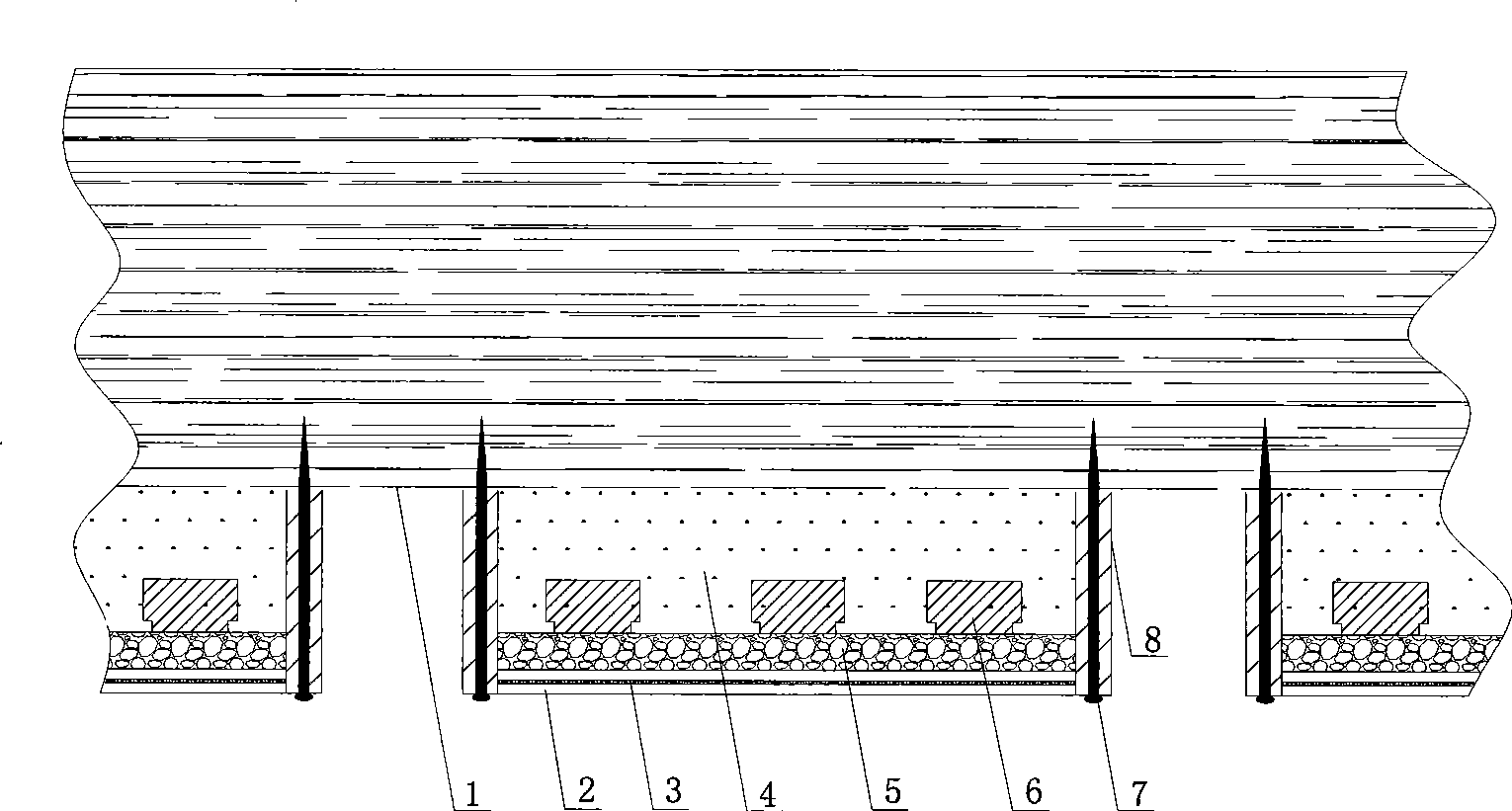

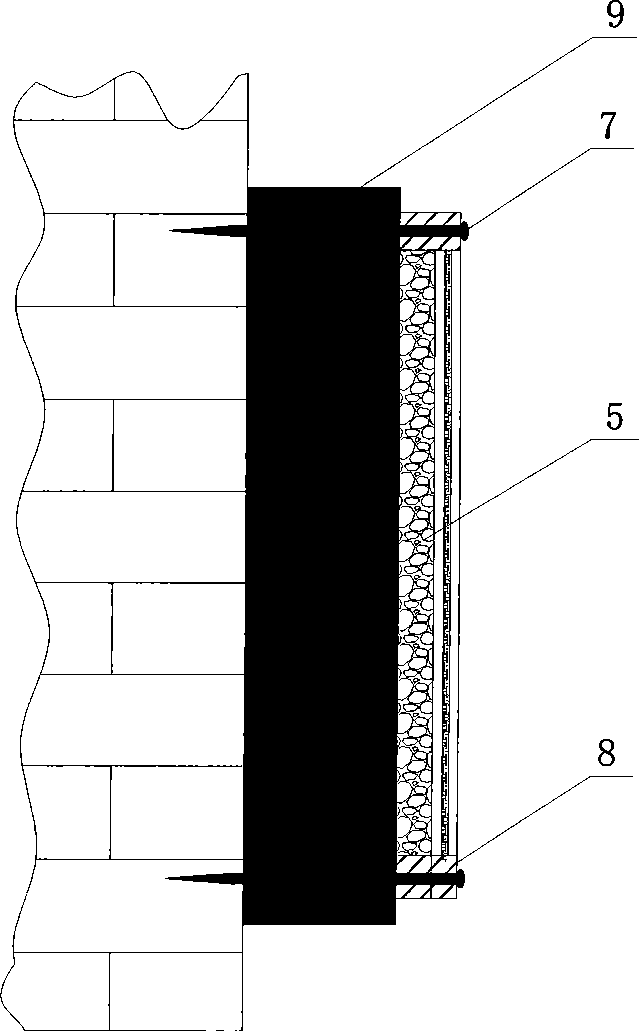

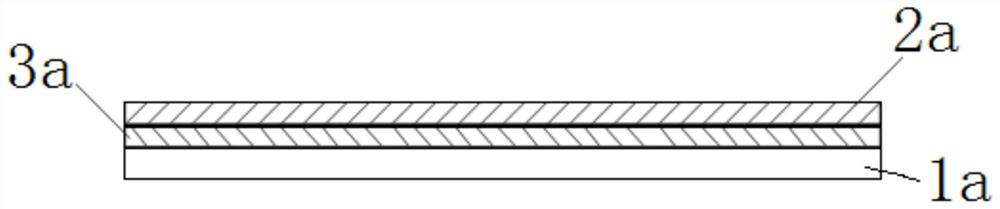

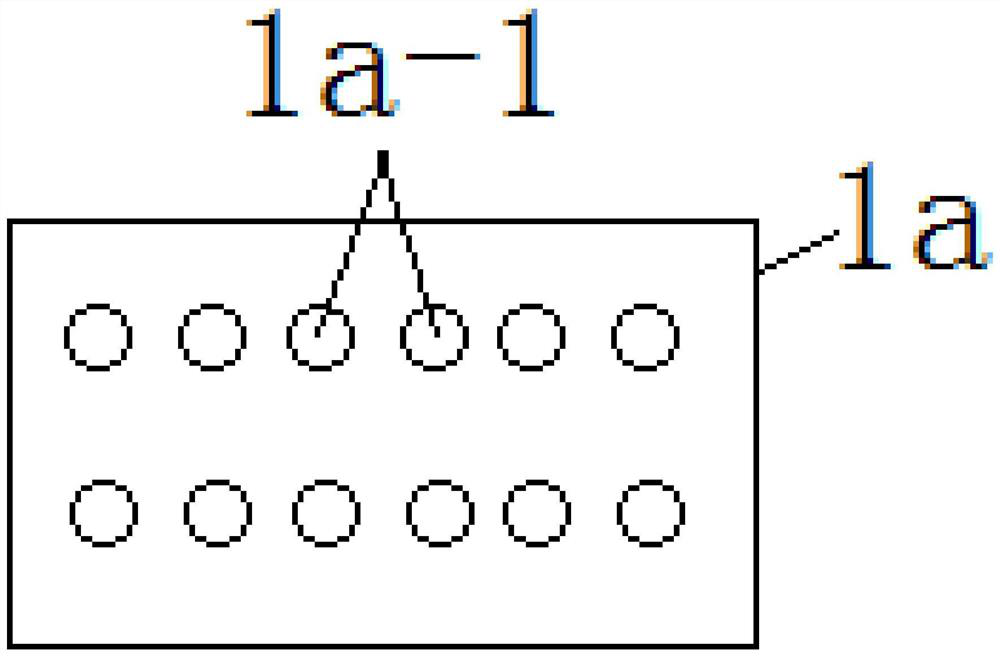

Thin heat insulation composite heat insulation board and cast-in-place concrete composite wall and construction method

