Stripping electroslag furnace, application thereof and ledeburite carbide control method

A technology of electroslag furnace and ledeburite, which is applied in special data processing applications, electrical digital data processing, design optimization/simulation, etc., and can solve problems such as refining the core grains of remelting ingots and internal quality control. , to achieve the effect of avoiding steel breakout and preventing explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

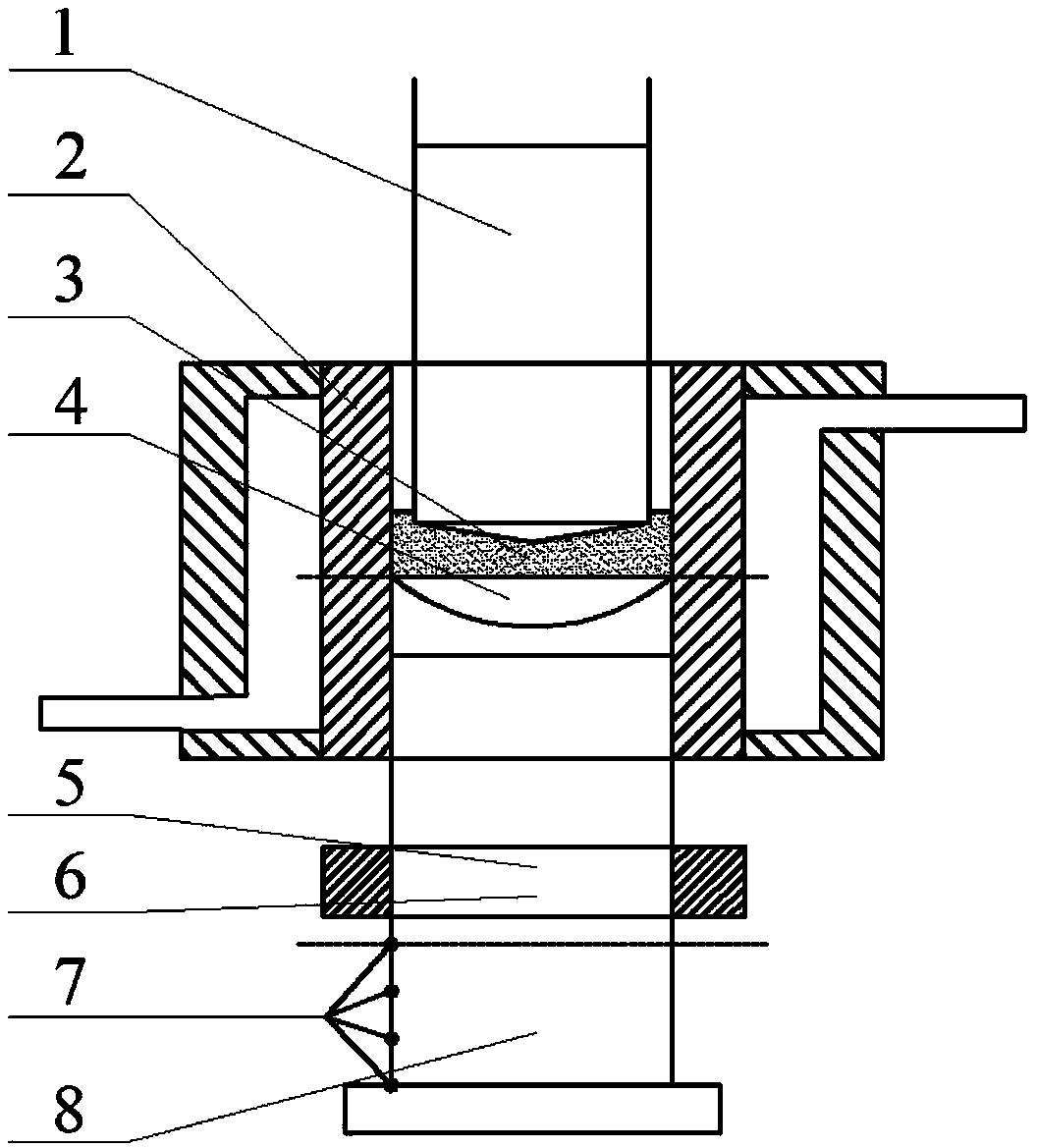

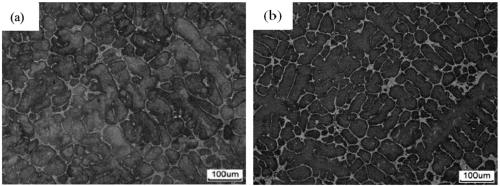

[0033] The electrode rod is used as the electroslag remelting anode for remelting refining, using such as figure 1 The shown ingot electroslag remelting furnace. In this embodiment, two different electroslag remelting processes are used. One is the traditional crystallizer-placed electroslag remelting furnace, and the produced electroslag ingot specifications are Φ220mm; the other is the pumping electroslag remelting furnace, which is electric The slag ingot specification is Φ220mm. The test material is M2 high-speed steel, the composition is shown in Table 1, and the slag system is CaF 2 60%, Al 2 O 3 20%, CaO 20% ternary slag system, melting temperature is greater than 1500℃, the loss of electroslag ingot is about 1% of the weight of the electrode rod, the electroslag remelting process parameters are shown in Table 2 below, the electroslag remelting process production The electroslag ingot cooling rate is faster and there is a large residual stress inside. In order to preve...

Embodiment 2

[0046] The electrode rod is used as the electroslag remelting anode for remelting refining, using such as figure 1 The shown ingot electroslag remelting furnace. In this embodiment, two different electroslag remelting processes are used. One uses a traditional crystallizer-mounted electroslag remelting furnace, and the produced electroslag ingot specifications are Φ300mm; the other uses an ingot electroslag remelting furnace, which The ingot specification is Φ300mm. The test material is M2 high-speed steel, the composition is shown in Table 3 below, the slag system is CaF2 60%, Al2O3 20%, CaO 20% ternary slag system, melting temperature is greater than 1500℃, the loss of electroslag ingot is about electrode The electroslag remelting process parameters are shown in Table 4 below. The electroslag ingot produced by the electroslag remelting process has a faster cooling rate and large residual stress inside. In order to prevent cracking, the electroslag The ingot is preheated in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com