On-line hot standby method for fan unit of ethylene cracking furnace

An ethylene cracking furnace and cracking furnace technology, applied to pump devices, mechanical equipment, components of pumping devices for elastic fluids, etc., can solve problems affecting the production efficiency of the ethylene cracking furnace and affecting the normal operation of the ethylene cracking furnace, etc. It achieves the effect of convenient daily maintenance and hidden danger investigation, simple and reliable structure, and quick replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

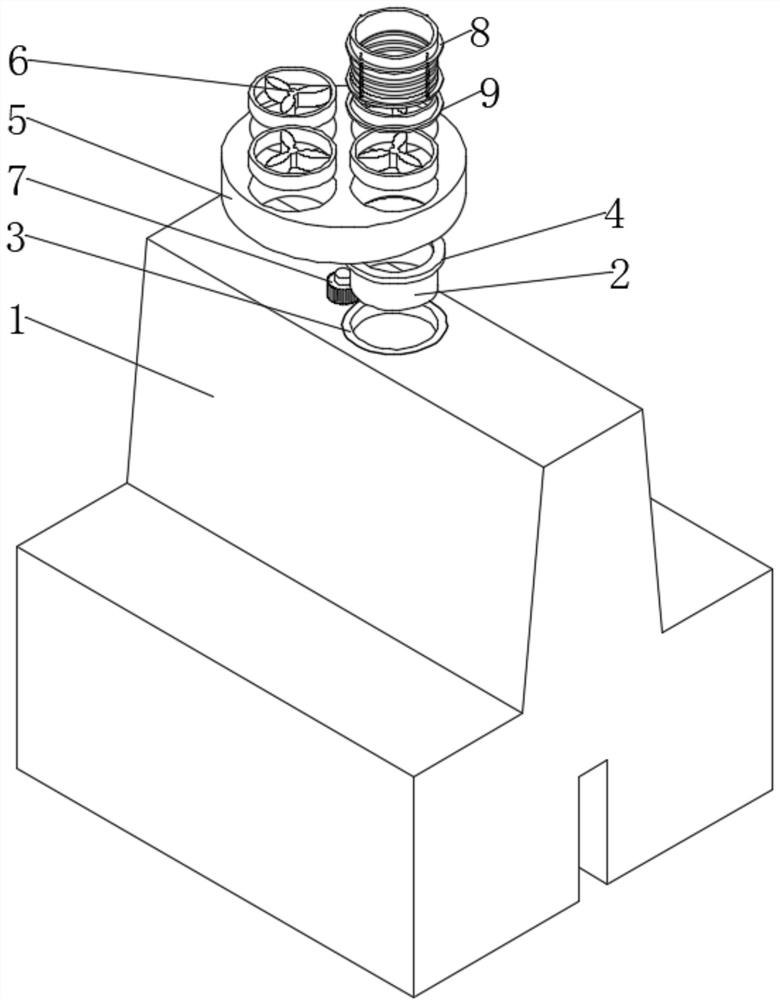

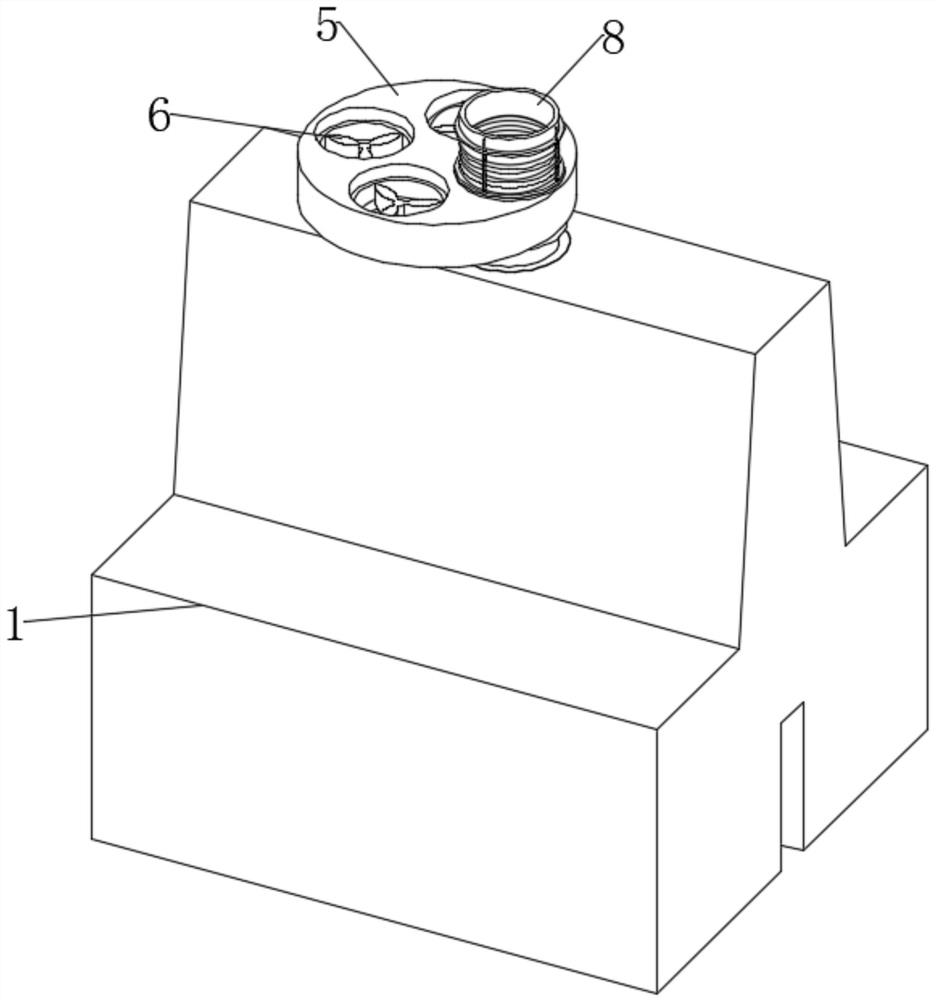

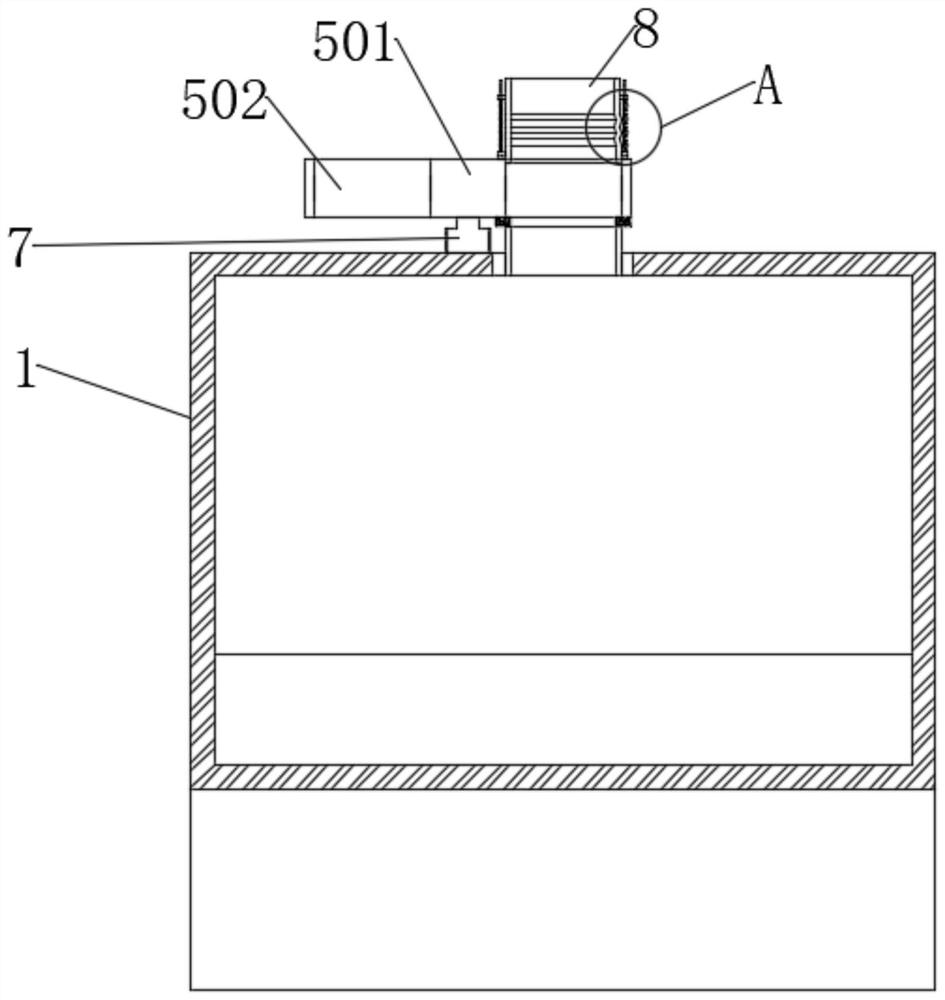

[0037] An online hot standby method for an ethylene cracking furnace fan unit, the main steps of which include:

[0038]S1. Fan monitoring. The fan for ventilation of the ethylene cracking furnace is set as a working position fan, and the sensor loaded in the fan is used to monitor the working position fan speed and working temperature in real time. The sensor settings and monitoring methods are based on this The well-known technology of those skilled in the art, so it is not described in detail in this application, those skilled in the art can easily complete the setting and use of the sensor according to the existing technology in the field;

[0039] S2. Fan replacement. When the working time of the fan reaches the preset standard or the speed of the fan fails to reach the preset standard for a long time, the fan at the working position is replaced while the ethylene cracking furnace is not shutting down as a whole, and technicians are arranged to repair the fan from the fan....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com