Sand-wood composite material and preparation method thereof

A technology of composite materials and silica sand, applied in applications, kitchen cabinets, furniture parts, etc., can solve the problems of poor thermal insulation performance of building materials, poor anti-oil pollution effect, and short thermal insulation durability, etc., to achieve improved thermal insulation performance, stable structure, and improved The effect of binding density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

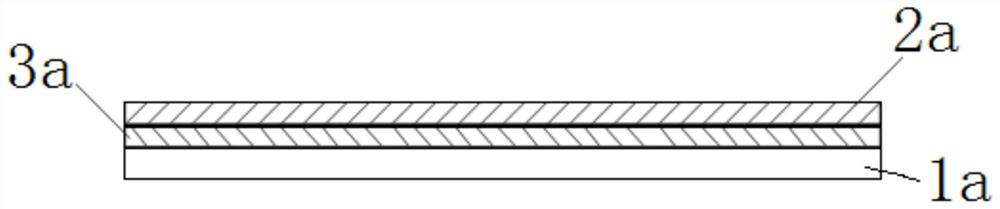

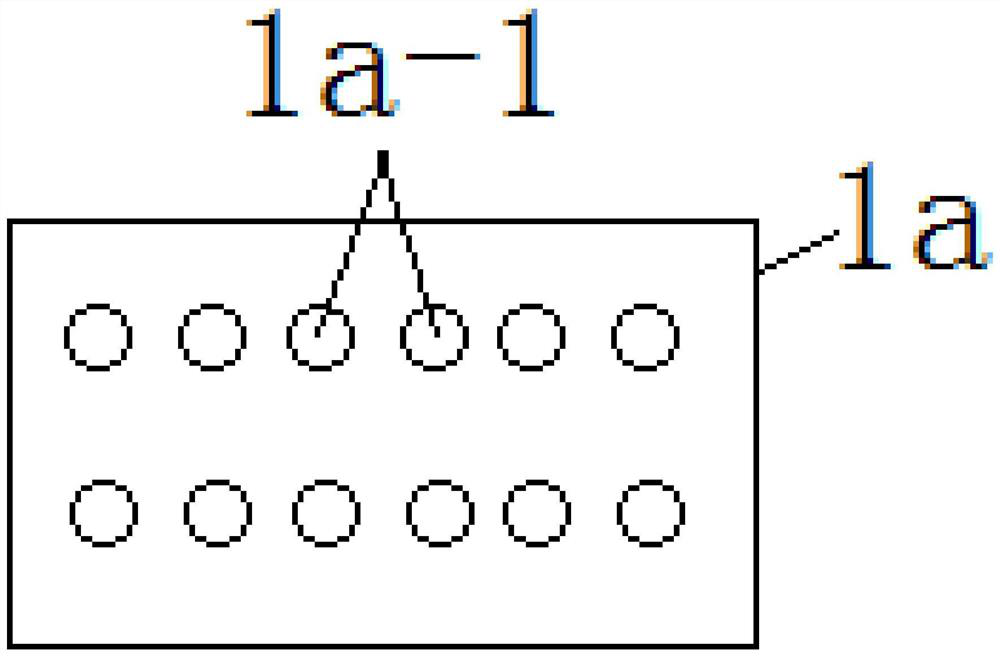

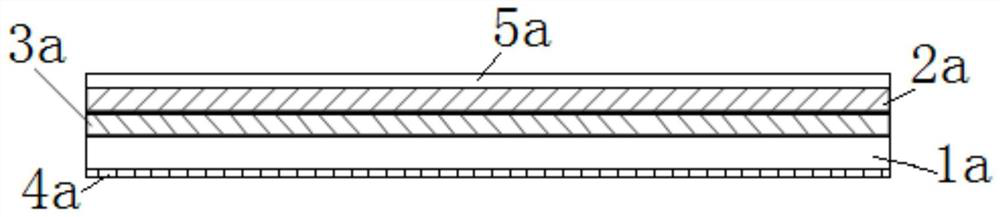

Image

Examples

Embodiment 1

[0085] This embodiment provides a thermal insulation type sand-wood composite material, which is composed of the following raw materials: 70g of river sand with a particle size of 25 meshes, 25g of phenolic resin, 20g of polystyrene, 6g of silane coupling agent KH550, and glass fibers with a length of 9mm 25g, 5g of attapulgite, 12g of titanium dioxide with a particle size of 70nm;

[0086] The preparation method of the above-mentioned thermal insulation type sand-wood composite material comprises the following steps:

[0087] 1) Mix river sand, phenolic resin, polystyrene, titanium dioxide and silane coupling agent KH550, and heat to 160°C under nitrogen protection to prepare the first slurry;

[0088] 2) adding glass fiber and attapulgite to the first slurry, and stirring and mixing at a speed of 200r / min for 1.2h to obtain a second slurry;

[0089] 3) Carry out forming treatment and cooling treatment on the second slurry in sequence, the temperature of the forming treatmen...

Embodiment 2

[0091] This embodiment provides a kind of thermal insulation sand-wood composite material, which is composed of the following raw materials: 90g of aeolian sand with a particle size of 20 meshes, 20g of phenolic resin, 25g of polystyrene, 5g of titanate coupling agent TMC-201, length 20g of glass fiber with a diameter of 10mm, 6g of attapulgite, and 8g of titanium dioxide with a particle size of 60nm;

[0092] The preparation method of the above-mentioned thermal insulation type sand-wood composite material comprises the following steps:

[0093] 1) Mix aeolian sand, phenolic resin, polystyrene, titanium dioxide and titanate coupling agent TMC-201, and heat to 200°C under nitrogen protection to prepare the first slurry;

[0094] 2) adding glass fiber and attapulgite to the first slurry, and stirring and mixing for 1.5 hours at a rotation speed of 150r / min to obtain a second slurry;

[0095] 3) Carry out molding treatment and cooling treatment on the second slurry in sequence,...

Embodiment 3

[0097] This embodiment provides a thermal insulation sand-wood composite material, which is composed of the following raw materials: 50g of sea sand with a particle size of 30 mesh, 30g of phenolic resin, 15g of polystyrene, 8g of aluminate coupling agent, and glass with a length of 8mm. 30g of fiber, 3g of attapulgite, 15g of titanium dioxide with a particle size of 80nm;

[0098]The preparation method of the above-mentioned thermal insulation type sand-wood composite material comprises the following steps:

[0099] 1) Mix sea sand, phenolic resin, polystyrene, titanium dioxide and aluminate coupling agent, and heat to 120°C under nitrogen protection to prepare the first slurry;

[0100] 2) adding glass fiber and attapulgite to the first slurry, and stirring and mixing for 1 hour at a rotation speed of 250r / min to obtain a second slurry;

[0101] 3) Carry out forming treatment and cooling treatment on the second slurry in sequence, the temperature of the forming treatment is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com