Magnetized low-temperature cracking device with water-gas separation device

A low-temperature cracking and separation device technology, which is applied to the discharge device, separation method, and separation of dispersed particles of retort gas, and can solve problems affecting the effect of flue gas purification and treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

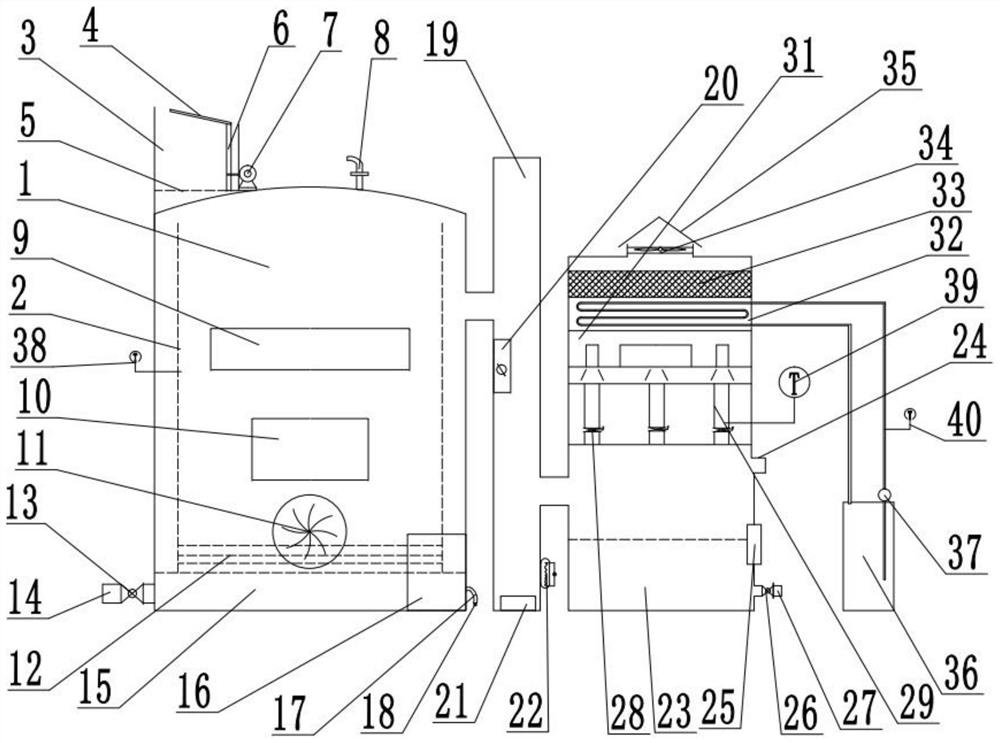

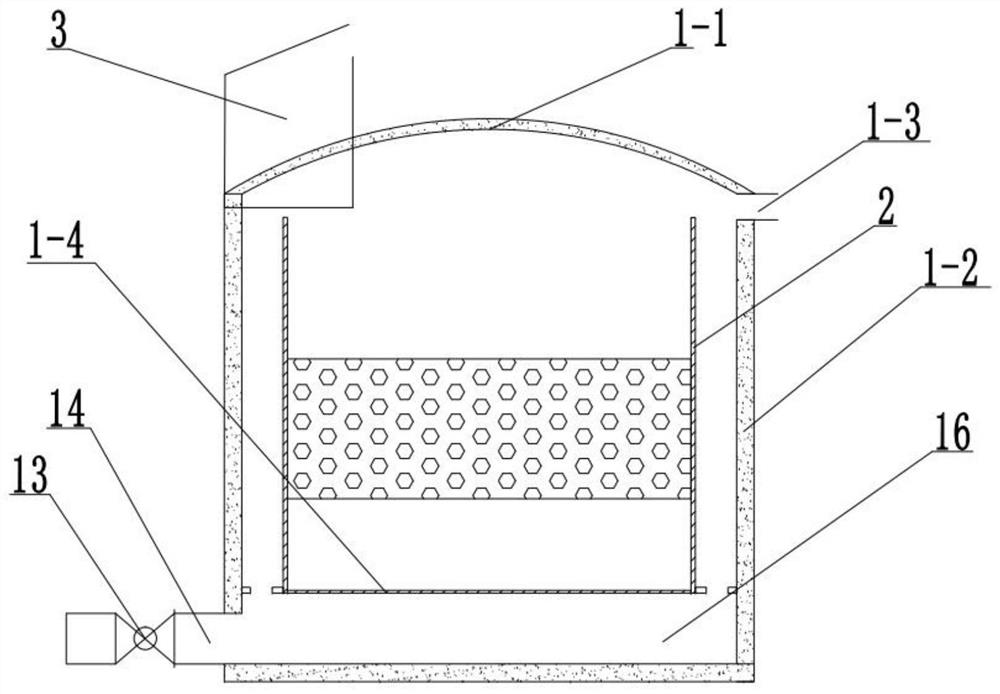

[0022] Combine below Figure 1-2 Description of this embodiment, a magnetized low-temperature pyrolysis device with a water and gas separation device, including a pyrolysis chamber 1, an inner wall of the pyrolysis chamber 2, an explosion-proof valve 8, a surrounding layer containing magnetic ash 9, an observation process port 10, and turbine ash Outlet 11, the inner wall 2 of the cracking chamber is fixedly connected to the inside of the cracking chamber 1, the explosion-proof valve 8 is arranged at the upper end of the cracking chamber 1, and there are multiple surrounding layers 9 containing magnetic ash, and the surrounding layers 9 containing magnetic ash are all fixed. Connected to the cracking chamber 1, the observation process port 10 is set on the cracking cavity 1, and the turbine ash outlet 11 is set on the cracking cavity 1, and it is characterized in that: the cracking cavity 1 includes a vault 1 of the cracking cavity -1, cracking chamber outer wall 1-2, flue gas...

specific Embodiment approach 2

[0025] Combine below Figure 1-2 To illustrate this embodiment, the smoke-free leakage double-door feed transition bin 3, the upper sealing cover plate 4, the bottom sealing cover plate 5, the screw 6 and the drive motor 7, the smoke-free leakage double-door feed transition bin 3 are fixed