Processing method for hydrogenation of catalytically cracked gasoline and reduction of octane number loss

A technology of catalytic cracking gasoline and its processing method, which is applied in the processing field of hydrogenation of catalytic cracking gasoline and reduction of octane number loss, which can solve the problems of large olefin loss and large loss, and achieve the effect of meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

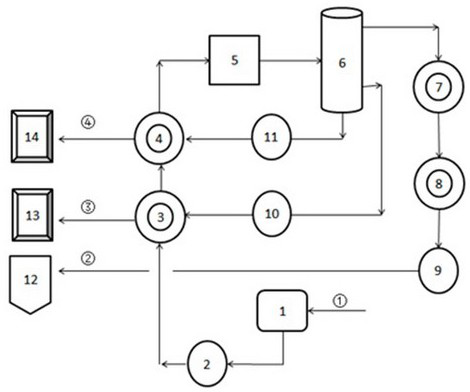

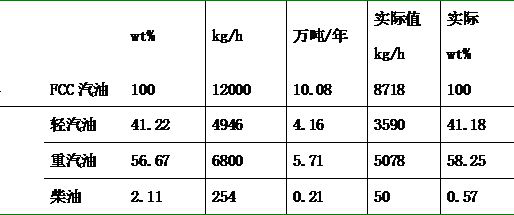

[0048] A kind of catalytic cracking gasoline hydrogenation and the processing method that reduces octane number loss, the inventive method newly builds a set of 100,000 tons / year FCC gasoline sulfur transfer-hydrodesulfurization process test device, such as figure 1 As shown, there are the following steps:

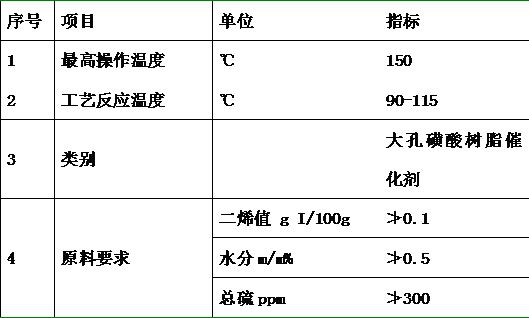

[0049] Catalytic cracking gasoline hydrogenation unit: FCC gasoline enters the buffer tank 1 from the boundary area, and is heated to After 90°C, it enters pre-hydrogenation reactor 5, and the diene in the raw material in 5 is saturated, and the diene value g I / 100g≯0.1;

[0050]Catalytic reaction rectification unit: gasoline after pre-hydrogenation enters the catalytic reaction rectification tower 6, and the catalyst adopts the alkylation sulfur transfer catalyst GST-1 developed by the Research Institute of PetroChina Urumqi Petrochemical Branch (composition and physical and chemical indicators: macroporous sulfur Acid resin catalyst, the main component is a polymer of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com