Target feeding mechanism of coating machine

A technology of feeding mechanism and coating machine, applied in coating, metal material coating process, ion implantation coating and other directions, can solve the problems of poor tool coating, hidden safety hazards of explosion, unreasonable structural design, etc. Coating yield, avoid burst effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

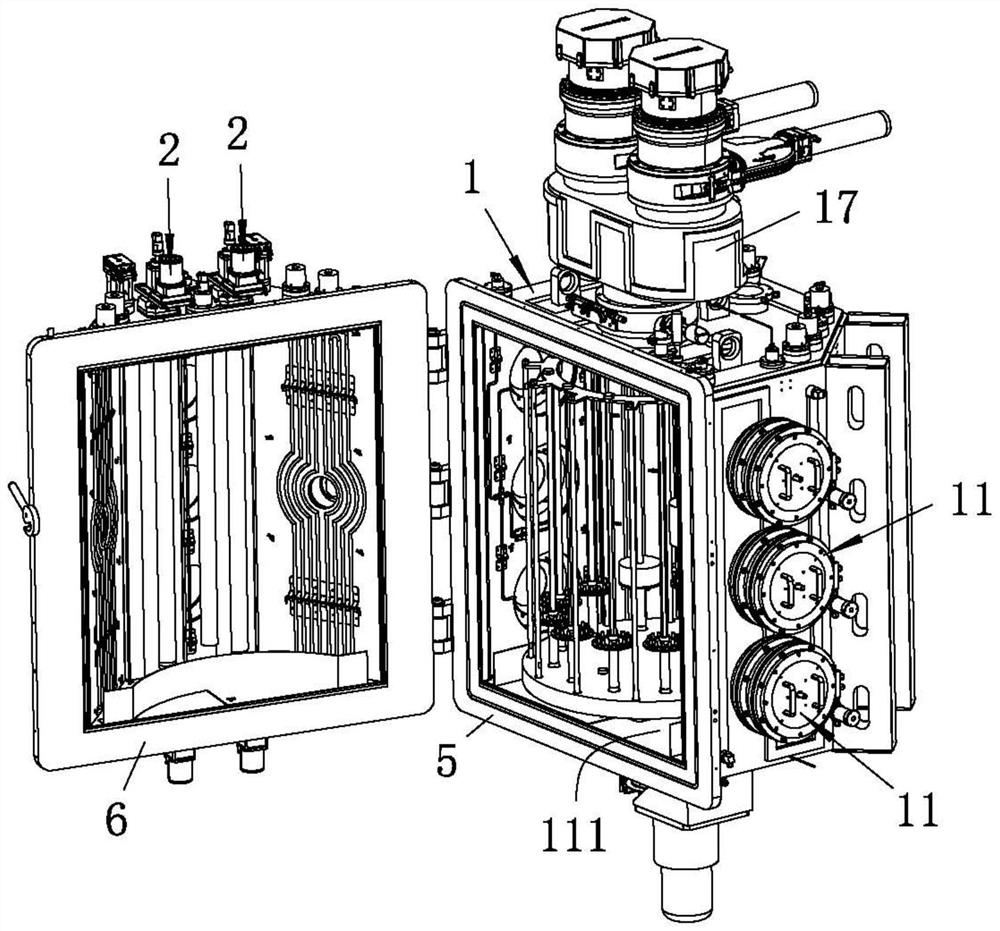

[0030] see Figure 1 to Figure 5 As shown, a target feeding mechanism of a coating machine according to the present invention includes a chassis 1 and a first feeding unit 2 detachably connected to the chassis 1. The chassis 1 is surrounded by a plurality of metal plates. The chassis 1 Roughly in the shape of a hollow cuboid, the cabinet 1 is provided with an accommodating cavity 111 , and the first supply unit 2 is used for evaporating the first target material 211 from the outside into target ions entering the cabinet 1 .

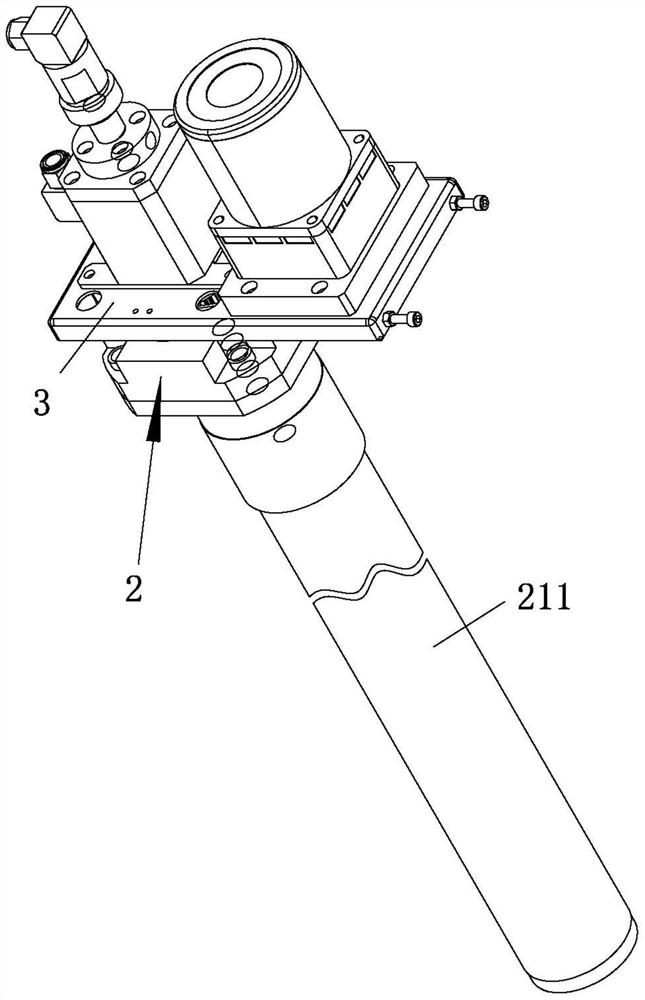

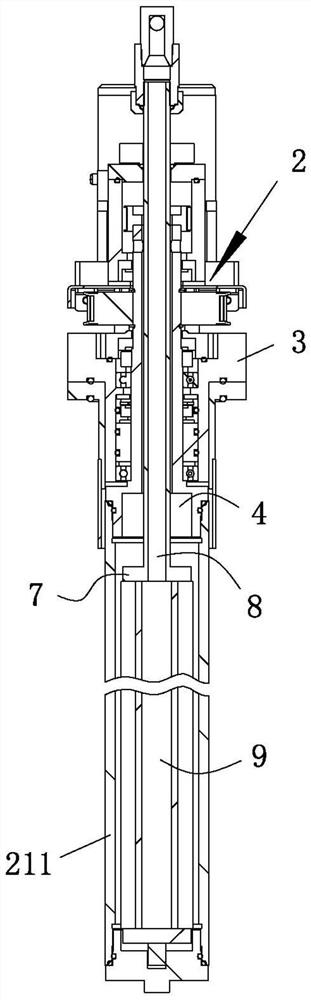

[0031] The first supply unit 2 includes a first carrier 3 that is detachably connected to the cabinet 1 and is used to carry the first target material 211 , an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com