Connected to the upper end of the cracking chamber 1, the upper sealing cover 4 is rotatably connected to the upper end of the screw 6, the screw 6 is fixedly connected to the output shaft of the driving motor 7, and the bottom sealing cover 5 is fixedly connected to the smoke-free leakage double-door inlet The lower end of the material transition chamber 3, the bottom sealing cover plate 5 is fixedly connected to the upper end of the cracking chamber 1, and the screw rod 6 is rotatably connected to the right end of the smoke-free leakage double-door feed transition chamber 3;

[0026] Turn the upper sealing cover 4, and then start the adjustment motor 7, so that the screw 6 drives the upper...

specific Embodiment approach 3

[0028] Combine below Figure 1-2 Describe the present embodiment, described fire grate 12, sewage outlet valve 13, sewage outlet 14, sewage collecting box 15, magnetized air generating box 16, air inlet pipe 17 and air inlet pipe valve 18, fire grate 12 are fixedly connected in the furnace The lower end of the grate protection plate 1-4, the sewage outlet 14 is fixedly connected to the bottom of the sewage collection box 15, the sewage outlet valve 13 is arranged on the sewage outlet 14, the sewage collection box 15 is fixedly connected to the lower end of the cracking chamber 1, the air inlet pipe 17 is fixedly connected to the magnetized air generating box 16, the air intake pipe 17 is provided with an intake pipe valve 18, the magnetized air generating box 16 is fixedly connected to the lower end of the cracking chamber 1, and the magnetized air generating box 16 is fixedly connected to the sewage collection box 15 on;

[0029]Open the air intake pipe valve 18, the air int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com