Freezing degreasing device for tea oil production and using method thereof

A technology of freezing degreasing and camellia oil, which is applied in the direction of producing fat, fat oil/fat refining, etc. It can solve the problems of laboriousness, poor sealing of joints, and increased labor intensity of staff, so as to reduce labor intensity and improve sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

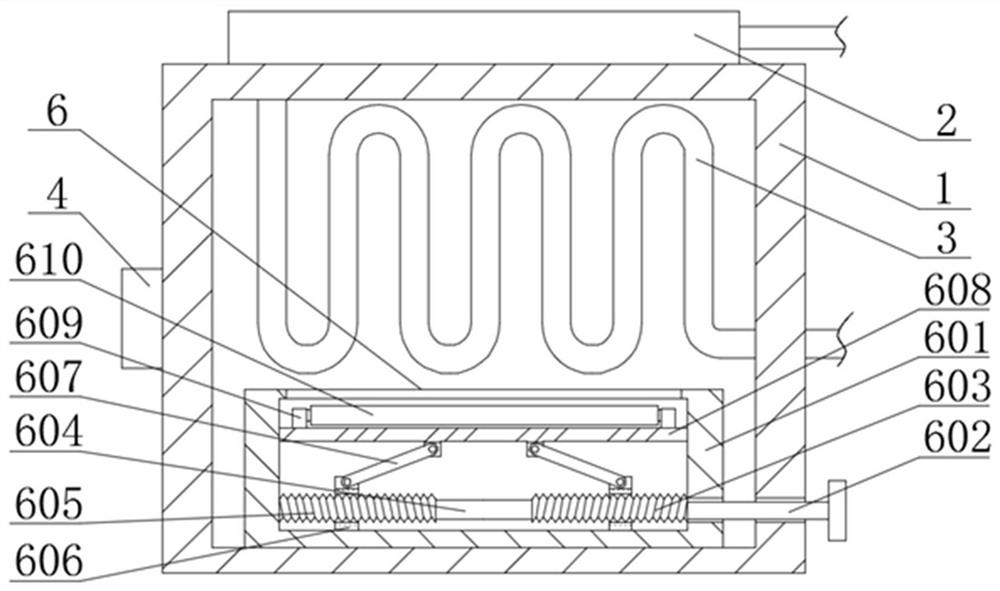

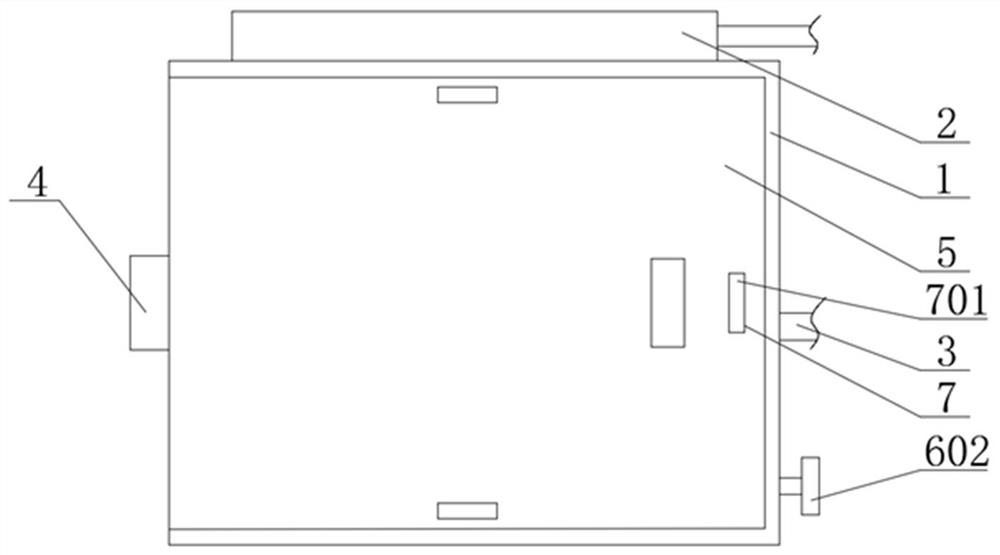

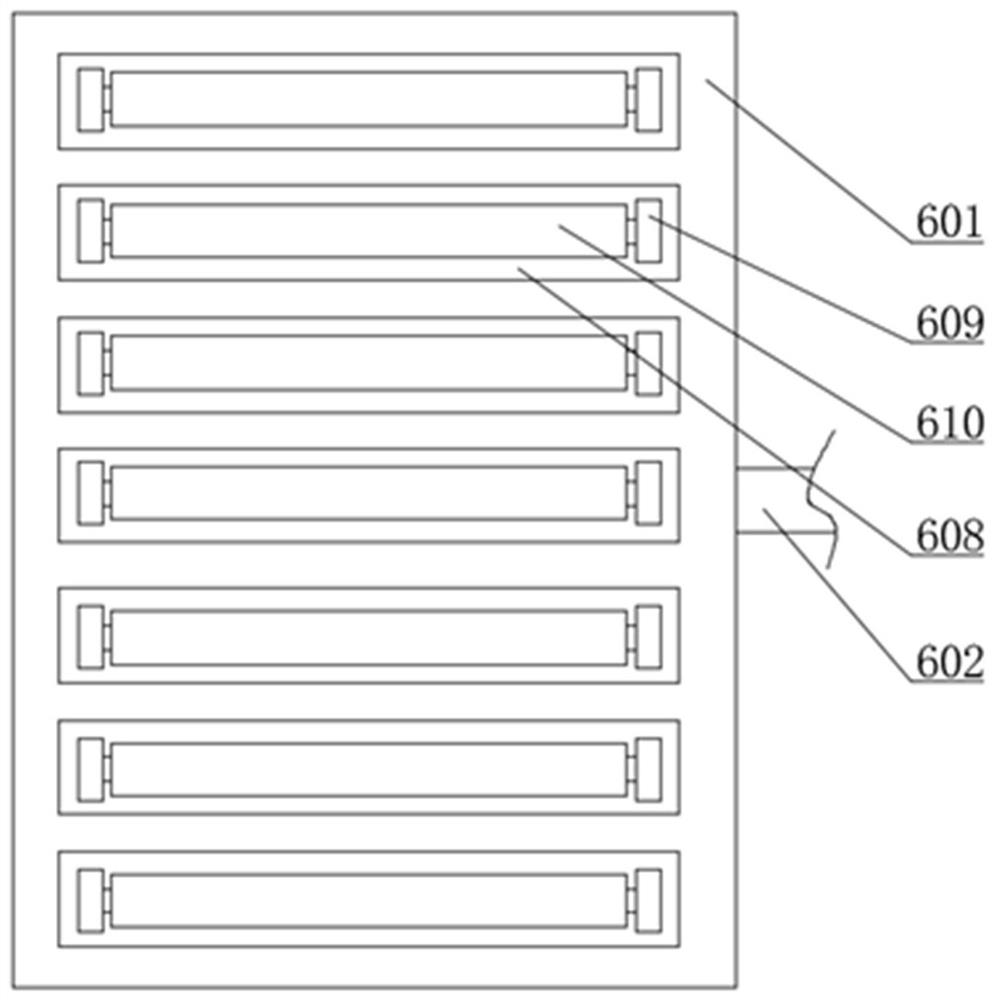

[0024] see Figure 1-5 , the present invention provides a technical solution:

[0025] A freezing degreasing device for camellia oil production and its use method, comprising a freezer 1, a door 5, a moving device 6 and a sealing device 7, the freezer 1 is hingedly connected to the door 5, this setting is convenient for opening the freezer 1, The top surface of the freezer 1 is fixedly connected with a condenser 2, and the outside of the condenser 2 is connected with a condensation pipe 3, which runs through the freezer 1, and the condensation pipe 3 is fixedly connected with the freezer 1. For refrigeration, the controller 4 is fixedly connected to the center of the left end of the freezer 1, and the mobile device 6 includes a bottom plate 601 and a first handle 602. The bottom plate 601 is fixedly connected to the freezer 1, the first handle 602 runs through the bottom plate 601, and the first handle 602 rotates with the bottom plate 601. Connection, the first handle 602 ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com