Industrial workshop dust adsorption treatment system

A technology for adsorption treatment and dust, which is applied in the direction of dispersion particle separation, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of decreased adsorption capacity, reduced humidity, and the impact on the health of staff, so as to improve adsorption capacity, Effect of increasing humidity and maintaining dust adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

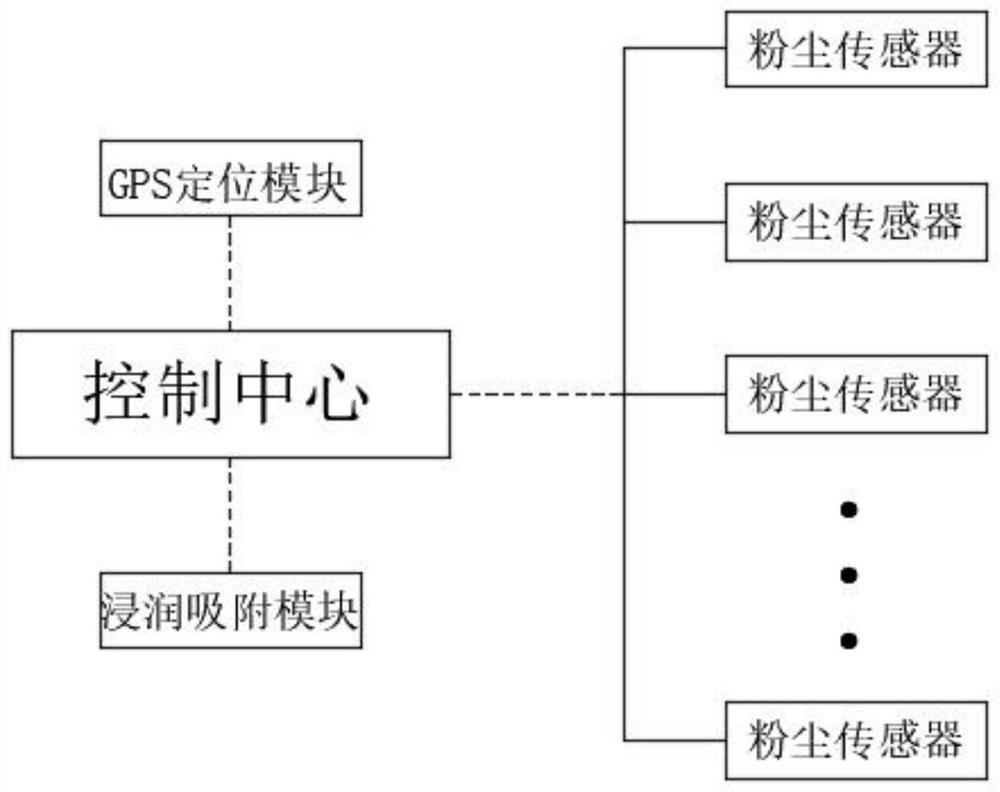

[0045] see figure 1 , an industrial workshop dust adsorption treatment system, including a control center, a GPS positioning module, a dust detection module, and an infiltration adsorption module. Dust sensor, a plurality of dust sensors are connected with GPS positioning module signal.

