High-strength gypsum-based sound insulation and thermal insulation machine spray mortar and composite thermal insulation layer

A technology of sound insulation and heat preservation and machine spraying mortar, which is applied in the field of building decoration and construction, can solve the problems of high viscosity of thermal insulation materials, high labor intensity, and great influence of thermal insulation material viscosity, and achieves high bonding fastness and low labor intensity. , the effect of efficient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

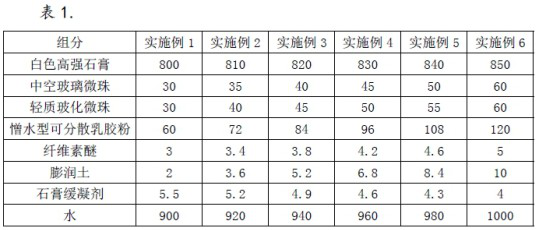

[0072] Examples 1-6 all relate to a high-strength gypsum-based sound-insulating and heat-insulating mortar, and the contents of each component are shown in the following table in parts by weight:

[0073]

[0074] Among them, the white high-strength gypsum is high-strength gypsum with a flexural strength greater than 5MPa; the true density of the hollow glass beads is 0.4g / cm 3 , particle diameter is 114 μ m; The particle diameter of lightweight vitrified microbead is 220 μ m; Gypsum retarder is commercially available common gypsum retarder, and the gypsum retarder used in the embodiment 1-6 is QH80 efficient gypsum retarder Coagulant (Shanghai Qinhe Chemical Co., Ltd.); Hydrophobic dispersible latex powder can be selected polyvinyl acetate latex powder or polyacrylate latex powder, all selects polyvinyl acetate latex powder for use in embodiment 1-6; Bentonite selects for use Na-based bentonite, lithium-based bentonite or calcium-based bentonite can be used, and sodium-bas...

Embodiment 7-18

[0079] Embodiments 7-18 all relate to a kind of high-strength gypsum-based sound insulation and thermal insulation machine spray mortar, and all include:

[0080] White high-strength gypsum 825 parts

[0081] Hollow glass microspheres 45 parts

[0082] Lightweight vitrified microbeads 45 parts

[0083] 90 parts of polyvinyl acetate latex powder

[0084] 4 parts hydroxyethyl methylcellulose ether

[0085] Sodium bentonite 6 parts

[0086] QH80 efficient gypsum retarder 4 parts

[0087] 950 parts of water;

[0088] Among them, the flexural strength of white high-strength gypsum is greater than 5MPa, and the viscosity of hydroxyethyl methylcellulose ether is 170000MPa·s.

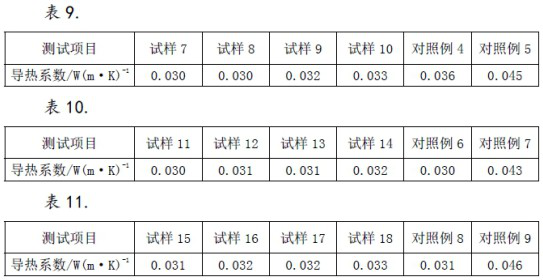

[0089] The difference between Examples 7-18 is that the selected hollow glass microspheres and light vitrified microspheres are different, as shown in the following table,

[0090]

Embodiment 19

[0092] A method for preparing high-strength gypsum-based sound-insulating and heat-insulating machine spray mortar, specifically comprising the following steps:

[0093] Step 1, take each component according to embodiment 1;

[0094] Step 2. First, add light vitrified microspheres and polyvinyl acetate latex powder into the blender, and stir evenly;

[0095] Step 3, add white high-strength gypsum, hydroxyethyl methylcellulose ether and sodium bentonite to the mixer and continue stirring;

[0096] Step 4, then, add hollow glass microspheres and gypsum retarder to the mixer, and stir evenly;

[0097] Step 5. Finally, add water and stir evenly to obtain the high-strength gypsum-based sound insulation and thermal insulation machine spray mortar of Example 1;

[0098] The stirring speed in step 2, step 3, step 4 and step 5 is 800rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com