High Speed Milling Tool

A high-speed milling and cutting tool technology, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of long adjustment time, complex tool structure, unstable structure of high-speed rotation of the tool, etc., to improve cutting efficiency, convenient adjustment, structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

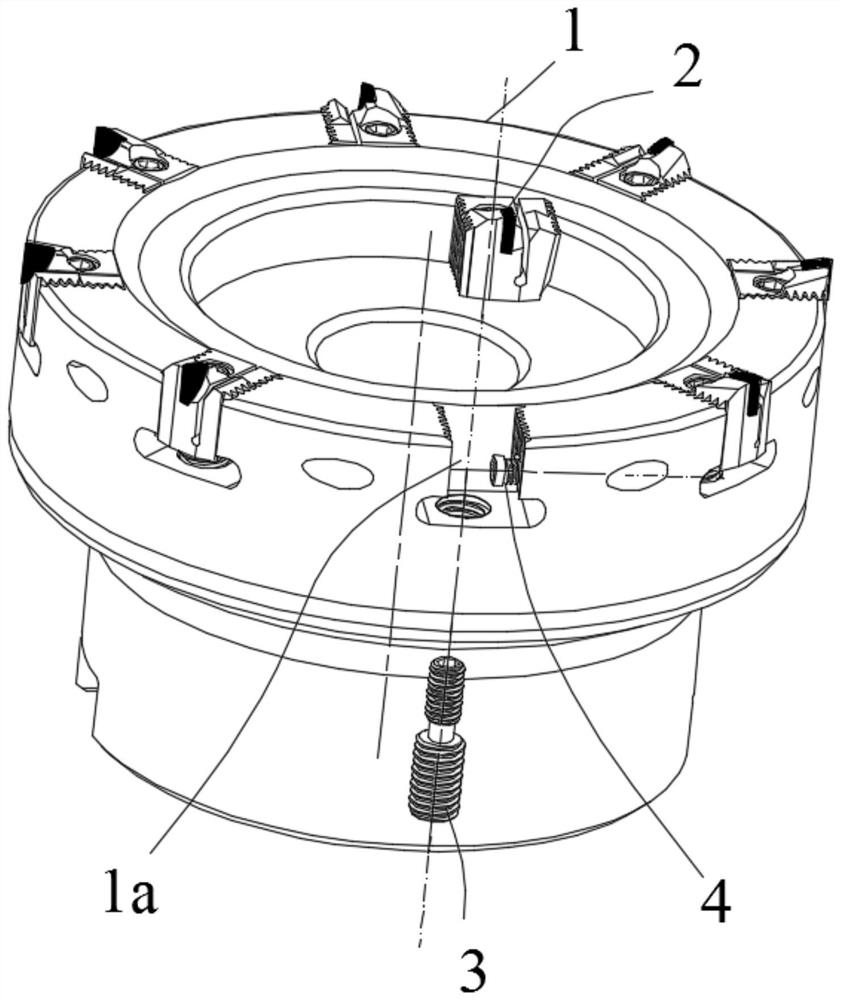

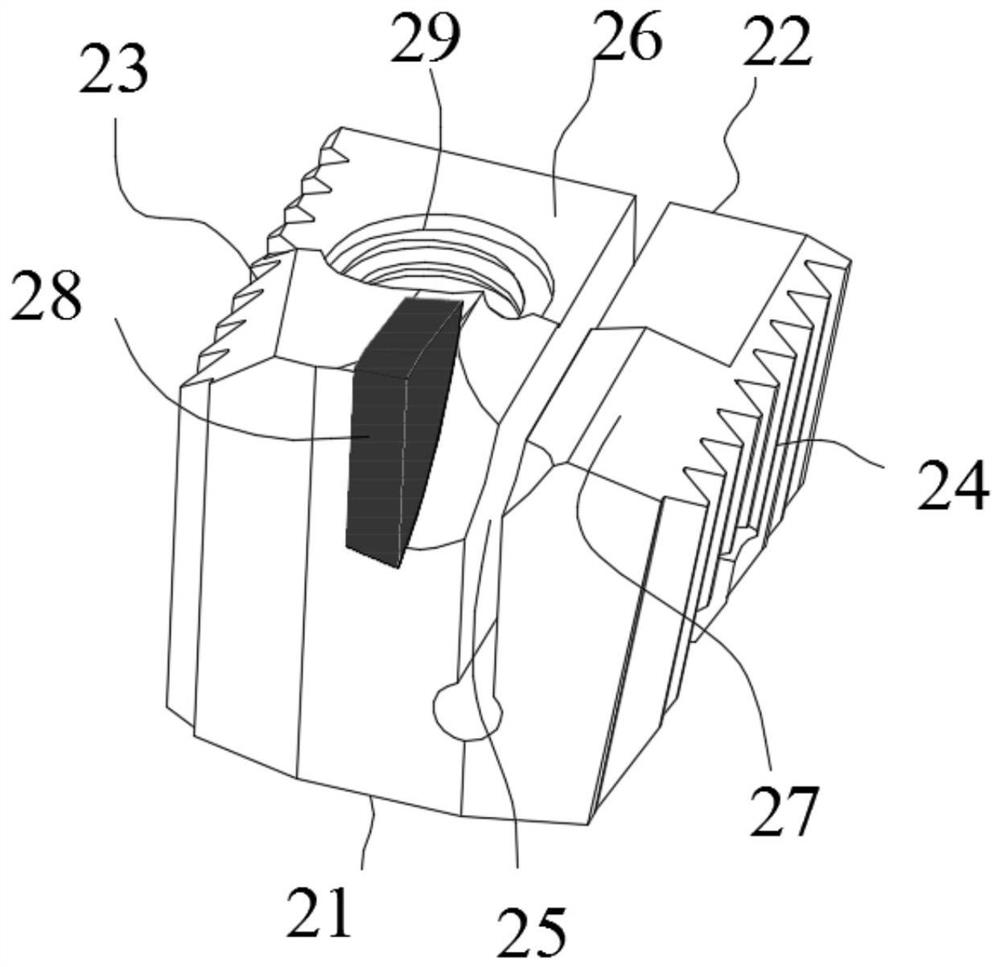

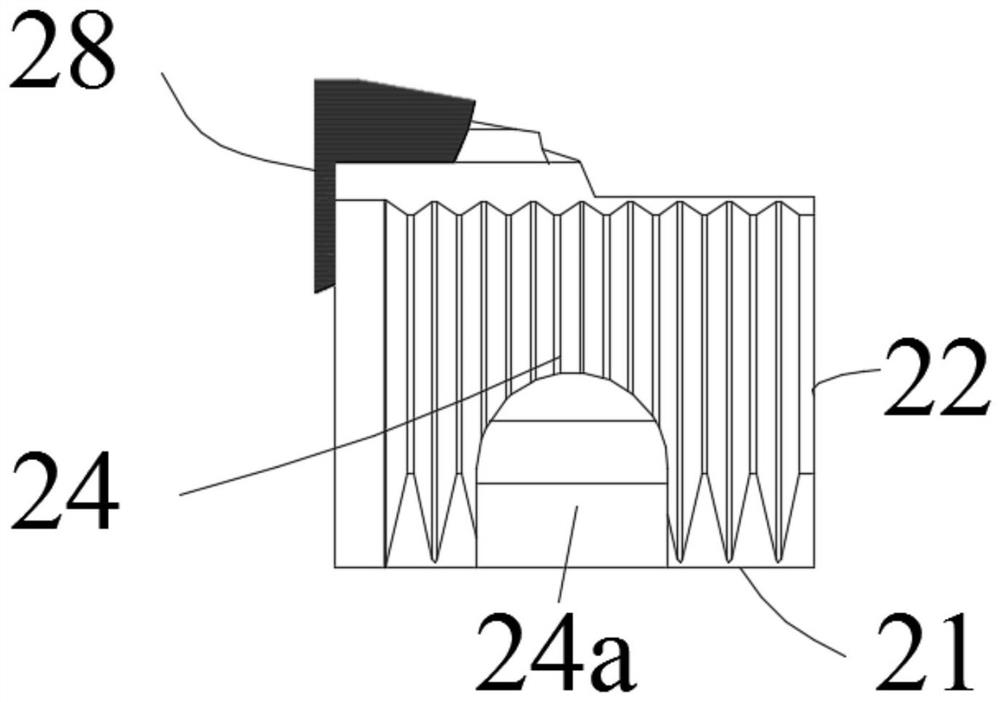

[0045] like Figure 1 to Figure 7 As shown, the embodiment of the present invention provides a high-speed milling tool, including: a cutter body 1, the cutter body 1 is a disc-shaped cutter body, a plurality of knife grooves 1a are provided on the cutter body 1, and the cutter body 1 The slot 1a is used to install the cutting unit; the cutting unit includes a tool holder 2, a driving screw 3 and an auxiliary pressing screw 4; The first tangential surface 13 of the knife groove and the second tangential surface 14 of the knife groove are formed. 23 and the second tangential surface 24 of the knife holder; the axial surface 11 of the knife groove, the radial surface 12 of the knife groove, the first tangential surface 13 of the knife groove and the second tangential surface 14 of the knife groove are respectively connected with the knife holder The axial surface 21, the radial surface 22 of the tool holder, the first tangential surface 23 of the tool holder and the second tange...

Embodiment 2

[0064] like Figure 14 and 15 As shown, embodiment 2 of the present invention provides a kind of high-speed milling cutter, comprises: cutter body 1, and described cutter body 1 is disc-shaped cutter body, and described cutter body 1 is uniformly provided with a plurality of sipes 