PendingCN112982746AGuaranteed insulation performance and service lifeDecreased thermal insulationWallsHeat proofingComposite materialEngineering

Owner:南京垄基节能科技有限公司

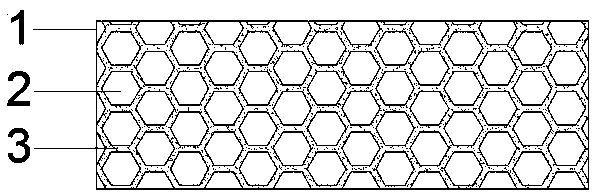

Inorganic composite polyphenyl A level heat-preserving plate

PendingCN110409642AHigh strengthImprove fire performanceClimate change adaptationInsulation improvementHoneycombPolystyrene particle

The invention discloses an inorganic composite polyphenyl A level heat-preserving plate. A heat preserving plate body is included, and comprises a common polystyrene plate blank material and a cement-based inorganic fireproof material; the cement-based inorganic fireproof material makes a cement-based inorganic fireproof pulp-shape material uniformly permeate to the position around polystyrene particles and wrap the position around the polystyrene particles, and a honeycomb-shaped supporting framework structure is formed; and the homogenous inorganic composite polyphenyl A level heat-preserving plate is formed due to moisture preserving and maintaining curing in one stage.

Owner:山东刚磊建材科技有限公司

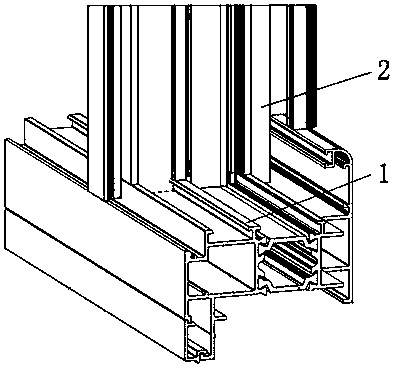

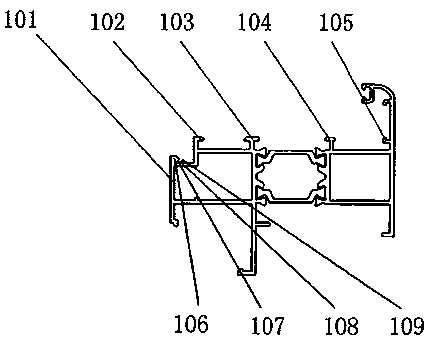

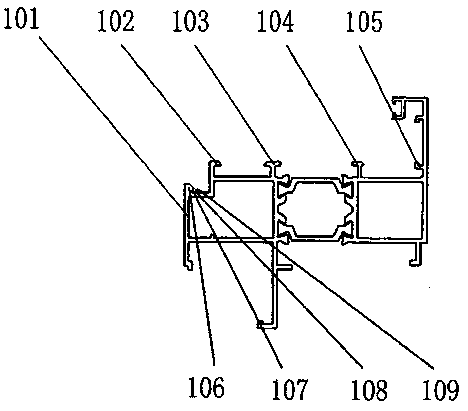

Combined type casement window system

PendingCN109322588APlay a decorative roleIncrease deflectionWindow/door framesRain/draught deflectorsWater blockUltimate tensile strength

The invention relates to the technical field of doors and windows, in particular to a combined type casement window system. The combined type casement window system comprises a secondary frame, a window frame, a middle stile, a window sash and a screen sash; the window frame is fixedly connected with a wall body through the secondary frame, the secondary frame can effectively block the transmission of a hot and cold bridge, and the secondary frame is connected with the window frame through connecting plates and screws; the window frame water blocking wind proof plates are lapped against firmlyor connected with secondary frame water blocking wind proof plates through the screws, and are waterproof and windproof effectively; the internal and external casement window ash is formed by using standard hinges through the middle stile or the window frame; and attaching edges are arranged on the window frame and the middle stile, the window frame is connected with the middle stile through theattaching edges in a buckled mode, the connection strength is effectively ensured, the wind-resistant performance of the window frame is greatly improved. The cross section of the window frame is in an L shape, the cross section of the middle stile is in a T shape so as to be attached with the window frame conveniently, meanwhile, the T shaped cross section of the middle stile can further improvedeflection of profiles, and further improves the wind-resistant performance of the whole window. A gathered composite structure forms the functional integrated combined type casement window system, the applicability is greatly improved.

Owner:兰州圣亚斯科技研发有限公司

Expanded perlite and phenolic resin composite insulation board with good heat resistance and preparation method thereof

The invention discloses an expanded perlite and phenolic resin composite insulation board with good heat resistance. The composite insulation board is prepared from the following raw materials (by weight): 1.3-1.6 parts of dilauryl thiodipropionate, 2.6-2.9 parts of ferroceneboronic acid, 1.2-1.4 parts of beta-glucan, 3-3.5 parts of active carbon, 55-57 parts of expanded perlite, 4-4.1 parts of a curing agent HMTA, 2-2.3 parts of steel fiber, 10-11 parts of tetraethyl orthosilicate, a proper amount of 85wt% ammonia water, a proper amount of anhydrous ethanol, 160-180 parts of deionized water, a proper amount of n-hexane, 4-4.5 parts of nano-polytetrafluoroethylene, 0.1-0.2 part of dicumyl peroxide and 3-3.5 parts of 2,2,2-trifluoroethyl acrylate. By using dilauryl thiodipropionate and beta-glucan for modification of active carbon, heat resistance and heat insulating property of the insulation board can be enhanced. By using ferroceneboronic acid, heat resistance of the insulation board is boosted, and reduction of heat insulating property due to water adsorption is prevented.

Owner:DANGTU COUNTY KEHUI TRADING

Anti-compression expanded perlite and phenolic resin composite insulation board and preparation method thereof

The invention discloses an anti-compression expanded perlite and phenolic resin composite insulation board, which is prepared from the following raw materials (by weight): 1.5-1.9 parts of floating beads, 1.2-1.5 parts of nonionic boric acid ester, 0.9-1.2 parts of tetramethylammonium fluoride, 3-4 parts of light microporous mullite powder, 55-57 parts of expanded perlite, 40-42 parts of phenolic resin, 4-4.1 parts of a curing agent HMTA, 2-2.3 parts of steel fiber, 10-11 parts of tetraethyl orthosilicate, a proper amount of 85wt% ammonia water, a proper amount of anhydrous ethanol, 160-180 parts of deionized water, a proper amount of n-hexane, 4-4.5 parts of nano-polytetrafluoroethylene, 0.1-0.2 part of dicumyl peroxide and 3-3.5 parts of 2,2,2-trifluoroethyl acrylate. By using nonionic boric acid ester and tetramethylammonium fluoride for modification of floating beads and light microporous mullite powder, heat insulating property and water resistance of the floating beads and light microporous mullite powder are raised, and compression resistance and heat insulating property of the insulation board can be boosted.

Owner:DANGTU COUNTY KEHUI TRADING

Insulation wall and manufacturing process thereof

InactiveCN101545293AReduce project costImprove crack resistanceConstruction materialWallsInsulation layerThermal insulation

The invention discloses an insulation wall and a manufacturing process thereof. The insulation wall comprises a wall body, an insulation layer, a protective layer and a finishing coat, wherein the insulating layer comprises insulation boards which are composite boards made from rigid polyurethane foam generated by on-site injection and foaming of rigid polyurethane, and XPS extruded sheets; the protective layer comprises guard plates which are composite boards formed by taking glazed hollow beads as aggregate; and the wall body and the guard plates are fixedly connected through the rigid polyurethane foam in the insulation boards. The manufacturing process comprises that: non-dismounting fixing plates are manufactured, which comprise the guard plates and the XPS extruded sheets, and the guard plates are made by taking the glazed hollow beads as the aggregate and materials such as cement, mortar and the like as additives; b, the non-dismounting fixing plates are fixed on the external surface of the wall body, and the bottom surfaces and the side surfaces of the fixing plates are sealed; c, the rigid polyurethane is filled in a rigid polyurethane injection device, and is injected along vertical seams of the XPS extruded sheets; and d, after the rigid polyurethane foam is cured, sealing devices are detached. The insulation wall has the advantages of good thermal insulation property, fireproofing, freezeproofing and simple manufacture.

