Inorganic lightweight aggregate insulation board and preparation method thereof

A technology of inorganic light aggregates and thermal insulation boards, which is applied in the field of building thermal insulation materials, can solve problems such as weakening of bonding strength, affecting the strength of thermal insulation boards, and loss of waterproof effect of thermal insulation boards, so as to achieve the effect of preventing the decline of thermal insulation performance and increasing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

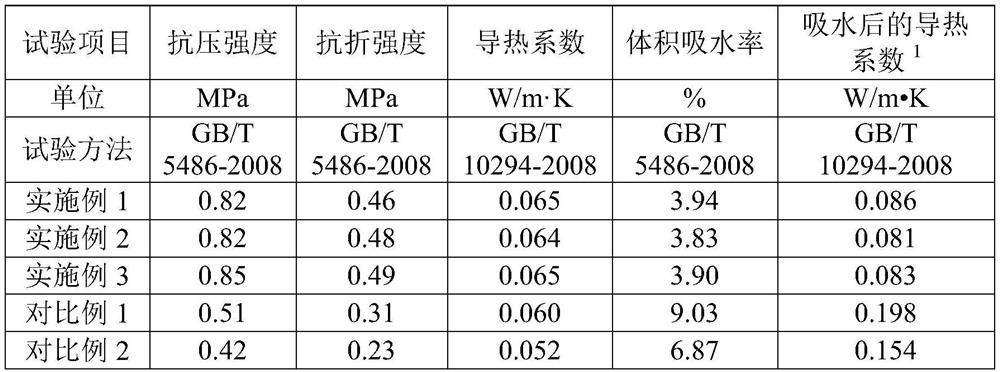

Examples

preparation example Construction

[0038] The preparation method of described modified expanded perlite is as follows:

[0039] (1.1) Grafting vinyl: disperse the expanded perlite into ethanol, the mass volume ratio of the expanded perlite to ethanol is 1g:10-15mL, add vinyltrimethoxysilane, the expanded perlite and ethylene The mass ratio of trimethoxysilane is 1:0.8-1.0, after mixing evenly, stirring at 70-80°C for 3-4h, filtering, washing and drying to obtain vinyl-modified expanded perlite;

[0040](1.2) Coating hydrophobic layer: Add vinyl-modified expanded perlite, methyl methacrylate and 3-amino-1-propylene with a mass ratio of 1:0.3-0.4:0.1-0.2 into ethanol, and the vinyl The mass volume ratio of base-modified expanded perlite to ethanol is 1g:25-30mL. After uniform dispersion, heat to 70-80°C, and add the ethanol solution of azobisisobutyronitrile (among them, azo The mass volume ratio of diisobutyronitrile and ethanol is 1g:15-20mL), the mass ratio of described azobisisobutyronitrile and methyl metha...

Embodiment 1

[0049] An inorganic lightweight aggregate insulation board, comprising the following raw materials in parts by weight: 390 parts of modified expanded perlite, 90 parts of Portland cement, 25 parts of waterproof glue, 1.1 parts of curing powder, 0.3 parts of polypropylene fiber, and 1 part of water . The waterproof glue is polyurethane adhesive; the curing powder is epoxy resin.

[0050] The preparation method of described modified expanded perlite is as follows:

[0051] (1.1) Grafting vinyl: disperse the expanded perlite in ethanol, the mass volume ratio of the expanded perlite to ethanol is 1g:10mL, add vinyl trimethoxysilane, the expanded perlite and vinyl trimethyl The mass ratio of oxysilane is 1:0.8. After mixing evenly, stir at 80°C for 3 hours, filter, wash, and dry to obtain vinyl-modified expanded perlite;

[0052] (1.2) Coating hydrophobic layer: adding vinyl modified expanded perlite, methyl methacrylate and 3-amino-1-propylene with a mass ratio of 1:0.3:0.1 to e...

Embodiment 2

[0061] An inorganic lightweight aggregate insulation board, comprising the following raw materials in parts by weight: 400 parts of modified expanded perlite, 100 parts of Portland cement, 27 parts of waterproof glue, 1.3 parts of curing powder, 0.4 parts of polypropylene fiber, and 1.5 parts of water . The waterproof glue is polyurethane adhesive; the curing powder is epoxy resin.

[0062] The preparation method of described modified expanded perlite is as follows:

[0063] (1.1) Grafting vinyl: disperse the expanded perlite in ethanol, the mass volume ratio of the expanded perlite to ethanol is 1g:10mL, add vinyl trimethoxysilane, the expanded perlite and vinyl trimethyl The mass ratio of oxysilane is 1:0.9. After mixing evenly, stir at 75°C for 3.5h, filter, wash, and dry to obtain vinyl-modified expanded perlite;

[0064] (1.2) Coating hydrophobic layer: Add vinyl-modified expanded perlite, methyl methacrylate and 3-amino-1-propylene with a mass ratio of 1:0.35:0.15 into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com