Aluminum alloy substrate for magnetic disk, disk drive device, method for manufacturing aluminum alloy substrate for magnetic disk, and method for measuring aluminum alloy substrate for magnetic disk

A technology of aluminum alloy substrate and manufacturing method, which is applied in the manufacture of base layer, record carrier manufacture, magnetic recording, etc., and can solve the problems of poor floating stability of magnetic head, influence of floating stability of magnetic head, vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~2 and comparative example 1~2

[0095] First, it is heated and melted according to a conventional method to prepare a material containing Mg: 3.8% by mass, Cu: 0.02% by mass, Zn: 0.3% by mass, Cr: 0.05% by mass, Si: 0.01% by mass, Fe: 0.01% by mass, and The remainder is an aluminum alloy melt composed of aluminum and unavoidable impurities. Next, an aluminum alloy is cast from the prepared aluminum alloy melt at a cooling rate of 1.0° C. / s by a semi-continuous casting (DC) method. Next, after 10 mm surface cutting of the aluminum alloy ingot, homogenization treatment was performed at 530° C. for 3 hours, hot rolling was performed at a starting temperature of 450° C., and cold rolling was performed at a rolling rate of 57%. Rolling to manufacture aluminum alloy plates. Then, the aluminum alloy plate was punched into an annular shape to produce an aluminum alloy substrate for a magnetic disk as a disk blank.

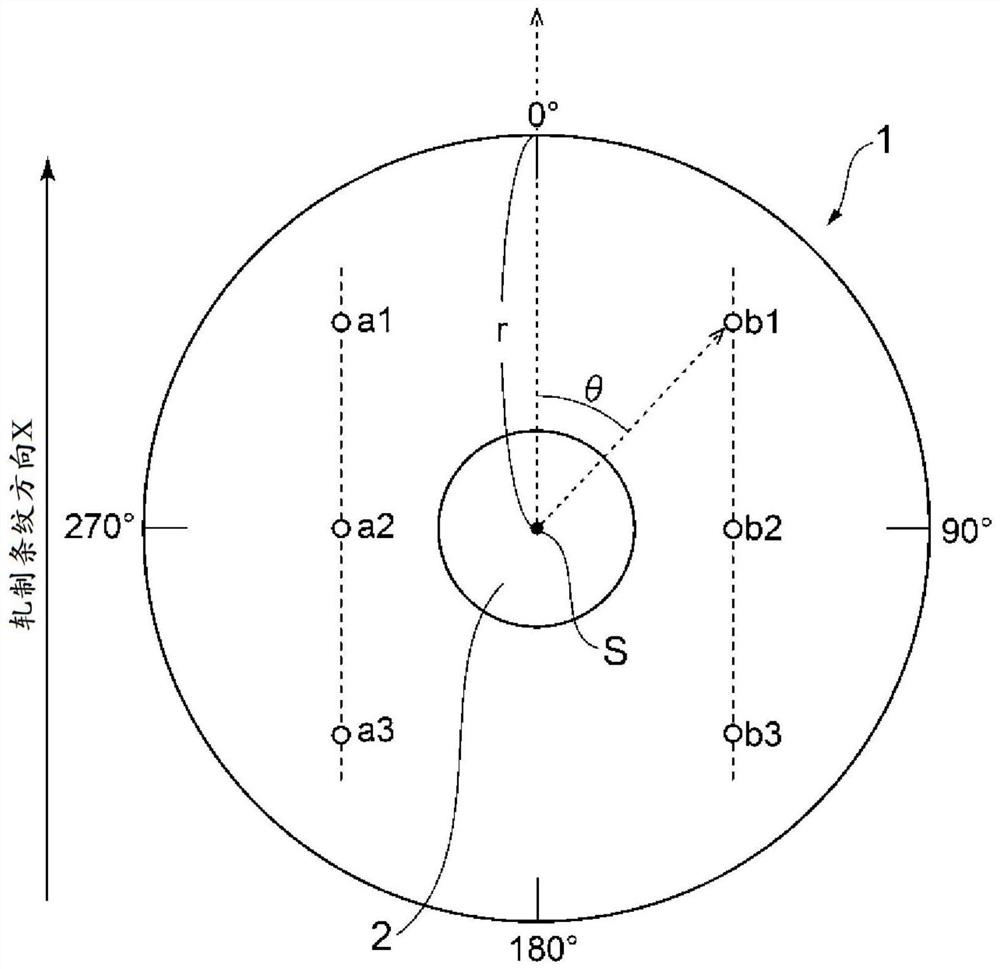

[0096] Next, prepare Figure 5 In the plate thickness measuring device shown in , the aluminum allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com