Owner:程争鸣

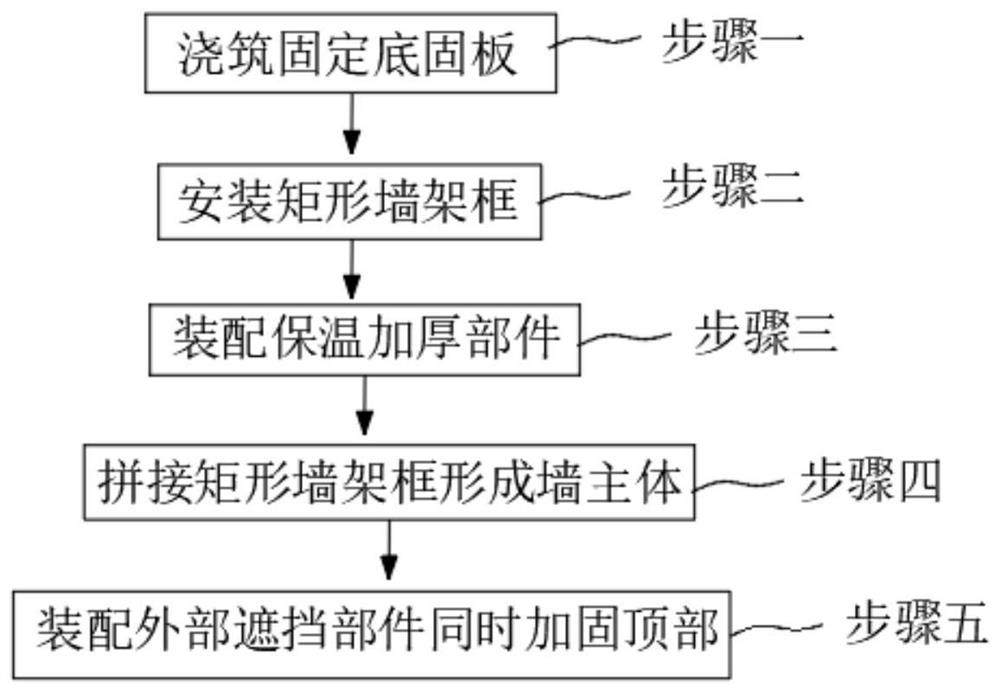

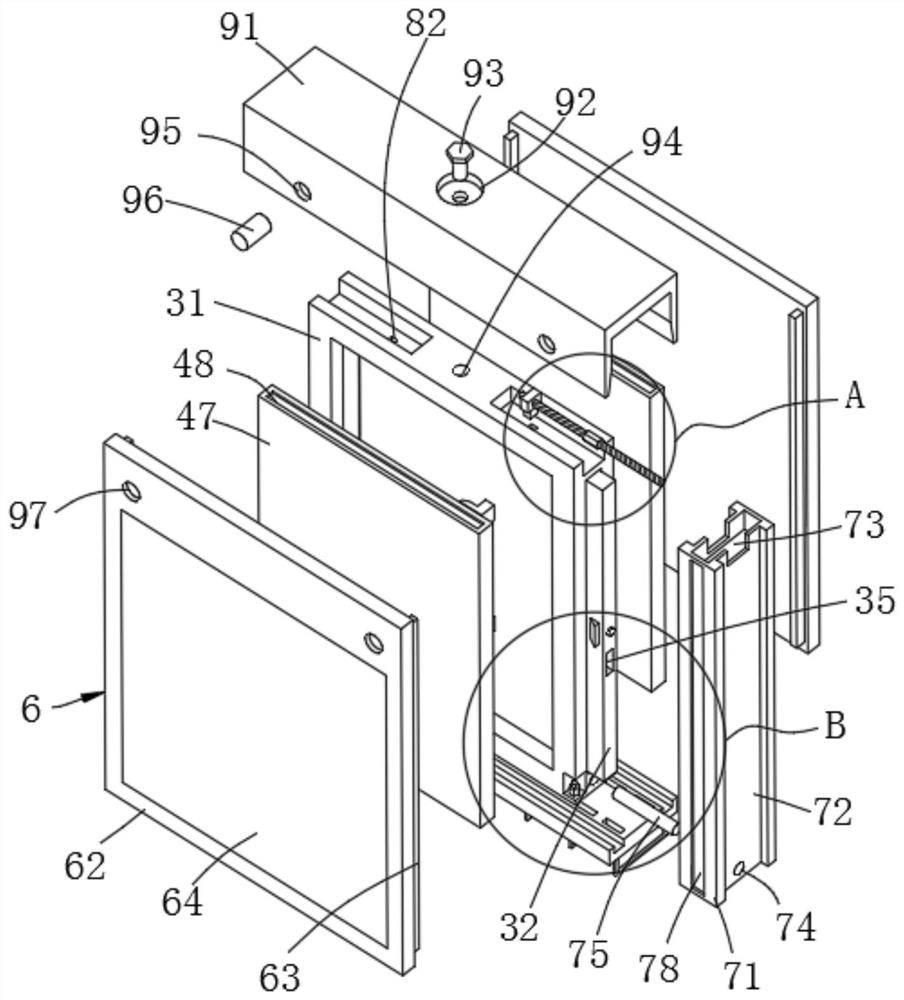

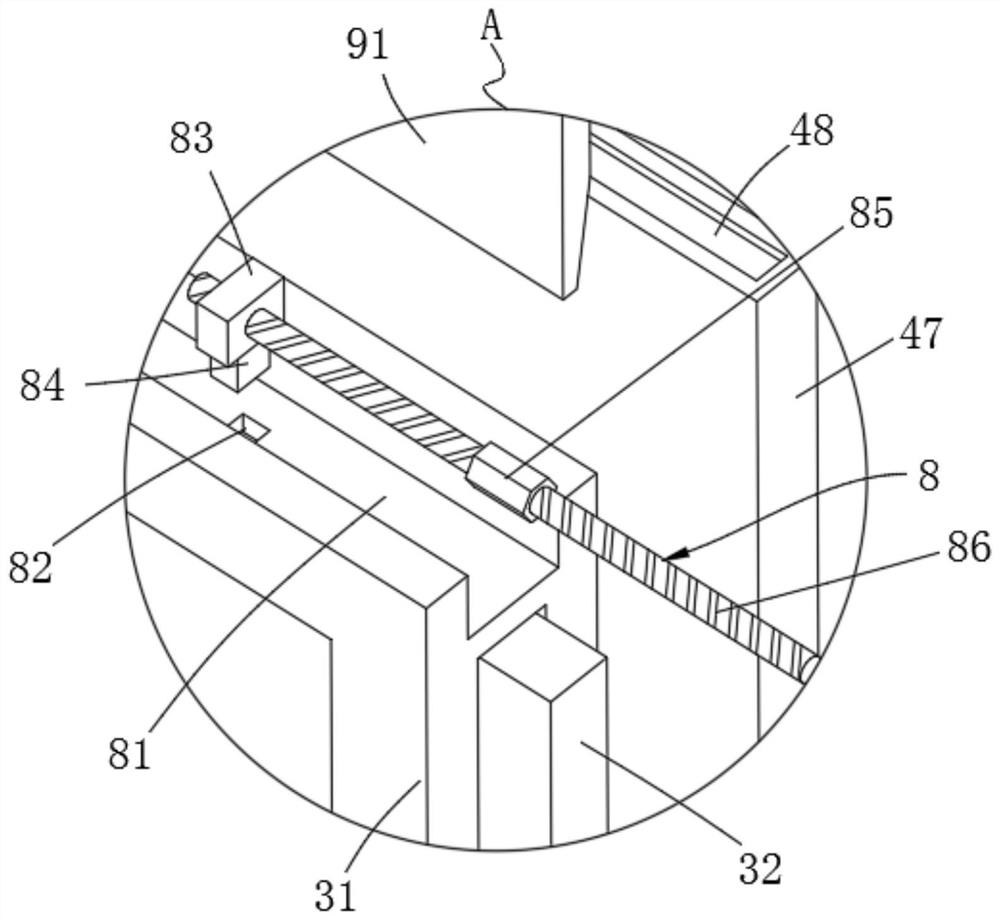

Fabricated building external wall thermal insulation construction process

InactiveCN114809362AImprove insulation effectAchieve fixationWallsHeat proofingArchitectural engineeringHeat conservation

The invention provides an assembly type building outer wall heat preservation construction technology, and relates to the technical field of assembly type building outer walls, the assembly type building outer wall heat preservation construction technology comprises the following technological steps: 1, pouring and fixing a bottom fixing plate, fixing a U-shaped pouring rib at the bottom of the bottom fixing plate in the assembly type building outer wall, and then pouring the U-shaped pouring rib at a construction position through concrete, the bottom fixing plate is kept in a horizontal state during pouring; secondly, a rectangular wall shelf frame is installed, and the rectangular wall shelf frame of the wall shelf heat preservation unit in the fabricated building outer wall is fixed to the upper side of a bottom fixing plate through a wallboard bottom fixing assembly at the bottom of the fabricated building outer wall; step 3, assembling a heat preservation thickening part; the building outer wall is built in an assembling mode, meanwhile, the heat preservation performance of the wall can be guaranteed, gaps generated by assembling can be blocked, heat preservation performance reduction caused by gap air leakage is avoided, external impact can be buffered, and the situation that the overall firmness of the building outer wall is affected due to the fact that collision received by the outer side is conducted to the interior is avoided.

