Prestress tensioning control system

A control system and prestressing technology, which is applied in the control system, control/adjustment system, mechanical pressure/force control, etc., can solve the problems of large elongation measurement error, poor stability, and low precision of tension control, and achieve improved The effect of construction quality, good stability and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate those skilled in the art to understand the technical solution of this patent, the technical solution of this patent will be further described in the form of specific cases below.

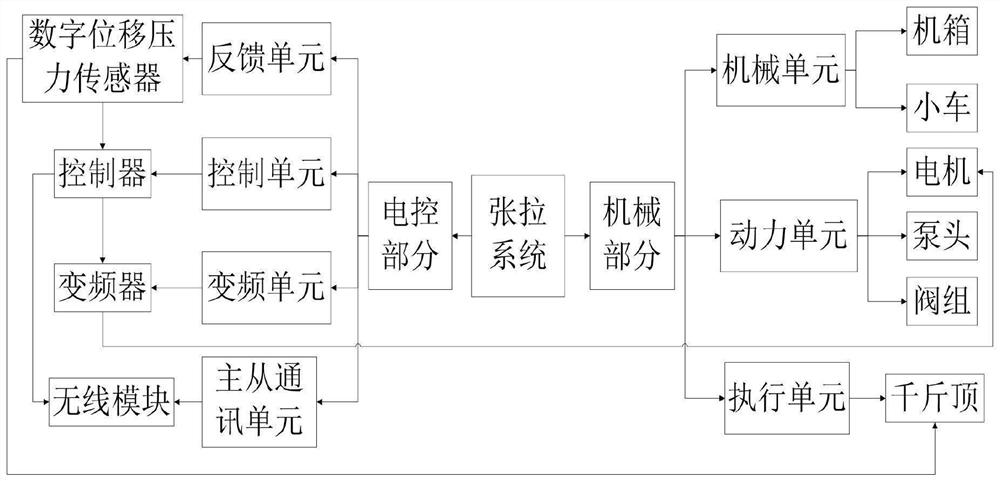

[0028] Such as figure 1 As shown, a prestressed tensioning control system includes a main tensioning machine and a secondary tensioning machine, and both the main tensioning machine and the secondary tensioning machine include a control unit, a feedback unit, a mechanical unit, a power unit, an execution unit and a wireless communication module ; The power unit includes a motor, a pump head and a valve group, the pump head is soaked in the oil tank of the mechanical unit and driven by the motor, the motor is controlled by a frequency converter, and the pump head is provided with an oil outlet port and is connected with the valve group through a mechanical unit; the execution unit includes a jack and a digital displacement pressure sensor; the digital displacement pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com