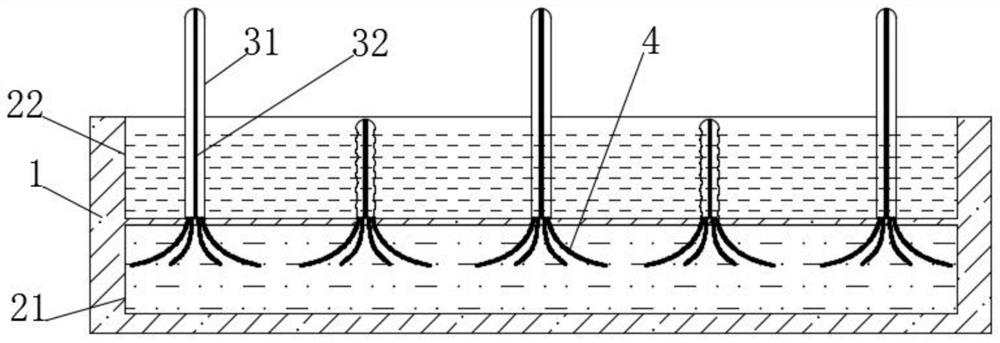

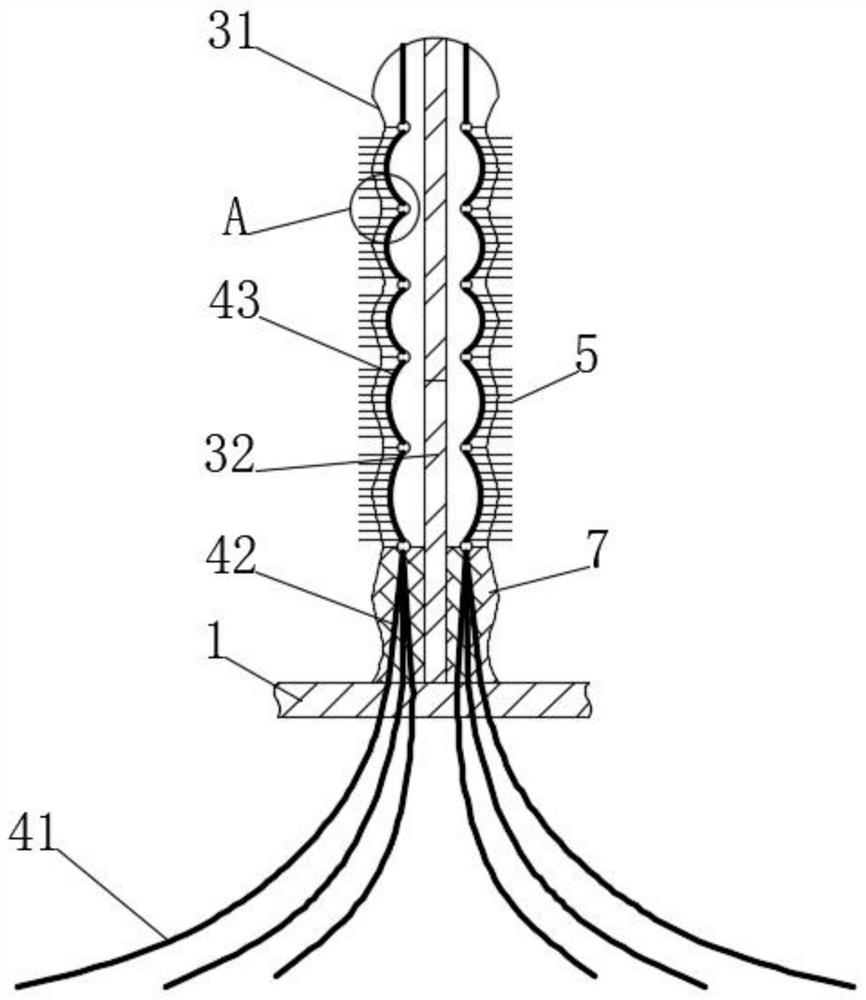

[0046] see figure 2 , the infiltration adsorption module includes an adsorption frame 1, and the upper end of the adsorption frame 1 includes and distributes an outer infiltration tank 22 and an inner water replenishment chamber 21 respectively. A plurality of infiltration and adsorption rods are provided, and the infiltration and adsorption rod includes a shrinkage adsorption layer 31 fixedly connected to the inner bottom of the outer infiltration tank 22 and an electric push rod 32, the electric push rod 32 is located inside the shrinkage adsorption layer 31, and the electric push rod The upper end of 32 is fixedly connected with the inner top end of the shrinkage adsorption layer 31, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com