Owner:陈杰

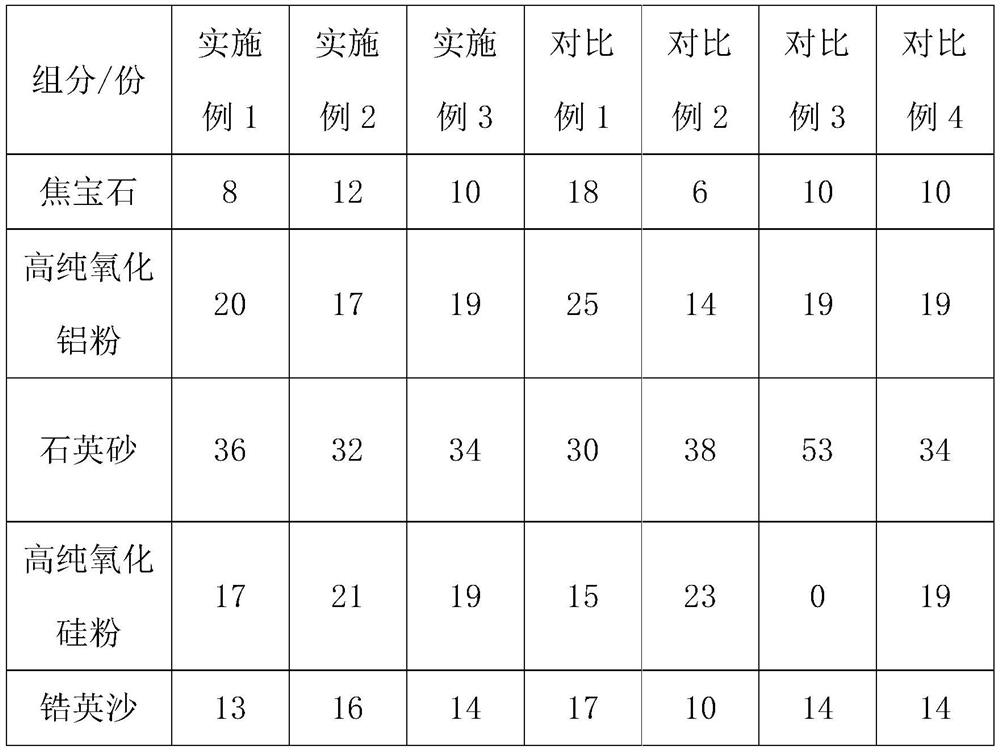

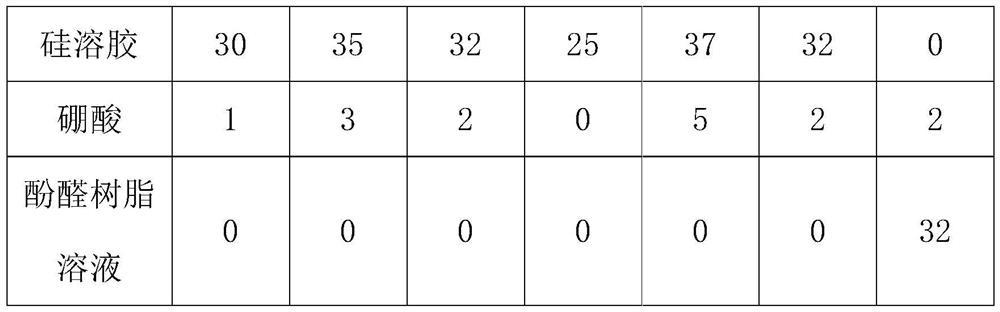

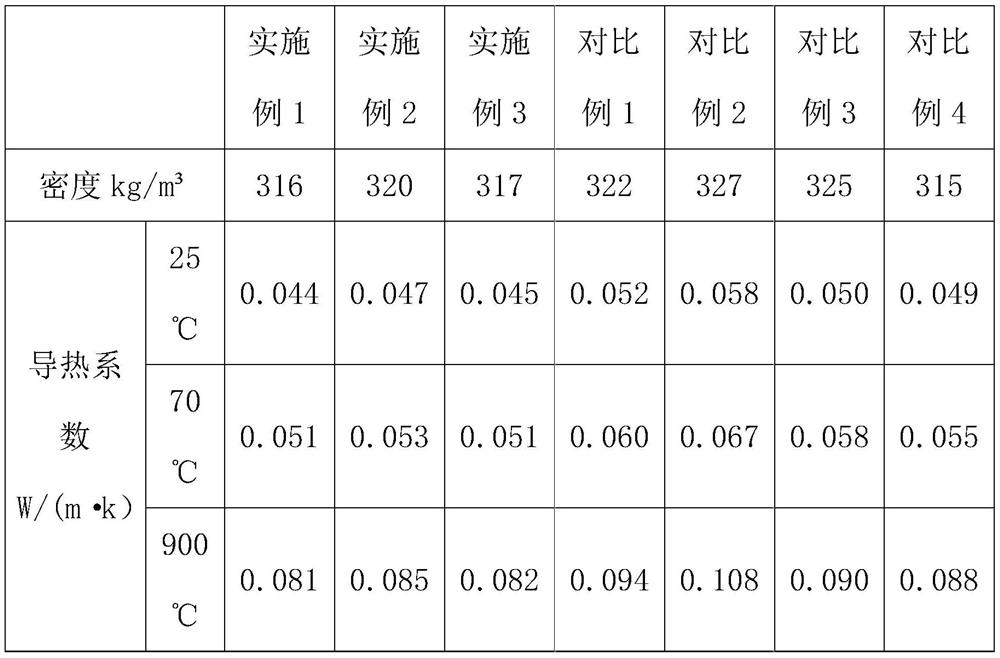

Inorganic silicon crystal plate and manufacturing method thereof

ActiveCN114195432AImprove thermal stabilityGood high temperature resistanceInorganic material artificial filamentsOxideSilicon oxide

The invention provides an inorganic silicon crystal plate and a manufacturing method thereof. The inorganic silicon crystal plate comprises the following raw materials in parts by weight: 7-12 parts of flint clay, 16-22 parts of high-purity alumina powder, 32-37 parts of quartz sand, 18-22 parts of high-purity silicon oxide powder, 11-16 parts of zircon sand, 28-34 parts of silica sol and 1-3 parts of boric acid. The inorganic silicon crystal plate is prepared by heating, melting and blowing raw materials including flint clay, high-purity aluminum oxide powder, quartz sand and zircon sand into fibers, spraying and attaching a silica sol composite solution dispersed with the high-purity silicon oxide powder to the surfaces of the fibers, performing mold pressing to form a base plate, and finally performing high-temperature sintering. The obtained inorganic silicon crystal plate is resistant to corrosion, low in deformation, light in weight, high in strength and capable of insulating heat and preserving heat, is an excellent substitute of an existing fireproof heat preservation plate, can be used at the highest temperature of 1500 DEG C, and can meet the application requirements of smoke prevention and exhaust air pipes, building fireproof plates, fireproof door inner materials and the like as a light, high-strength, high-temperature-resistant and fireproof plate.

Owner:江苏华风新材料科技有限公司

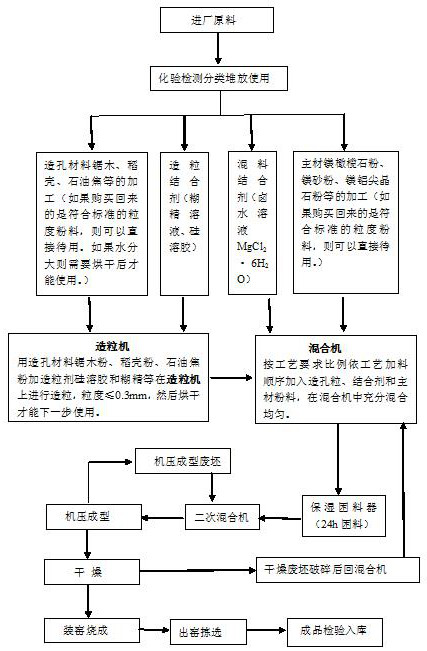

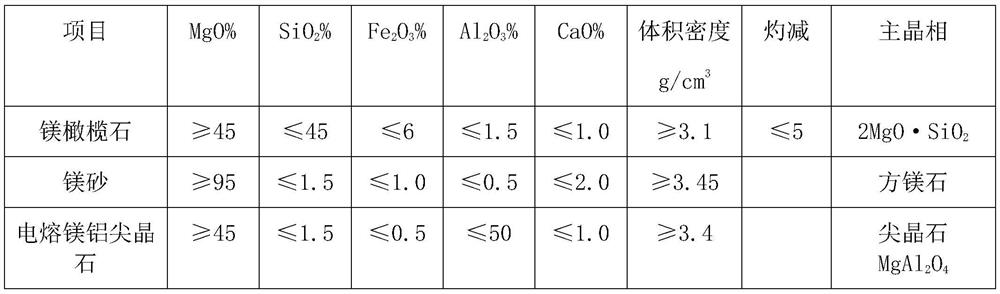

Anti-seepage high-strength forsterite light heat-insulating brick and preparation method thereof

The invention discloses an anti-seepage high-strength forsterite light heat-insulating brick, which comprises the raw materials of forsterite powder, magnesia powder, fused magnesia-alumina spinel powder and a pore-forming material, wherein the particle size d of the magnesia powder and the forsterite powder is less than or equal to 0.044 mm, the particle size d of the fused magnesia-alumina spinel powder is less than or equal to 0.088 mm, the particle size d of the pore-forming material is less than or equal to 0.3 mm, and the mass ratio of the forsterite powder to the magnesia powder to thefused magnesia-alumina spinel powder to the pore-forming material is (30-42): (8-15): (5-10): (40-60). The preparation method comprises the steps of S1, purchasing raw materials and processing the rawmaterials to required granularity, and adding a pore-forming material and a binding agent into a granulator for granulation; S4, selecting magnesia powder, forsterite powder, fused magnesia-alumina spinel powder and the granular pore-forming material, and putting the materials into a mixing machine for full mixing; S5, ageing the materials, and then putting the aged materials into the mixing machine for secondary mixing; and S6, conducting mechanical pressing forming, and then conducting kiln loading and firing.