1a, so The sipe 1a is used to install the cutting unit; the cutting unit includes a tool holder 2, a driving screw 3 and an auxiliary compression screw 4; each of the sipe 1a is composed of a sipe axial surface 11, a sipe radial surface 12. The first tangential surface 13 of the knife groove and the second tangential surface 14 of the knife groove are formed. To the surface 23 and the second tangential surface 24 of the knife holder; the axial surface 11 of the sipe, the radial surface 12 of the sipe, the first tangential surface 13 of the sipe and the second tangential surface 14 of the sipe are respectively connected with the The tool holder axial surface 21, the tool holder radial surface 22, th...

Embodiment 3

[0067] like Figure 16 and Figure 17As shown, embodiment 3 of the present invention provides a kind of high-speed milling cutter, comprises: cutter body 1, and described cutter body 1 is disc-shaped cutter body, and described cutter body 1 is uniformly provided with a plurality of sipes 1a, so The sipe 1a is used to install the cutting unit; the cutting unit includes a tool holder 2, a driving screw 3 and an auxiliary compression screw 4; each of the sipe 1a is composed of a sipe axial surface 11, a sipe radial surface 12. The first tangential surface 13 of the knife groove and the second tangential surface 14 of the knife groove are formed. To the surface 23 and the second tangential surface 24 of the knife holder; the axial surface 11 of the sipe, the radial surface 12 of the sipe, the first tangential surface 13 of the sipe and the second tangential surface 14 of the sipe are respectively connected with the The tool holder axial surface 21, the tool holder radial surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com