Wall surface metal plate assembly type installation structure with energy storage function and construction method thereof

A metal plate and assembly technology, which is applied in the field of architectural decorative panels to achieve the effects of reducing labor costs, good heat preservation, and improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

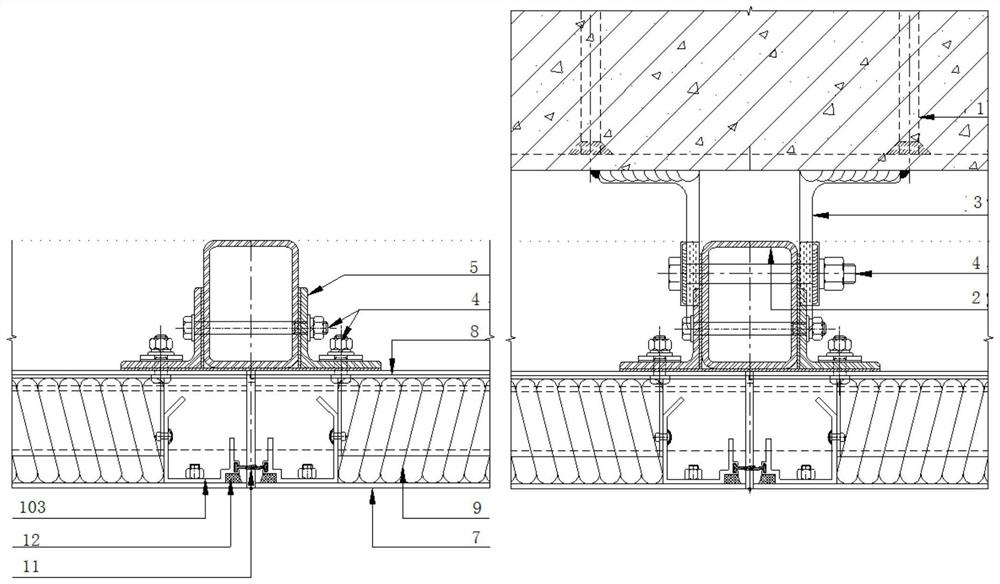

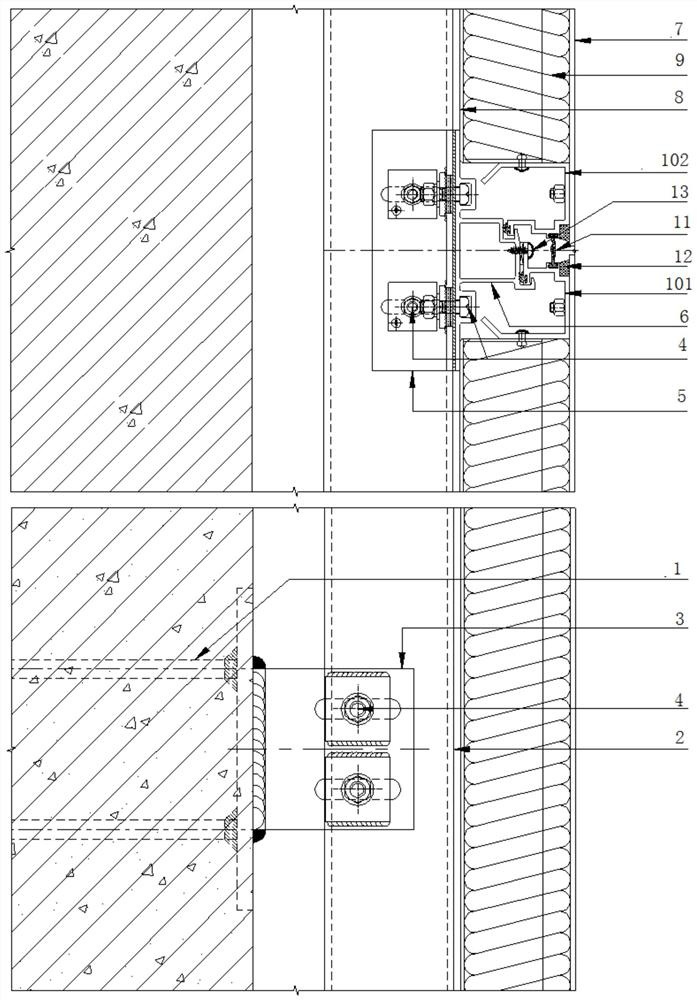

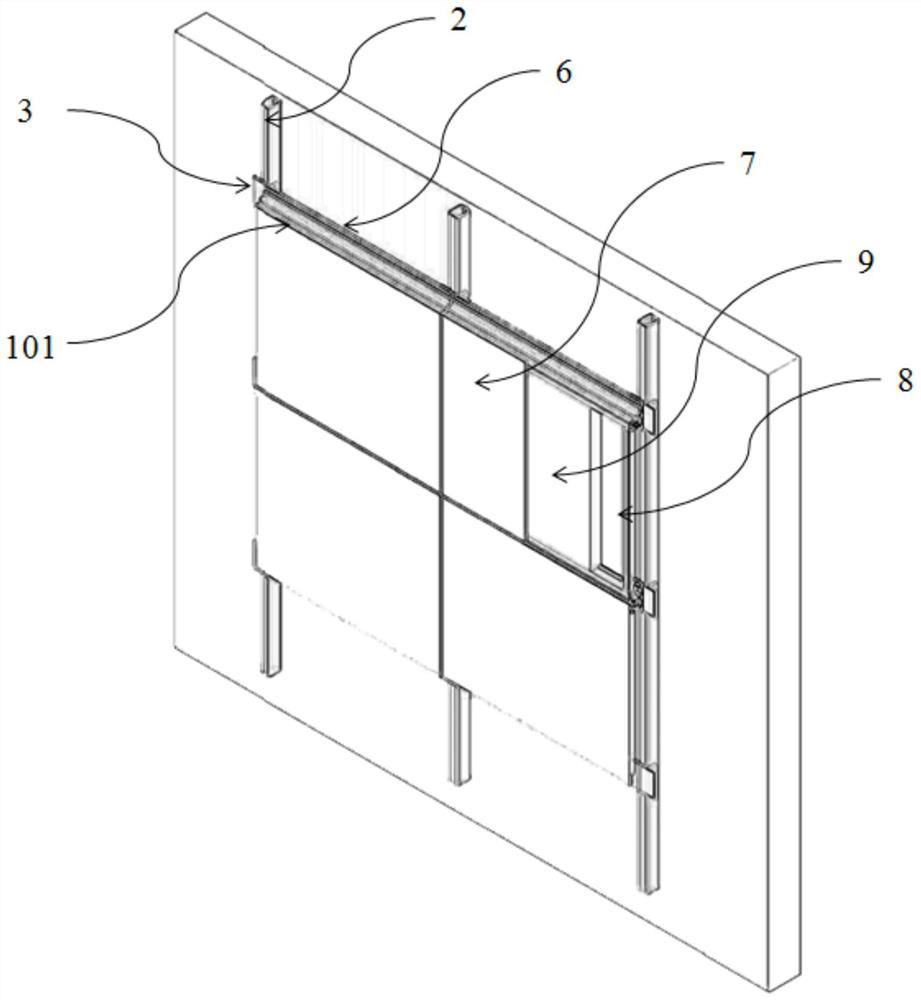

[0037] The present invention will be further described below in conjunction with the accompanying drawings.

[0038] The wall metal plate assembly installation structure with energy storage function mainly includes: embedded parts 1, metal columns 2, metal corner codes 3, metal connectors 5, metal beams 6, metal decorative panels 7, metal back panels 8, Honeycomb structure 9, metal sub-frame 10;

[0039] combine figure 1 , 2, 3, the embedded part 1 is installed in the wall, and the exposed part is welded with the metal corner bracket 3; preferably, the installation position of the metal corner bracket 3 is an oblong hole structure, which can facilitate the horizontal adjustment of the column when the metal column 2 is installed In and out positions; toothed gaskets are also installed on both sides of the bolt 4 to prevent loosening and prevent the structure from falling. The metal column 2 is fixedly connected with the metal corner bracket 3 through the bolt 4 . The metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com