Owner:河南鑫诚耐火材料股份有限公司

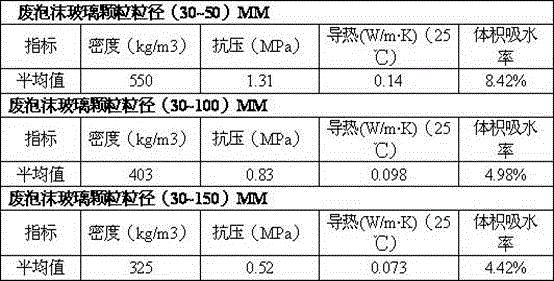

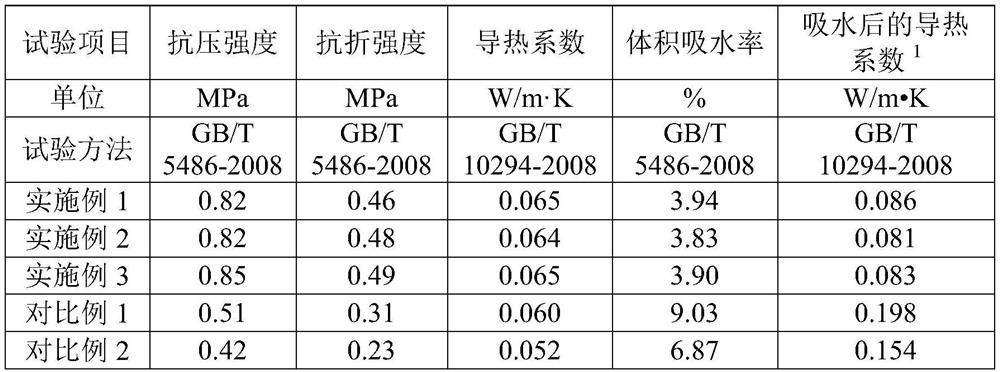

A method of making insulation board by using foam glass waste

ActiveCN104045278BSolving the Recycling DilemmaDecreased thermal insulationSolid waste managementWater-setting substance layered productSocial benefitsCellulose

The invention discloses a method for manufacturing a heat-preservation plate by using a foam glass waste material. The method is characterized by comprising the following steps: uniformly stirring foam glass fragments, foam glass powder, cellulose, rubber powder, cement and lime by using water, pouring to obtain a rectangular body by using a mold, naturally drying, and then slitting into a platy reclaimed material finished product, wherein the weight percentage of the foam glass fragments is 60-65%; the block diameter of each foam glass fragment is 30-150mm; the weight percentage of the foam glass powder is 15-17%; the weight percentage of cellulose is 0.2-0.3%; the weight ratio of the rubber powder is 0.1-0.15%; the weight percentage of the cement is 14-16%; the weight percentage of lime is 4-5%; meanwhile, a reclaimed material and a non-reclaimed material are compounded, so that each performance index can be further improved, and more application requirements can be met. More importantly, the method disclosed by the invention is used for creatively solving the difficulties of recycling foam glass fragment wastes, and has economic and social benefits.

Owner:JIAXING AOTAI NEW BUILDING MATERIALS CO LTD

Inorganic lightweight aggregate insulation board and preparation method thereof

The invention relates to the field of building thermal insulation materials, and discloses an inorganic lightweight aggregate insulation board and a preparation method thereof. The insulation board is prepared from the following raw materials in parts by weight: 390 to 410 parts of modified expanded perlite, 90 to 110 parts of Portland cement, 25 to 28 parts of waterproof glue, 1.1 to 1.5 parts of curing powder, 0.3 to 0.5 part of polypropylene fibers and 1 to 2 parts of water, wherein the surface of the modified expanded perlite is coated with a hydrophobic layer, and the hydrophobic layer is externally grafted with alkoxy-terminated silane dendrimers. According to the insulation board, the surface of the expanded perlite is fully covered with the hydrophobic layer, water can be prevented from permeating into internal pores of the expanded perlite, so the thermal insulation performance of the insulation board in a humid environment is prevented from being reduced; and the expanded perlite and the cement form a large number of covalent bonds through alkoxy-terminated silane dendrimers, so the strength of the insulation board is high.

Owner:浙江瑞联节能材料有限公司

Sand-wood composite material and preparation method thereof

InactiveCN111978014AGood dispersionImprove bonding densityKitchen cabinetsFlooringGlass fiberPolystyrene

The invention belongs to the technical field of composite materials, and particularly discloses a sand-wood composite material and a preparation method thereof. Phenolic resin, polystyrene, attapulgite, a coupling agent, titanium dioxide, silica sand and the like are matched in a specific proportion for use for the first time, the coupling agent can improve the dispersity of titanium dioxide and silica sand in a system, titanium dioxide and silica sand are prevented from being gathered into a cluster in the system, and the heat preservation performance of the product is improved; meanwhile, the coupling agent can firmly couple titanium dioxide and silica sand into a base material formed by phenolic resin, polystyrene and the like, so that the product is stable in structure and has lastingheat preservation performance; titanium dioxide and the coupling agent are coupled and uniformly dispersed in the whole system, so that the product has waterproof performance, the water absorption phenomenon of the product after long-time use is avoided, the water content of the product is reduced, and the heat preservation durability of the product is improved; and glass fibers can maintain the pore structure of the product, the bonding compactness among all raw materials is improved, and the heat preservation performance of the product is improved.

Owner:BEIJING RECHSAND SCI & TECH GRP +1

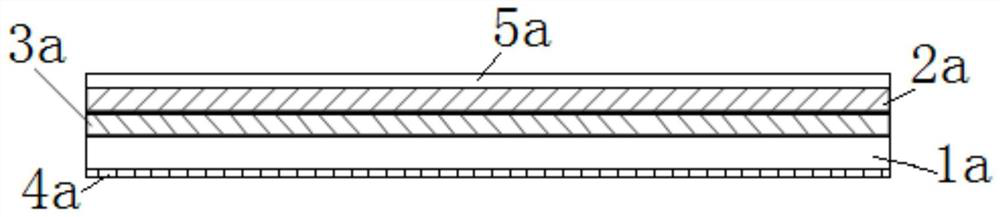

Heat preservation material for covering and overwintering wine grapes in low-temperature area and making method of heat preservation material

InactiveCN105594525AImprove insulation effectNo frost damageSynthetic resin layered productsCultivating equipmentsPolyesterVitis vinifera

The invention discloses a heat preservation material for covering and overwintering wine grapes in a low-temperature area and a making method of the heat preservation material. The heat preservation material is formed by connecting four layers of materials, namely polyester filament cloth arranged on the first layer, a non-drop greenhouse film arranged on the second layer, a needle punched felt arranged on the third layer and a foaming material arranged on the fourth layer. The heat preservation effect is achieved through the design of the four layers and the synergistic effect among the materials, moisture is effectively prevented from entering, and heat preservation performance is long in lasting time; mechanized operation of a volume curtain machine can be achieved through rivet clasp design and thread gluing design. According to the heat preservation material, in the production process, a rotary cultivator can be utilized to press edges, and work efficiency is greatly improved.

