Moisture-proof and high strength IC carrier tape material

A high-strength, carrier tape technology, applied in packaging and other directions, can solve problems such as easy breakage, scrapping, device damage, etc., and achieve the effects of good aging resistance, good toughness and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A moisture-proof high-strength IC carrier tape material, the technical solution adopted is:

[0027] According to parts by mass:

[0028] Polystyrene, 55kg;

[0029] High-density polyethylene, 5kg;

[0030] Silicone grafted polyethylene polypropylene fiber, 15kg;

[0031] Aging-resistant linear triembedded copolymer, 3kg;

[0032] Toughener: 3kg;

[0033] Antioxidant: 0.3kg;

[0034] After mixing the above materials evenly, use a twin-screw extruder to granulate to obtain granulated material, and then mix and extrude the granulated material and 3% to 5% black masterbatch to form a carrier tape material;

[0035] The IC carrier tape is divided into three layers, upper, middle and lower, the upper layer and the lower layer are the surface PS conductive masterbatch, the surface PS conductive masterbatch: carrier tape material: PS conductive masterbatch = 1:8:1.

[0036] Described organosilicon-grafted polyethylene polypropylene fibers are grafted according to the fol...

Embodiment 2

[0040] A moisture-proof high-strength IC carrier tape material, the technical solution adopted is:

[0041] According to parts by mass:

[0042] Polystyrene, 60kg;

[0043] High-density polyethylene, 10kg;

[0044] Silicone grafted polyethylene polypropylene fiber, 22kg;

[0045] Aging-resistant linear triembedded copolymer, 2kg;

[0046] Toughener: 1kg;

[0047] Antioxidant: 0.5kg.

[0048] After mixing the above materials evenly, use a twin-screw extruder to granulate to obtain granulated material, and then mix and extrude the granulated material and 3% to 5% black masterbatch to form a carrier tape material;

[0049] The IC carrier tape is divided into three layers, upper, middle and lower, the upper layer and the lower layer are the surface PS conductive masterbatch, the surface PS conductive masterbatch: carrier tape material: PS conductive masterbatch = 1:8:1.

[0050] Described organosilicon-grafted polyethylene polypropylene fiber is prepared according to the fol...

Embodiment 3

[0054] A moisture-proof high-strength IC carrier tape material, the technical solution adopted is:

[0055] According to parts by mass:

[0056] Polystyrene, 75kg;

[0057] High-density polyethylene, 15kg;

[0058] Silicone grafted polyethylene polypropylene fiber, 30kg;

[0059] Aging-resistant linear triembedded copolymer, 8kg;

[0060] Toughener: 5kg;

[0061] Antioxidant: 0.8kg.

[0062] After mixing the above materials evenly, use a twin-screw extruder to granulate to obtain granulated material, and then mix and extrude the granulated material and 3% to 5% black masterbatch to form a carrier tape material;

[0063] The IC carrier tape is divided into three layers, upper, middle and lower, the upper layer and the lower layer are the surface PS conductive masterbatch, the surface PS conductive masterbatch: carrier tape material: PS conductive masterbatch = 1:8:1.

[0064] Described SBPC: Silicone grafted polyethylene polypropylene fibers are grafted according to the fol...

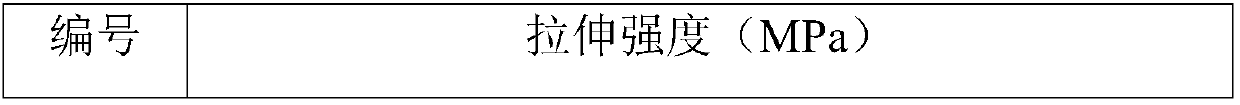

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com