A Quantitatively Controlled Atomization Cooling Device

A quantitative control and atomization cooling technology, which is applied in the field of casting manufacturing cooling, can solve problems such as uneven atomization and easy generation of liquid accumulation, achieve good fogging effect, increase air flow disturbance, and ensure the surface quality of slabs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

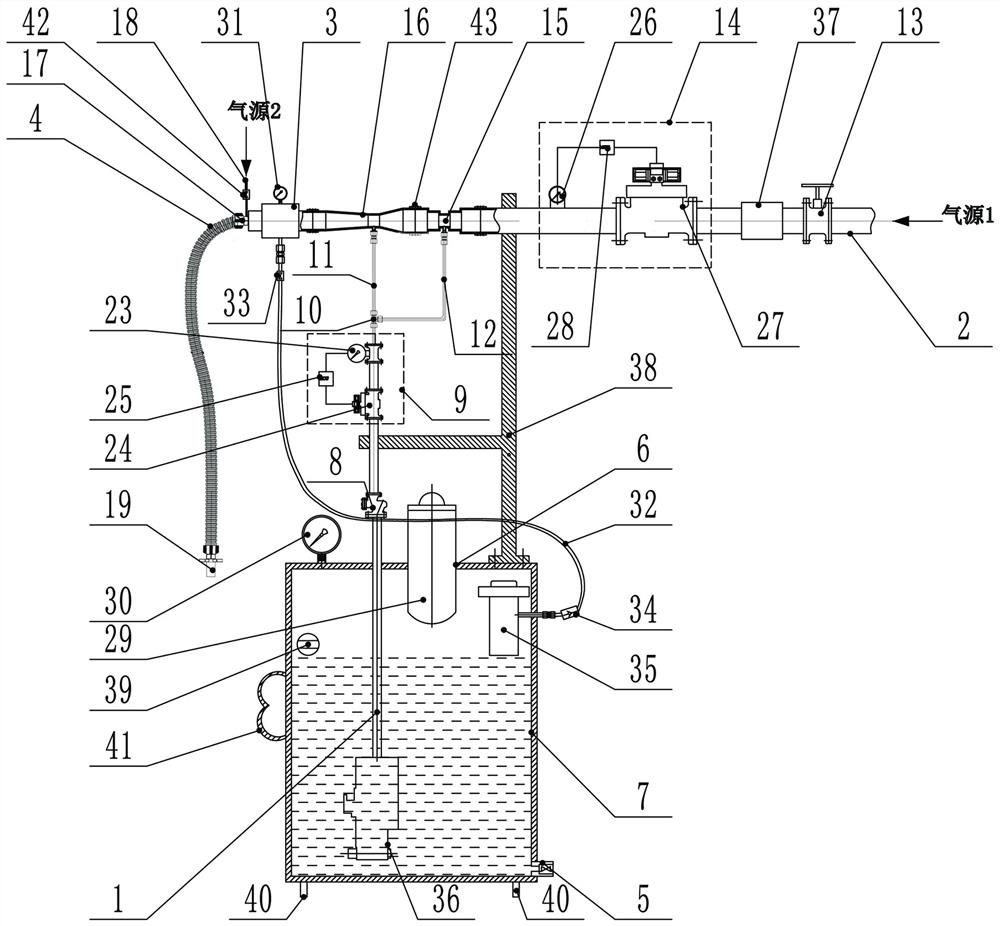

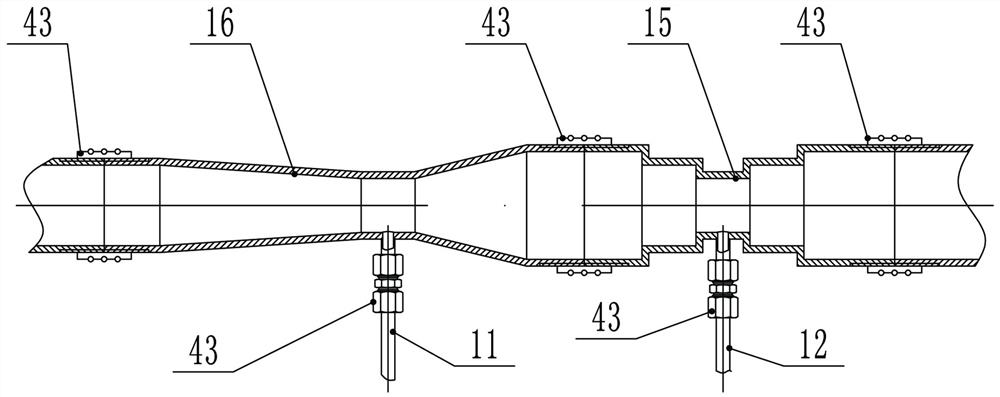

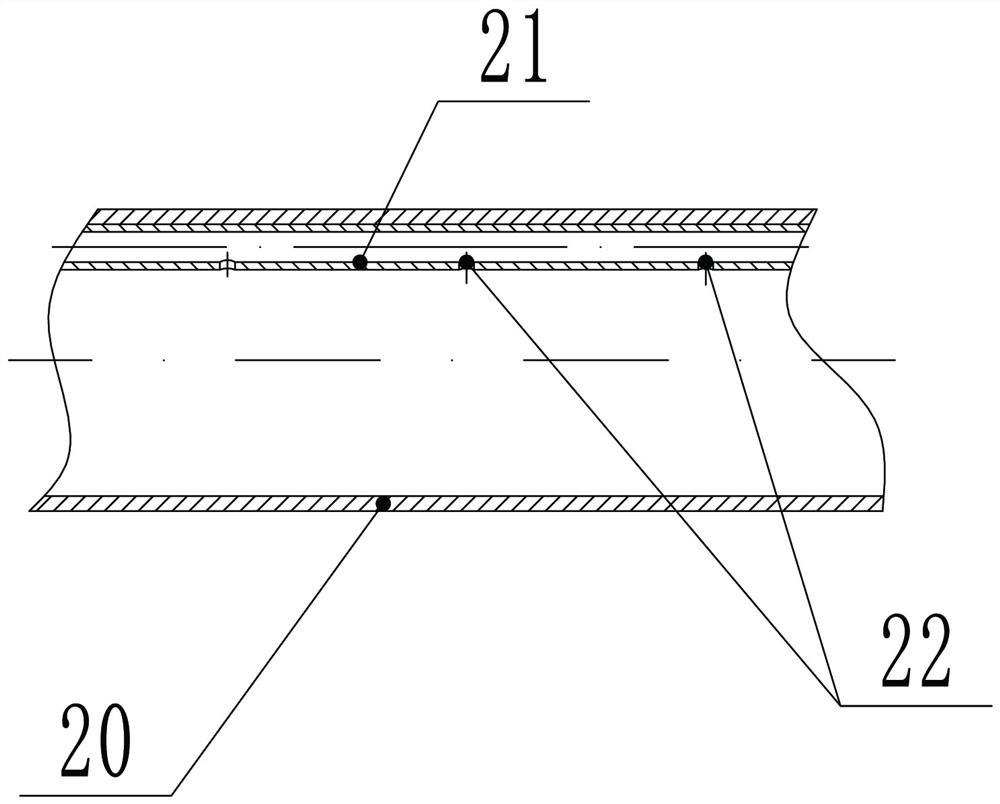

[0022] refer to figure 1 , figure 2 with image 3 , a quantitative control atomization cooling device described in the present invention will be described in detail.

[0023]A quantitatively controlled atomization cooling device, comprising a liquid delivery pipeline 1, a gas delivery pipeline 2, an atomization chamber 3, a double set of joint hoses 4, and a closed box 7 with a cooling liquid inlet and outlet 5 and a vent 6, One end of the liquid delivery pipeline 1 extends into the bottom of the airtight box 7, and the other end of the liquid delivery pipeline 1 passes through the check valve 8 and the cooling liquid quantitative control unit 9 successively and is connected with a first three-way joint 10, the first three-way joint The other two ends of 10 are respectively connected with a first pipeline 11 and a second pipeline 12; the gas delivery pipeline 2 is sequentially connected with a first stop valve 13 and a gas quantitative control unit 14 along the gas flow dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com