Owner:GANSU AGRI UNIV

Cotton pulp-reinforced expanded perlite and phenolic resin composite insulation board and preparation method thereof

The invention discloses a cotton pulp-reinforced expanded perlite and phenolic resin composite insulation board, which is prepared from the following raw materials (by weight): 3-3.5 parts of cotton pulp, 1-1.3 parts of poly(dimethyl cyclosiloxane), 2-2.5 parts of n-butyl borate, 1.3-1.6 parts of octyltin mercaptide, 55-57 parts of expanded perlite, 40-42 parts of phenolic resin, 4-4.1 parts of a curing agent HMTA, 2-2.3 parts of steel fiber, 10-11 parts of tetraethyl orthosilicate, a proper amount of 85wt% of ammonia water, a proper amount of anhydrous ethanol, 160-180 parts of deionized water, a proper amount of n-hexane, 4-4.5 parts of nano-polytetrafluoroethylene, 0.1-0.2 part of dicumyl peroxide and 3-3.5 parts of 2,2,2-trifluoroethyl acrylate. By using poly(dimethyl cyclosiloxane) and n-butyl borate for modification of cotton pulp, strength, water resistance and heat resistance of the insulation board can be boosted. By the use of octyltin mercaptide, heat resistance and ageing resistance of the insulation board are improved.

Owner:DANGTU COUNTY KEHUI TRADING

Moisture-proof sound-proofing expanded perlite and phenolic resin composite insulation board and preparation method thereof

The invention discloses a moisture-proof and sound-insulating expanded perlite phenolic resin composite insulation board, which is made of the following raw materials in parts by weight: diethyl malonate 0.5-0.6, ethyl acetoacetate 0.4-0.5, polyisocyanate 2-2.4, 3, 5-lutidine 1.2-1.5, expanded perlite 55-57, phenolic resin 40-42, curing agent HMTA4-4.1, steel fiber 2-2.3, tetraethyl orthosilicate 10-11, 85wt% ammonia in proper amount , Appropriate amount of absolute ethanol, deionized water 160-180, appropriate amount of n-hexane, nano-polytetrafluoroethylene 4-4.5, cumene peroxide 0.1-0.2, trifluoroethyl acrylate 3-3.5. The invention modifies the expanded perlite by using diethyl malonate, ethyl acetoacetate, 3,5-lutidine and polyisocyanate, and forms small holes inside the perlite, which improves the moisture-proof and sound-proof insulation of the insulation board performance.

Owner:DANGTU COUNTY KEHUI TRADING

Foamed concrete heat insulation board

ActiveCN112627370ADecreased thermal insulationImprove protectionLivestock managementCuttersStructural engineeringMechanical engineering

The invention discloses a foamed concrete heat insulation board. The foamed concrete heat insulation board comprises two board bodies, wherein a clamping mechanism, a fixing mechanism and a protection mechanism are sequentially arranged outside each board body; and each fixing mechanism is composed of a concave frame, a rectangular plate and a long plate, wherein the rectangular plate is fixedly installed at the position, close to the middle, of the inner surface of the concave frame, and transverse grooves are formed in the front and back positions, close to the upper end, of the outer surface of the right side of the concave frame. The foamed concrete heat insulation board can serve as a shell of a wall to protect and install a heat insulation board body, and a shed body can be temporarily built conveniently; in addition, rainwater can conveniently slide down, the situation that the board bodies are wetted by the rainwater can be reduced, the waterproofness of the board bodies is improved, the probability that reptiles gnaw and damage equipment is reduced, the protection effect of the board bodies is effectively improved, the probability that boston ivy climbs on the wall is reduced, and the risk that the boston ivy hurts the wall is reduced; and sunlight can conveniently irradiate the wall, and therefore the heat insulation effect is better achieved.

Owner:联海装配式建材有限公司

Sound-proofing heat-resistant expanded perlite and phenolic resin composite insulation board and preparation method thereof

The invention discloses a sound insulation and heat-resistant expanded perlite phenolic resin composite insulation board, which is made of the following raw materials in parts by weight: polyaluminum chloride 1.3-1.6, silicon boron molecular sieve 2.6-2.9, concentrated ammonia water 5-6, attapulgite rod Soil 3-3.5, expanded perlite 55-57, phenolic resin 40-42, curing agent HMTA4-4.1, steel fiber 2-2.3, ethyl orthosilicate 10-11, appropriate amount of 85wt% ammonia water, appropriate amount of anhydrous ethanol, remove Ionized water 160-180, proper amount of n-hexane, nano-polytetrafluoroethylene 4-4.5, cumene peroxide 0.1-0.2, trifluoroethyl acrylate 3-3.5. By using polyaluminum chloride and concentrated ammonia water to modify attapulgite, the invention can improve the brittleness and water resistance of the thermal insulation material, and improve the sound absorption effect; by using the silicon boron molecular sieve, the heat resistance and sound insulation of the thermal insulation board are improved Effect.

