Silo stacking height monitoring device, system and method

A monitoring device and stockpiling technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of poor measurement stability and high material characteristics requirements, and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] When storing in silos, in order to monitor the inventory and changes of materials in the silo in real time and automatically, it is necessary to use an automatic sensing device to measure the height of the materials. Due to the different physical and chemical properties of materials such as moisture content, composition, shape, and electrical conductivity, some commonly used automatic sensing devices cannot accurately and stably measure the height of materials. This embodiment provides a stacking height measuring device for silo storage, which can automatically, quickly, accurately and stably obtain the stacking heights of different materials in the silo.

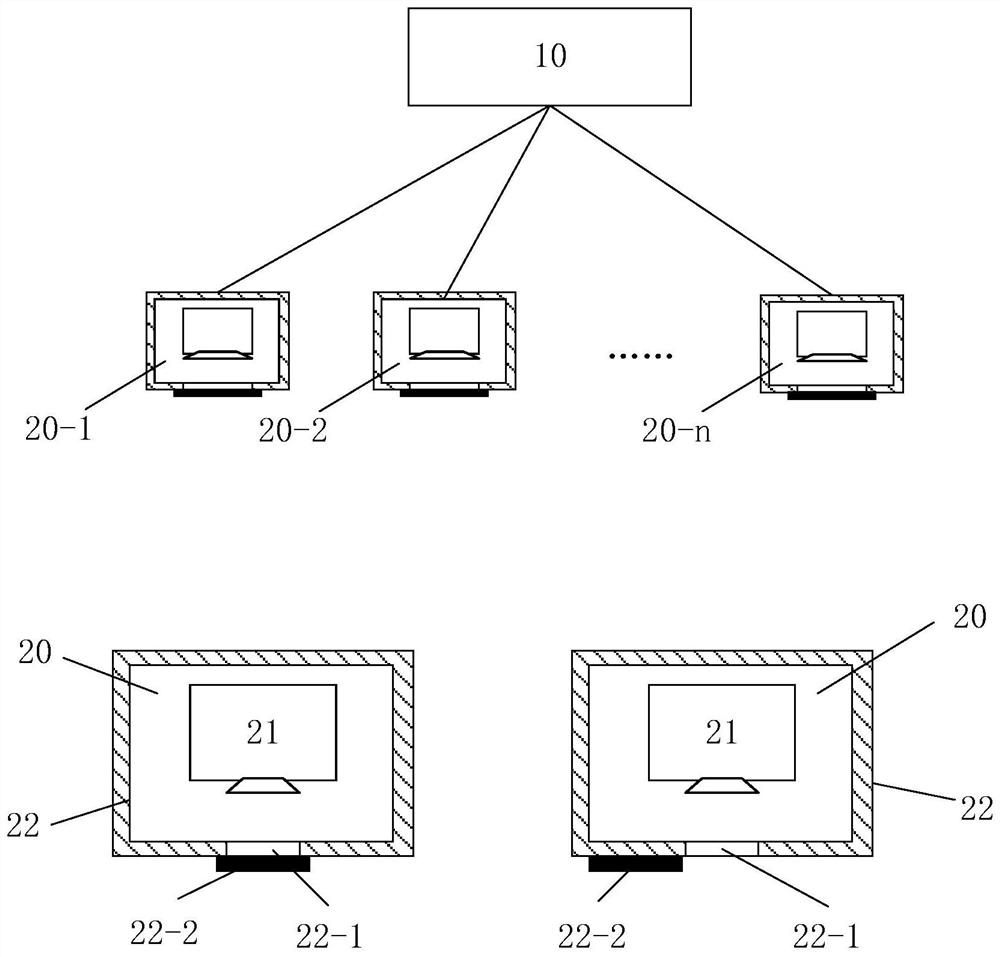

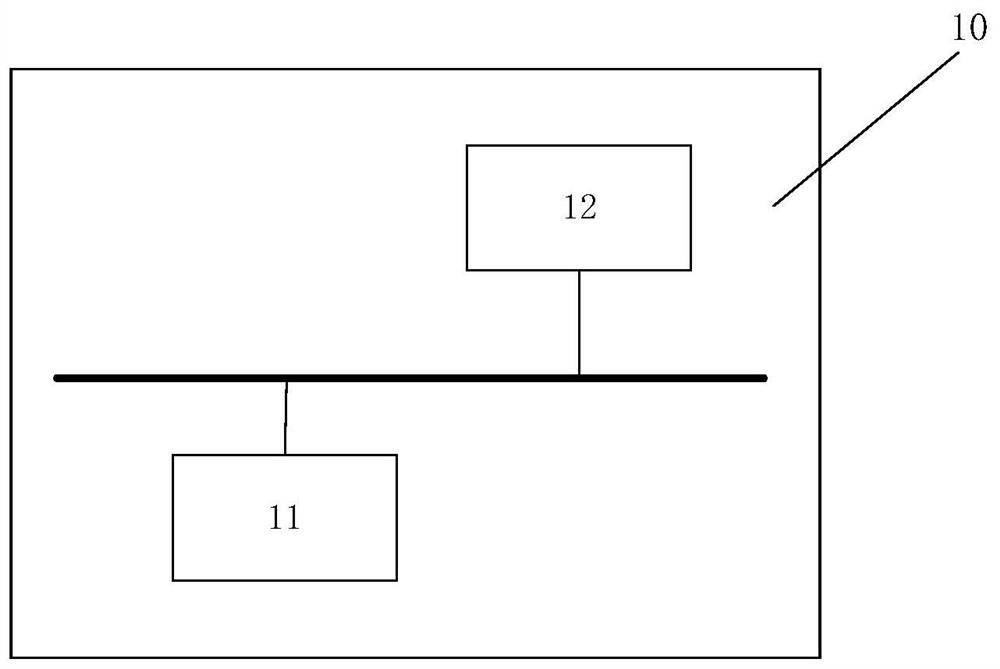

[0038] Combine below figure 1 Describe the specific structure of the device for monitoring the silo stocking height provided by this embodiment:

[0039]The device for monitoring the stocking height of a silo includes at least one data processing module 10 and at least one group of monitoring modules 20 . The monit...

Embodiment 2

[0057] On the basis of the device for monitoring the height of silo stockpiling provided in the above-mentioned embodiment 1, the present invention can also integrate the device for monitoring stockpiling height of silos into the overall silo storage system to provide a monitoring device for stockpiling height of silos system.

