A low-temperature cleaning agent suitable for fluorine-free refrigeration industry and its preparation method and application

A cleaning agent and industry technology, applied in the field of low-temperature cleaning agent and its preparation, can solve the problems of capillary blockage in refrigeration system, difficulty in rinsing with inorganic salts, harsh working environment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation of antirust additive in the embodiment is as follows:

[0027] Mix 25% of pure water, 35% of isooctanoic acid, and 15% of hydroxyethylethylenediamine at 100°C for 2 hours, then add 15% of triethylenetetramine, mix and react for 2 hours at 100°C, and finally add 10% ethanol, mixed and stirred at room temperature for 1 hour, and the stirring speed was 100 rpm, and the antirust additive was obtained.

Embodiment 1-2

[0029] The preparation method of embodiment 1-2 low temperature cleaning agent is as follows:

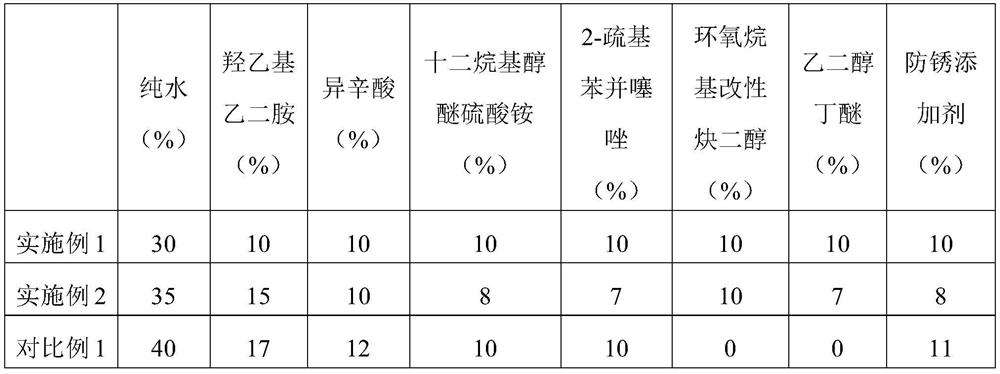

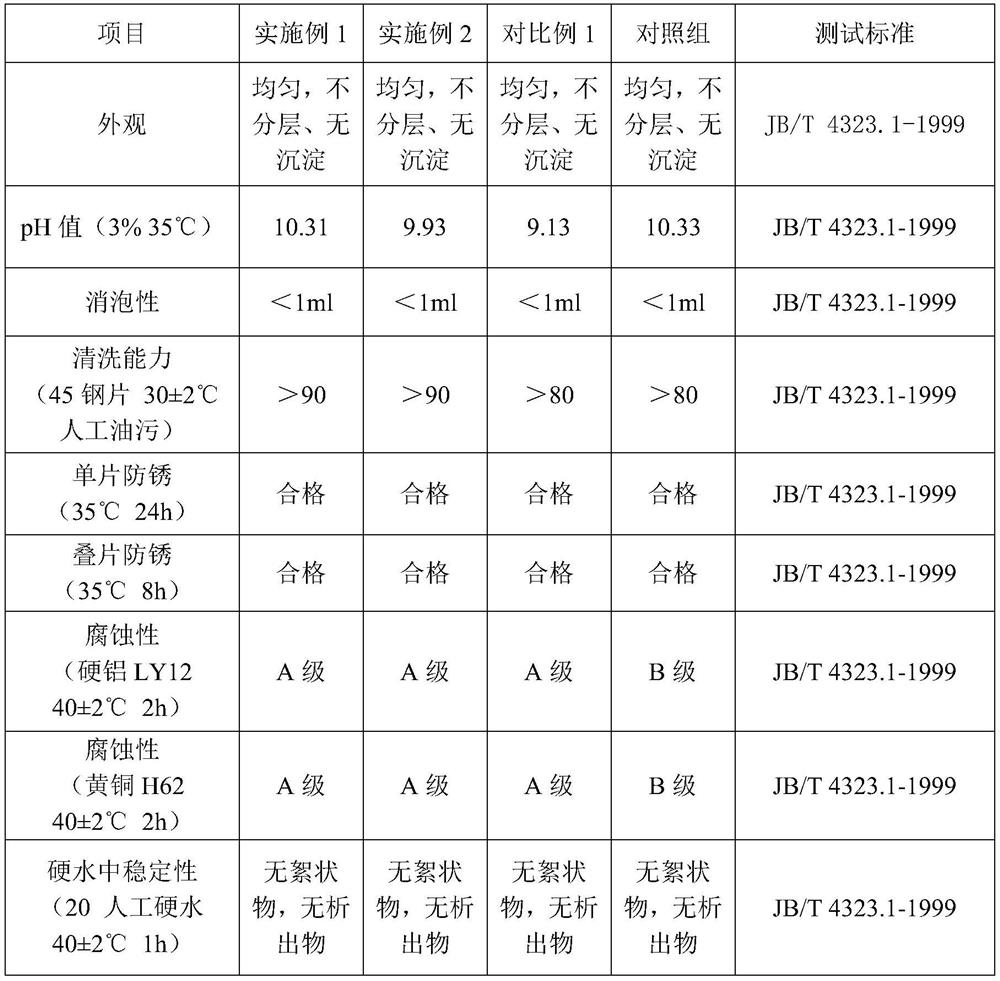

[0030] Mix water and hydroxyethylethylenediamine and stir for 0.5h, then add isooctanoic acid and stir for 0.5h, add ammonium lauryl alcohol ether sulfate and stir for 0.5h, add 2-mercaptobenzothiazole and stir for 0.5h, add cyclic Oxyalkyl modified acetylene glycol was stirred for 0.5 h, ethylene glycol butyl ether was added and stirred for 0.5 h, and antirust additive was finally added and stirred for 2 h to obtain the low-temperature cleaning agent. The stirring speed is 100 rpm. The addition amount of each component is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com