Camber-variable wing trailing edge and wing

A wing leading edge, wing technology, applied in wing adjustment, non-power amplification, aircraft transmission, etc., can solve the problem of destroying the continuity of the wing surface, reducing the aerodynamic characteristics of the aircraft, and difficult to meet the multi-task flight. Conditions and other issues, to achieve the effect of light weight, simple structure and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

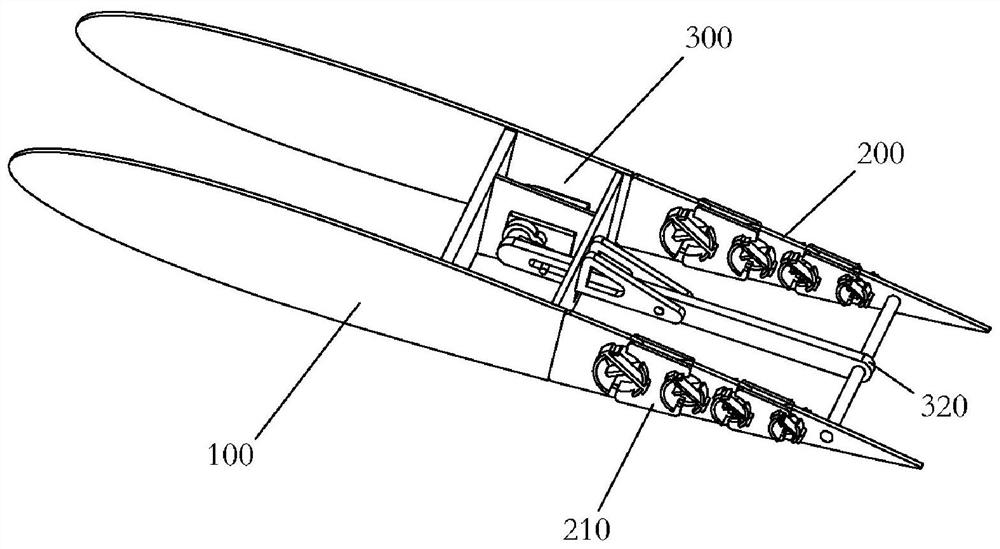

[0032] A variable camber wing, such as Figure 1-6 As shown, it includes a wing leading edge 100 with constant camber, a wing trailing edge 200 with variable camber, and wing skin.

[0033] In this example, the wing skin (not shown) is connected with the leading edge 100 of the wing in a riveted manner. In order to better follow the curvature of the trailing edge 200 of the wing, the skin, to produce adaptive deformation when the trailing edge 200 of the random wing changes curvature.

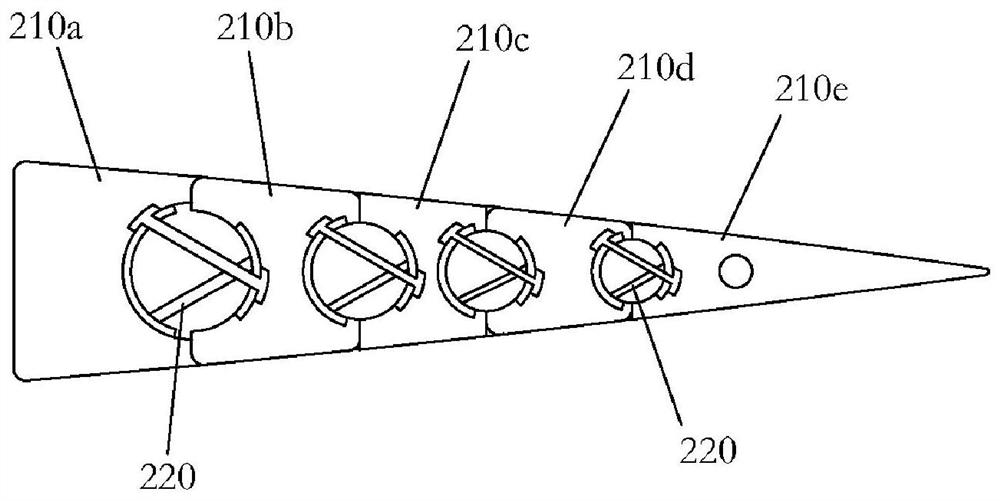

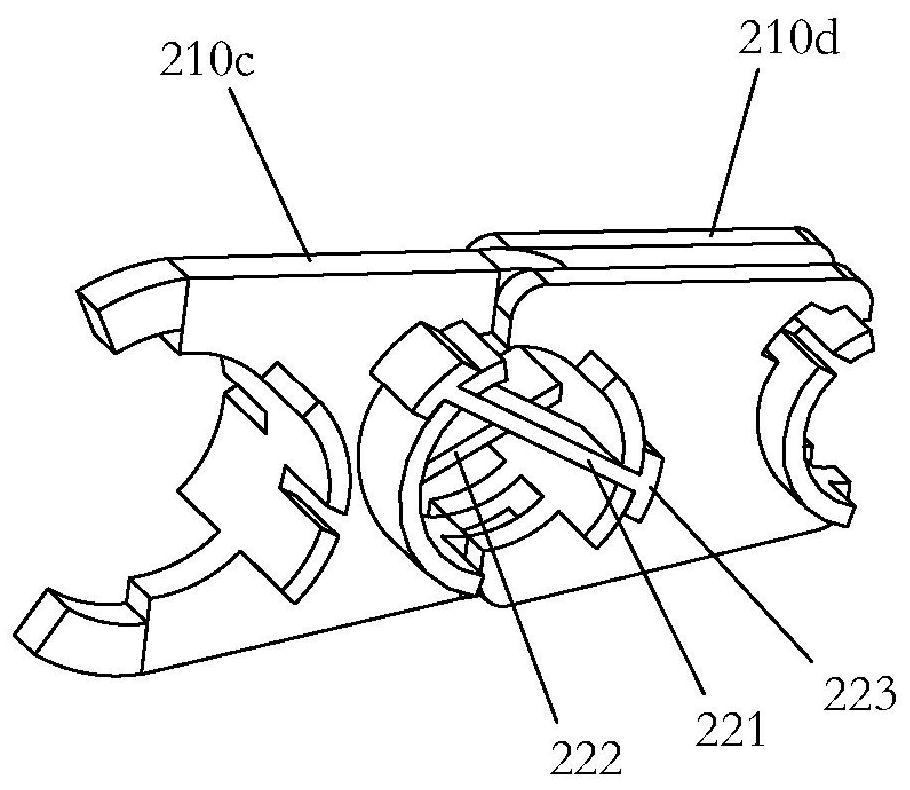

[0034] The trailing edge 200 of the wing includes five sub-ribs 210 connected in sequence, two adjacent sub-ribs 210 are connected by a flexible hinge 220, and the five sub-ribs 210 are driven by the driving device 230 to bend upward or downward. curved, wherein, to accommodate the shape of the wing trailing edge 200, the five sub-ribs 210 are not identical in shape, see figure 1 , figure 2 , are respectively the first sub-rib 210a, the second sub-rib 210b, the third sub-rib 210c, the fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com