[0058] Such as Figure 7 As shown, it is a schematic structural diagram of a system for monitoring the height of silo stockpiling provided by this embodiment.

[0059] The system includes a monitoring device 1, a monitoring control device 2 and a silo 3 designed according to the device design of the silo stacking height monitoring proposed in embodiment 1;

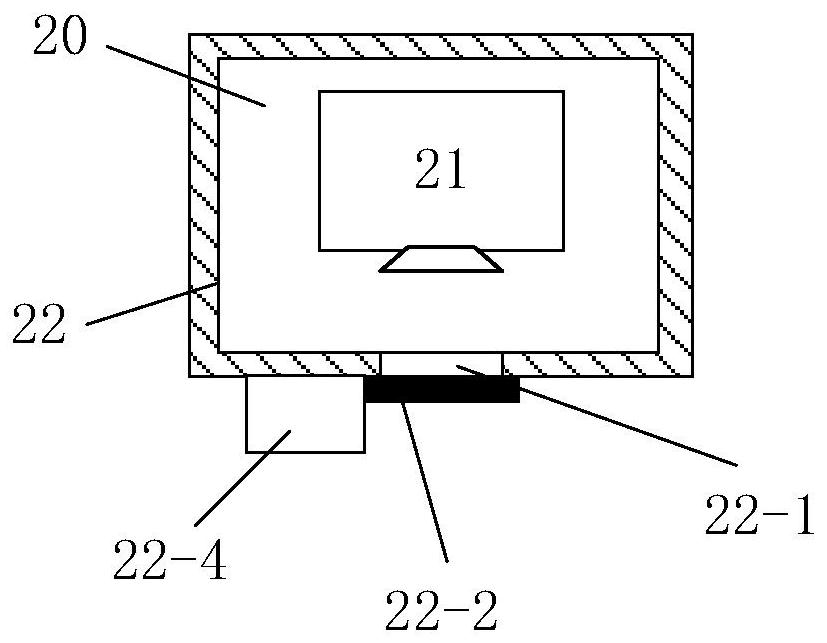

[0060] The monitoring module 20 in the monitoring device 1 is arranged on the top of the silo 3 , and the light-transmitting window 22 - 1 of the monitoring module 20 faces the top surface of the stacked material in the silo 3 . Since the light transmission window 22-1 corresponds to the monitori...

Embodiment 3

[0067] On the basis of the device for monitoring the height of silo stockpiling provided in the above-mentioned embodiment 1 and the system for monitoring the height of stockpiling in silos provided in embodiment 2, the present invention provides a system for monitoring the height of stockpiling in silos. A method for monitoring the stacking height in the warehouse.

[0068] Those of ordinary skill in the art can understand that all or part of the steps in the process of each step of embodiment 3 can be completed by the relevant hardware in the system for instructing the silo stacking height monitoring system through the program, and the steps in embodiment 3 can be stored In the readable storage medium that exists in each equipment of monitoring device 1 and monitoring control device 2 in the system of silo stacking height monitoring, storage medium can comprise: read-only memory (ROM, Read Only Memory), random access memory (RAM, Random Access Memory), disk or CD, etc.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com