Fabricated building external wall thermal insulation construction process

A technology for building exterior walls and construction techniques, which is applied in the direction of construction, heat preservation, and building components. It can solve the problems that affect the reliability of building exterior walls, the walls are prone to gaps, and the heat preservation effect is reduced, so as to avoid the decline of heat preservation performance and ensure Thermal insulation performance, the effect of improving thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

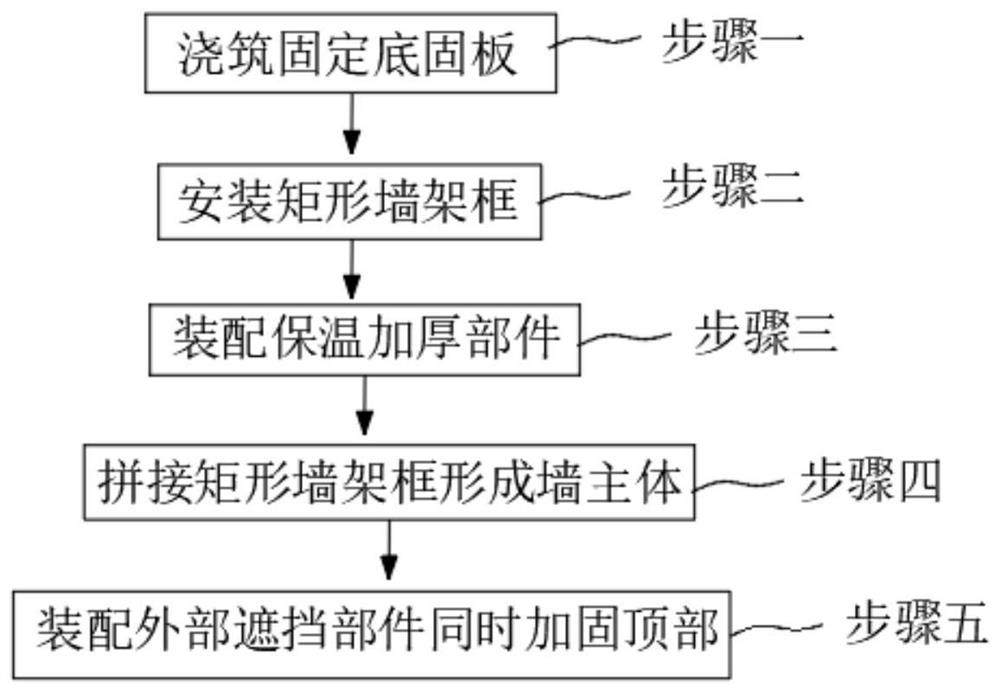

[0058] Example 1, please refer to Figure 1-10 , the prefabricated building exterior wall insulation construction process, including the following process steps:

[0059] Step 1, pouring and fixing the bottom fixing plate 1, fixing the bottom of the bottom fixing plate 1 in the outer wall of the prefabricated building on the U-shaped pouring rib 10, and then pouring the U-shaped pouring rib 10 at the construction position through concrete, and keeping the bottom solid during pouring. Plate 1 is in a horizontal state;

[0060] Step 2, install the rectangular wall frame 31, and fix the rectangular wall frame 31 of the wall frame insulation unit 3 in the outer wall of the prefabricated building on the upper side of the bottom fixing plate 1 through the wall panel bottom fixing assembly 2 at the bottom of the outer wall of the prefabricated building. ;

[0061] Step 3, assemble the thermal insulation and thickening components, assemble the dismantling board 32 and the thermal in...