Owner:DANGTU COUNTY KEHUI TRADING

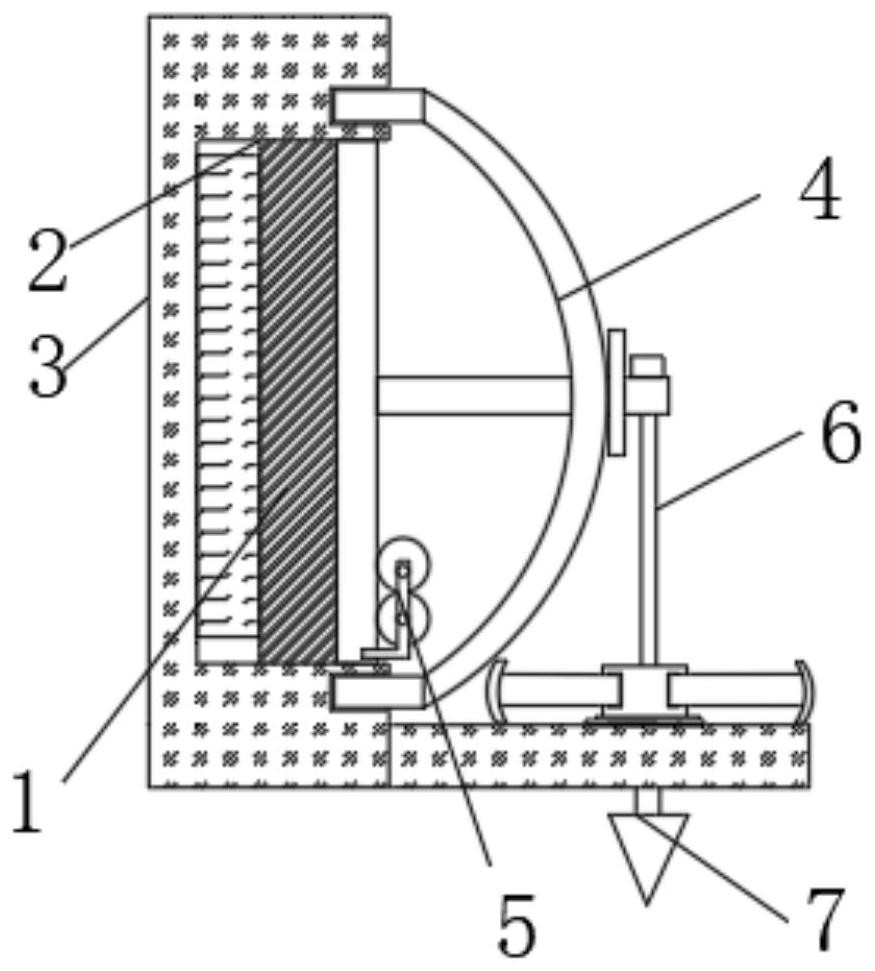

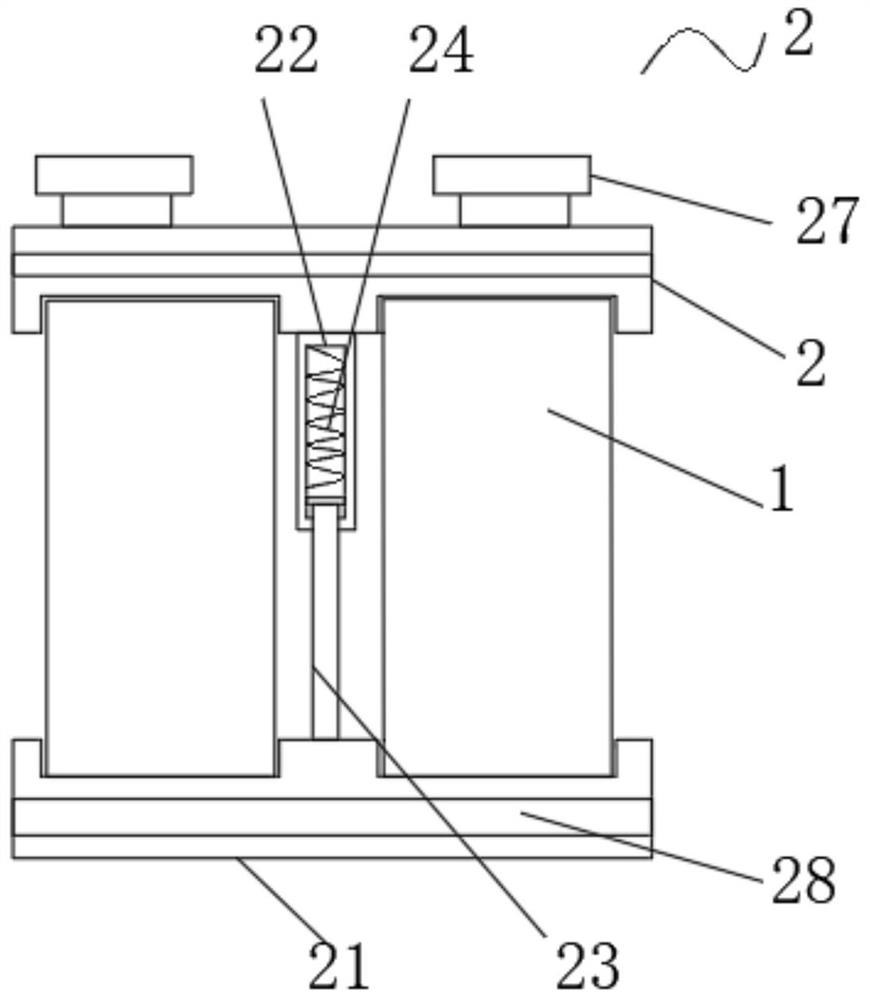

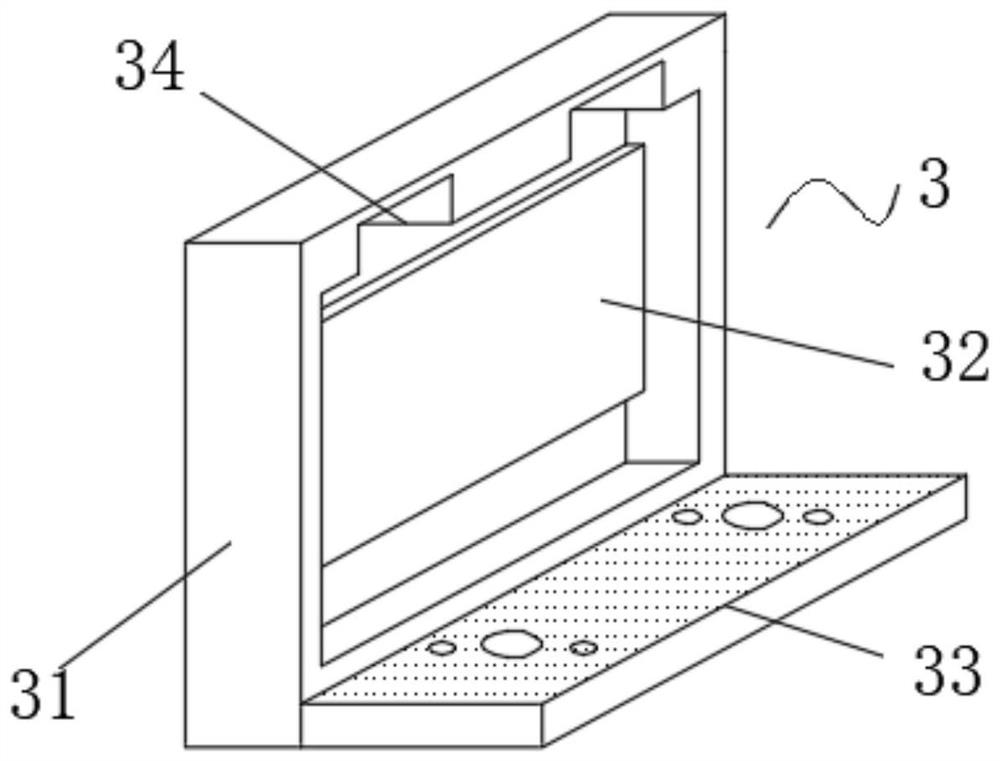

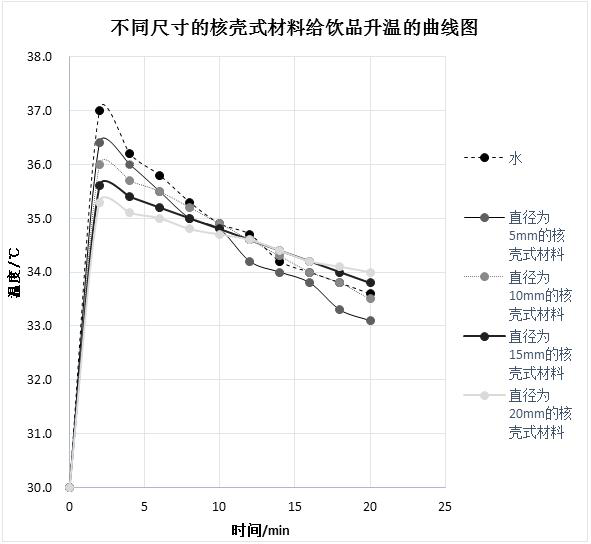

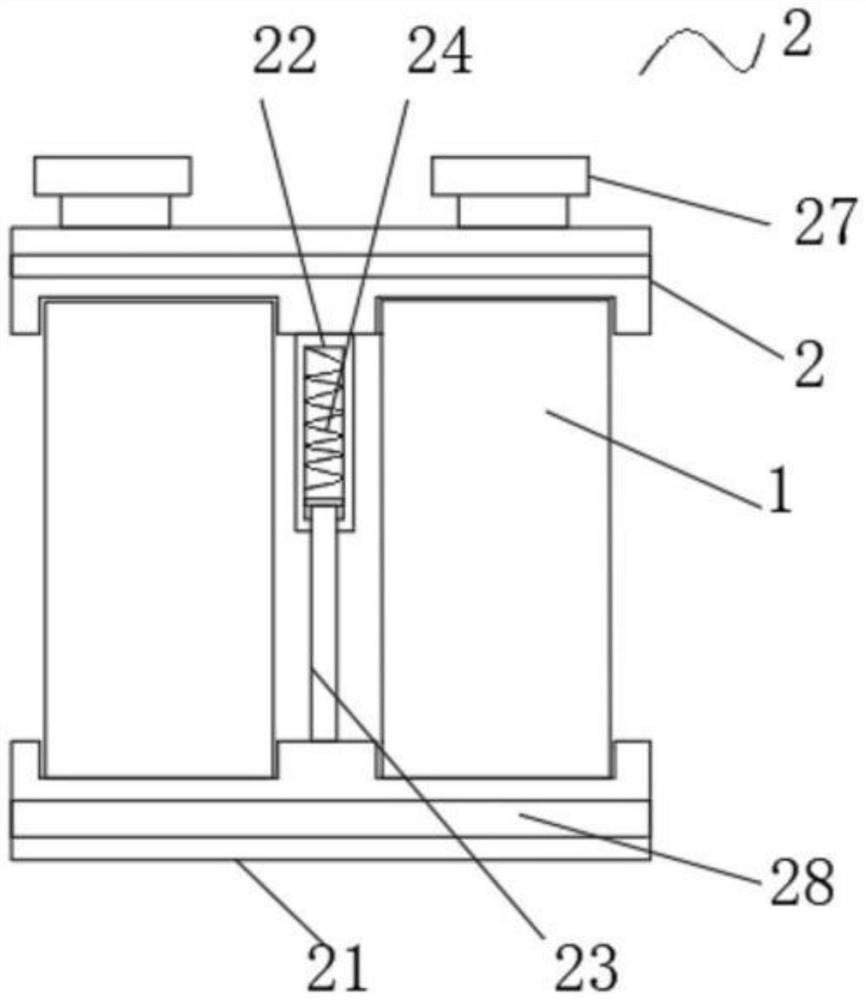

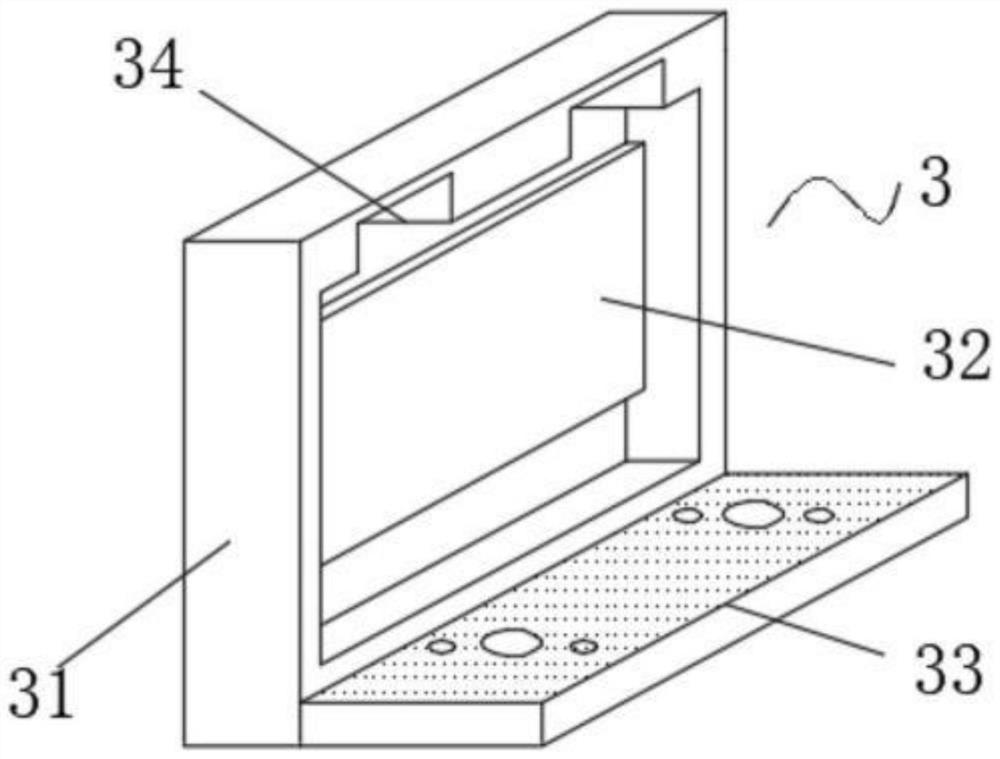

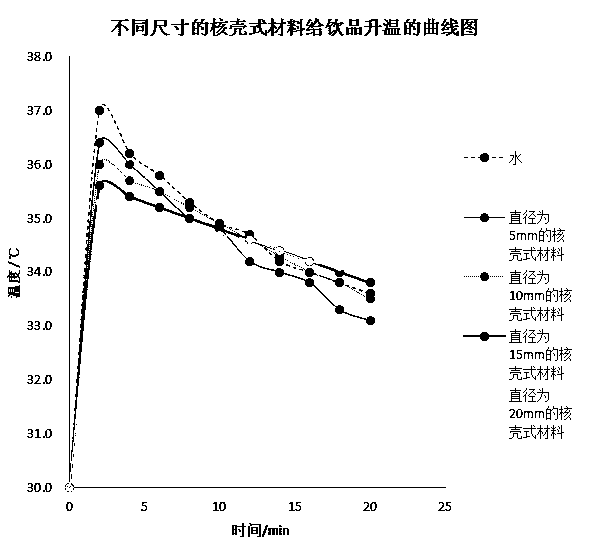

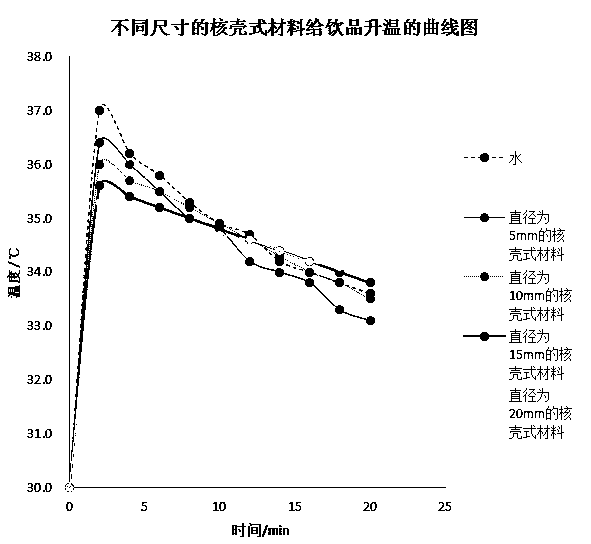

A preparation method of core-shell material for beverage insulation

The invention discloses a method for preparing a core-shell material for heat preservation of beverages. The core-shell material uses aluminum or magnesium inorganic materials as the core and silicate glass as the shell for wrapping, and can be passed through molds of different shapes. Make it into different art forms. Putting the material directly into hot drinks after heating can greatly extend the heat preservation time of the drinks; the material is non-toxic and harmless, does not absorb water, does not dissolve, has no side effects on drinks, and can be recycled and reused.

Owner:FUZHOU UNIV

Antistatic expanded perlite and phenolic resin composite insulation board and preparation method thereof

The invention discloses an antistatic expansion perlite phenolic resin composite insulation board, which is made of the following raw materials in parts by weight: polyphenylene ether sulfonate lithium 1.3-1.8, magnesium carbonate 2.3-2.6, nano carbon sol 3.6-3.9, mustard Acid amide 0.4‑0.6, expanded perlite 55‑57, phenolic resin 40‑42, curing agent HMTA4‑4.1, steel fiber 2‑2.3, tetraethyl orthosilicate 10‑11, 85wt% ammonia water, absolute ethanol, Deionized water 160‑180, appropriate amount of n-hexane, nano-polytetrafluoroethylene 4‑4.5, cumene peroxide 0.1‑0.2, trifluoroethyl acrylate 3‑3.5. The invention uses polyphenylene ether sulfonate lithium, magnesium carbonate, nano-carbon sol, and erucamide to make the heat preservation board have good antistatic properties, and to improve the heat resistance and compressive strength of the heat preservation board.

Owner:DANGTU COUNTY KEHUI TRADING

A foamed concrete insulation board

ActiveCN112627370BDecreased thermal insulationImprove protectionLivestock managementCuttersFoam concreteArchitectural engineering

Owner:联海装配式建材有限公司

Heat-resistant expanded perlite and phenolic resin composite insulation board and preparation method thereof

The invention discloses a heat-resistant expanded perlite and phenolic resin composite insulation board, which is prepared from the following raw materials (by weight): 1.3-1.8 parts of high aluminium wool, 2.5-2.8 parts of cellulose ether, 1-1.2 parts of phenolic resin closed-cell microspheres, 0.4-0.6 part of multiwalled carbon nanotube, 55-57 parts of expanded perlite, 40-42 parts of phenolic resin, 4-4.1 parts of a curing agent HMTA, 2-2.3 parts of steel fiber, 10-11 parts of tetraethyl orthosilicate, a proper amount of 85wt% ammonia water, a proper amount of anhydrous ethanol, 160-180 parts of deionized water, a proper amount of n-hexane, 4-4.5 parts of nano-polytetrafluoroethylene, 0.1-0.2 part of dicumyl peroxide and 3-3.5 parts of 2,2,2-trifluoroethyl acrylate. By using high aluminium wool and multiwalled carbon nanotube, heat resistance and radiation resistance of the insulation board are raised. By using cellulose ether and phenolic resin pore-closed microspheres, toughness, tensile strength and heat insulating property of the insulation board are enhanced.

