Preparation method of core-shell material for heat preservation of drinks

A core-shell and beverage technology is applied in the field of preparation of core-shell materials for beverage heat preservation, and can solve problems such as affecting taste, dilution and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

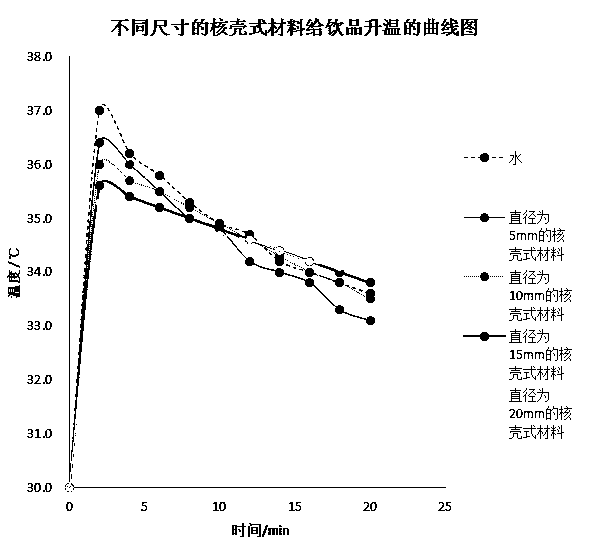

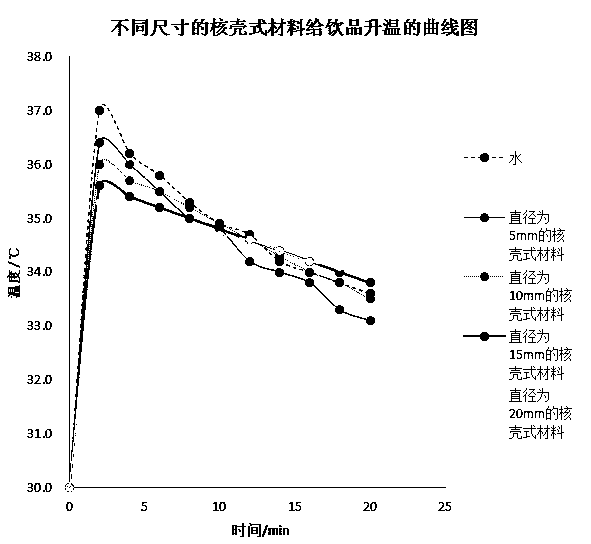

Embodiment 1

[0034] (1) Raw material preprocessing: crush, grind and dry quartz sand, soda ash, feldspar, limestone, dolomite, fluorite, barite and chrome slag respectively;

[0035] (2) Ingredients: Quartz sand: soda ash: limestone: feldspar: fluorite: dolomite: barite: chrome slag = 51.57: 15.82: 15.62: 6.25: 5.47: 1.76: 1.56 : The ratio of 1.95 is weighed and mixed in the mixer;

[0036] (3) Melting: place the mixed material in a pool kiln and heat it at a high temperature of 1200°C to form a uniform, bubble-free liquid glass that meets the molding requirements;

[0037] (4) Forming: The melted liquid glass is molded into a hollow glass sphere with a small hole in diameter of 5 mm. The inner wall thickness of the hollow glass product is 0.5 mm, and the hollow cavity accounts for 80% of the volume of the glass product. The hole diameter is 1mm;

[0038] (5) filling: aluminum sulfate is filled into the hollow cavity of the hollow glass sphere, and the filling amount accounts for 80% of ...

Embodiment 2

[0044] (1) Raw material preprocessing: crush, grind and dry quartz sand, soda ash, feldspar, limestone, dolomite, fluorite, barite and chrome slag respectively;

[0045] (2) Ingredients: Quartz sand: soda ash: limestone: feldspar: fluorite: dolomite: barite: chrome slag = 51.57: 15.82: 15.62: 6.25: 5.47: 1.76: 1.56 : The ratio of 1.95 is weighed and mixed in the mixer;

[0046] (3) Melting: place the mixed material in a crucible kiln and heat it at a high temperature of 1600°C to form a uniform, bubble-free liquid glass that meets the molding requirements;

[0047] (4) Forming: The molten glass is molded into a hollow glass sphere with a small hole in diameter of 10mm. The inner wall thickness of the hollow glass product is 1mm, and the hollow cavity accounts for 80% of the volume of the glass product. The hole diameter is 2mm;

[0048] (5) filling: aluminum sulfate is filled into the hollow cavity of the hollow glass sphere, and the filling amount accounts for 80% of the vo...

Embodiment 3

[0054] (1) Raw material preprocessing: crush, grind and dry quartz sand, soda ash, feldspar, limestone, dolomite, fluorite, barite and chrome slag respectively;

[0055] (2) Ingredients: Quartz sand: soda ash: limestone: feldspar: fluorite: dolomite: barite: chrome slag = 51.57: 15.82: 15.62: 6.25: 5.47: 1.76: 1.56 : The ratio of 1.95 is weighed and mixed in the mixer;

[0056] (3) Melting: Place the mixed materials in a pool kiln for heating at a high temperature of 1600°C to form a uniform, bubble-free liquid glass that meets the molding requirements;

[0057] (4) Forming: The melted liquid glass is molded into a hollow glass sphere with a small hole in diameter of 15 mm. The inner wall thickness of the hollow glass product is 1.5 mm, and the hollow cavity accounts for 80% of the volume of the glass product. The hole diameter is 3mm;

[0058] (5) filling: aluminum sulfate is filled into the hollow cavity of the hollow glass sphere, and the filling amount accounts for 80% o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com