A method of making insulation board by using foam glass waste

A foam glass and foam glass powder technology, applied in chemical instruments and methods, solid waste management, sustainable waste treatment, etc., can solve the problems of inability to recycle and utilize, waste pollution, etc., and achieve the effect of economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0010] A method for making thermal insulation boards from waste foam glass, which is characterized in that foam glass fragments, foam glass powder, cellulose, rubber powder, cement and lime are mixed evenly with water, cast into a rectangular body by using a mold, and cut into pieces after natural drying Plate-shaped recycled material finished product, the weight ratio of the above foam glass fragments is 64%, the block diameter is 30mm-150mm, the weight ratio of foam glass powder is 16%, the weight ratio of cellulose is 0.24%, the weight ratio of rubber powder The weight ratio of cement is 0.12%, the weight ratio of cement is 15%, and the weight ratio of lime is 4.64%.

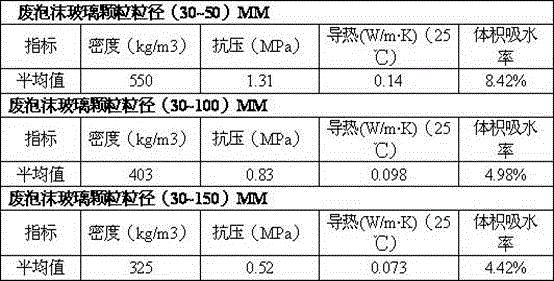

[0011] Above-mentioned embodiment has adopted the cellular glass fragment of different sizes,

[0012] Table 1

[0013]

Embodiment 2

[0015] Divide the rectangular body poured by the above method into recycled material sheets, place two recycled material sheets on the upper layer and the lower layer, sandwich a layer of non-recycled material sheets in the middle, and glue them together to make a finished composite insulation board. The indicators are shown in Table 2:

[0016] Table 2

[0017] index Density (kg / m3) Compression (MPa) Thermal conductivity (W / m·K) (25°C) Volume water absorption average value 352 0.75 0.074 4.62%

Embodiment 3

[0019] Divide the rectangular body poured by the above method into recycled material sheets, place two non-recycled material sheets on the upper layer and the lower layer, sandwich a layer of recycled material sheets in the middle, and bond them with glue to make a finished composite insulation board.

[0020] table 3

[0021] index Density (kg / m3) Compression (MPa) Thermal conductivity (W / m·K) (25°C) Volume water absorption average value 284 0.64 0.062 4.23%

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com