Embodiment 2

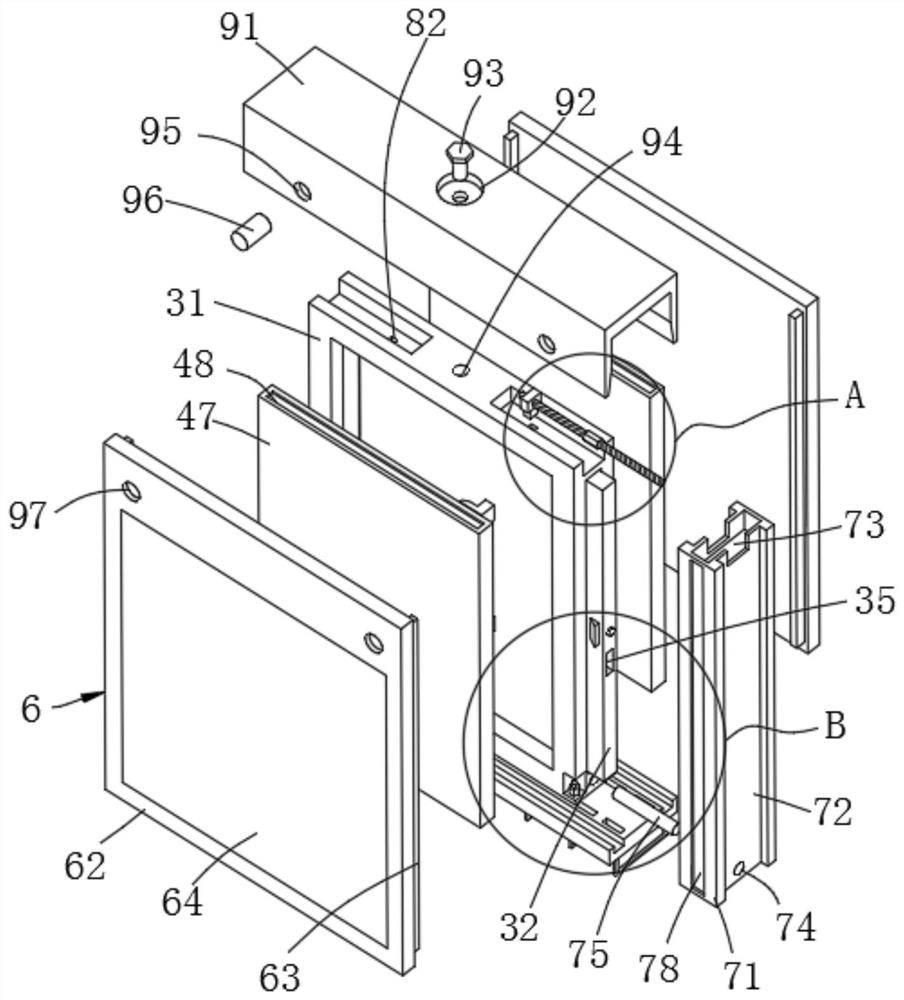

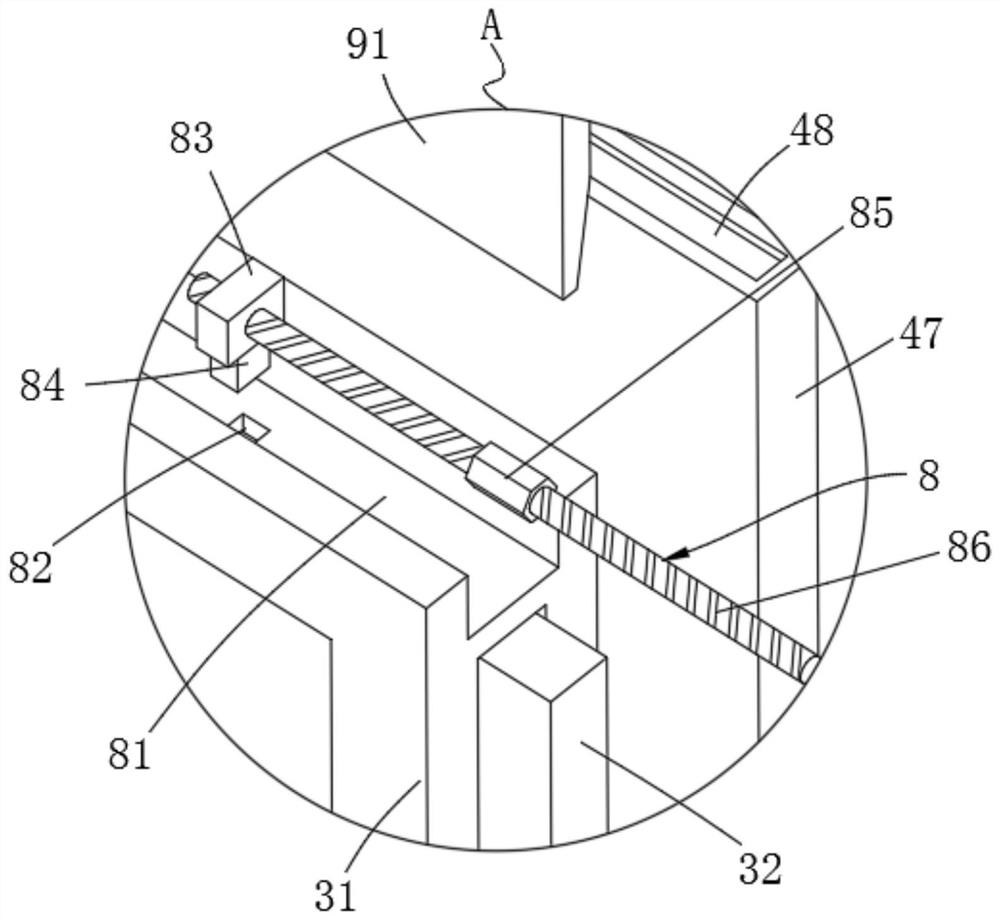

[0085] Example 2, please refer to figure 2 , Figure 5 and Figure 9 , the prefabricated building exterior wall thermal insulation construction process, this embodiment is a further description of the prefabricated building exterior wall in the first embodiment;

[0086] The outer shielding unit 6 includes a side horizontal groove 61, a shielding plate 62, a sealing strip 63, a decorative plate 64, and a buffering sliding plate 65. The upper side of the bottom fixing plate 1 is located at the front and rear sides of the bottom of the rectangular wall frame 31. Side and horizontal grooves 61, a shielding plate 62 is provided on the side of the thermal insulation thickening plate assembly away from the rectangular wall frame 31. Vertical sealing strips 63 are respectively fixed at both ends of the side. The sealing strips 63 are engaged with the sealing vertical grooves 78. The side of the shielding plate 62 away from the rectangular wall frame 31 is provided with a rectangul...

Embodiment 3

[0090] Example three, please refer to figure 2 and 10 , the prefabricated building exterior wall thermal insulation construction process, this embodiment is a further description of the prefabricated building exterior wall in the first embodiment;

[0091] The outer wall top-fixing sealing unit 9 includes a top-fixing cover plate 91 and a fixing component. The top-fixing cover plate 91 is fixed on the top of the rectangular wall frame 31, and the front and rear sides of the top-fixing cover plate 91 are respectively fixedly connected by the fixing components. The top of the shielding plate 62 . The top fixing cover plate 91 can wrap and fix the top of the rectangular wall frame 31 and the tops of the front and rear shielding plates 62 , so as to improve the sealing performance inside the wall and also increase the strength.

[0092] The fixing assembly includes a sinker 92, a reinforced bolt 93, a reinforced screw hole 94, a side hole 95, a pin 96, a pin hole 97, an inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com