Owner:DANGTU COUNTY KEHUI TRADING

Preparation method of core-shell material for heat preservation of drinks

The invention discloses a preparation method of a core-shell type material for heat preservation of drinks. The core-shell type material takes aluminum or magnesium inorganic materials as a core and silicate glass as a shell for wrapping, and can be made into different artistic forms through molds with different shapes. The material can be directly put into hot drinks after being heated, thus greatly prolonging the heat preservation time of the drinks. The material is nontoxic and harmless, does not absorb water, does not dissolve, has no side effects on drinks, and can be recycled.

Owner:FUZHOU UNIVERSITY

Preparation method of hard erosion resistant alumina fiberboard hearth material

The invention relates to a preparation method of a hard erosion resistant alumina fiberboard hearth material. Directed at the existing problems of loose structure, no resistance to high temperature and erosion, and short service life during application of current alumina fiberboards as high temperature electric furnace hearth materials, the invention adds a lot of alumina micropowder into aluminafibers and adds a silica sol as a binder. The materials are mixed into mud, which is then poured into a die for moulding. After natural air drying, drying, cutting processing and high temperature calcining, an erosion resistant, bending resistant, hard and high strength alumina fiberboard hearth material can be obtained. Used as a high temperature electric furnace hearth material, the hard erosion resistant alumina fiberboard hearth material of the invention can have a service life improved by over 6 times.

Owner:江苏中能赛创智能装备科技有限公司

High-strength gypsum-based sound insulation and thermal insulation machine spray mortar and composite thermal insulation layer

The invention discloses high-strength-gypsum-based sound insulation and thermal insulation machine spraying mortar, belongs to the technical field of building and ornament materials and preparation, and solves the problem that in the prior art, gypsum-based mortar is not applicable to machine spraying construction. The high-strength-gypsum-based sound insulation and thermal insulation machine spraying mortar is characterized by being prepared from the following components in parts by weight: 800-850 parts of white high-strength gypsum, 30-60 parts of hollow glass beads, 30-60 parts of light glass beads, 60-120 parts of hydrophobic type dispersible latex powder, 3-5 parts of cellulose ether, 2-10 parts of bentonite, 4.0-5.5 parts of gypsum retarder and 900-1,000 parts of water. The gypsum-based mortar has the advantages of high liquidity and high stability, is applied to machine spraying construction, has a good thermal insulation effect after construction, and is high in sound insulation performance and water resistance. The invention correspondingly discloses a preparation method of the high-strength-gypsum-based sound insulation and thermal insulation machine spraying mortar, anda composite thermal insulation layer applying the machine spraying mortar and a construction method of the composite thermal insulation layer.

Owner:苏州高新大乘低碳环保新材发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com