Gas-liquid two-phase jet flow oil pipe outer surface cleaning experiment device and method

An experimental device and external surface technology, applied in the direction of measuring devices, flow characteristics, instruments, etc., can solve the problems of high nozzle structure requirements, affecting cleaning effect, consuming jet energy, etc., to achieve good cleaning effect, reasonable experimental design, and real-time measured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

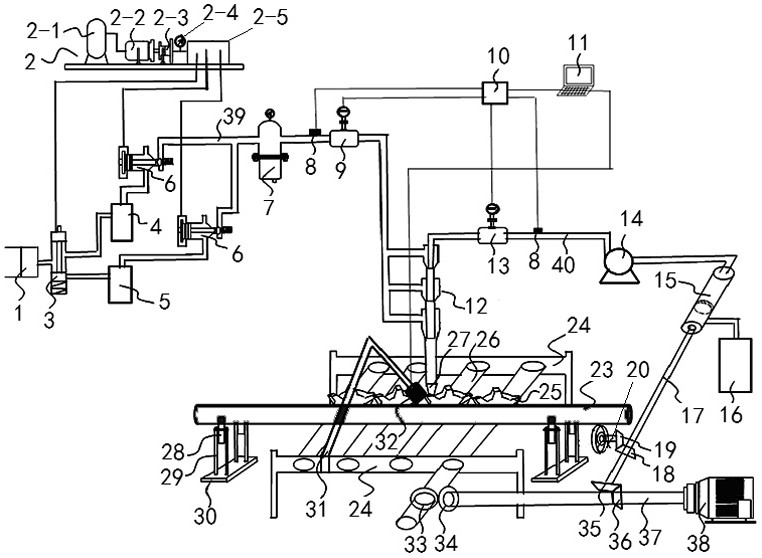

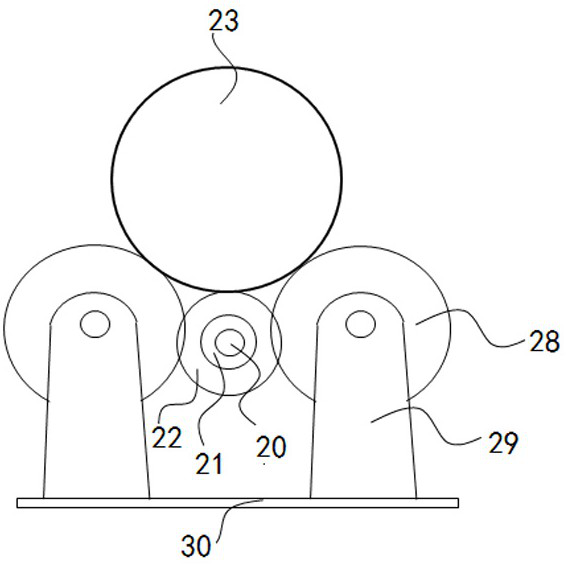

[0038] Embodiment 1, an experimental device for cleaning the outer surface of a gas-liquid two-phase jet oil pipe mentioned in the present invention, including a screw air compressor 1, a hydraulic workstation 2, a hydraulically controlled two-position three-way valve 3, an air storage tank 4, and a spare storage tank. Gas tank 5, hydraulic control check valve 6, precision gas filter 7, pressure sensor 8, vortex flowmeter 9, data acquisition system 10, computer 11, three-stage gas-liquid mixer 12, turbine flowmeter 13, high-pressure screw Pump 14, automatic centrifugal filter 15, water storage tank 16, centrifugal shaft 17, first bevel gear 18, second bevel gear 19, rotating transmission shaft 20, transmission sleeve 21, elastic friction layer 22, oil pipe to be cleaned 23, Transmission bracket 24, linkage roller 25, transmission roller 26, nozzle 27, roller 28, oil pipe support frame 29, support plate 30, fixed bracket 31, high-speed camera 32, third bevel gear 33, fourth beve...

Embodiment 2

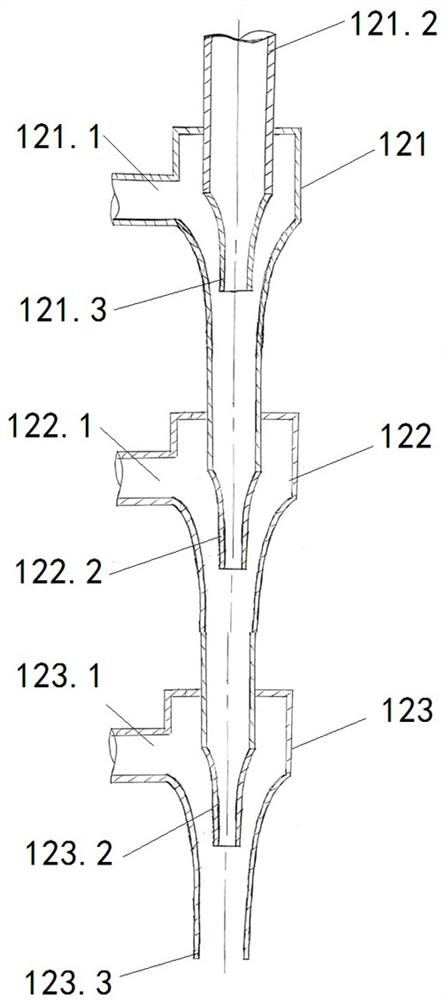

[0063] Embodiment 2, the gas-liquid two-phase jet oil pipe outer surface cleaning experimental device mentioned in the present invention, differs from Embodiment 1 in that: the three-stage gas-liquid mixer 12 mentioned in the present invention includes a primary gas-liquid mixing chamber 121 , the secondary gas-liquid mixing chamber 122, the tertiary gas-liquid mixing chamber 123, the top center of the primary gas-liquid mixing chamber 121 is provided with a first liquid inlet 121.2, the outer side is provided with a first gas inlet 121.1, and the first liquid inlet 121.2 is connected to The lower end of the first central liquid pipe is the first liquid outlet 121.3, and the two-phase flow formed by the preliminary mixing of liquid and gas from the first liquid outlet 121.3 enters the secondary gas-liquid mixing chamber 122, and is sprayed out through the second liquid outlet 122.2 The second gas inlet 122.1 is provided on the outside of the secondary gas-liquid mixing chamber ...

Embodiment 3

[0065] Embodiment 3, the experimental device for cleaning the outer surface of the gas-liquid two-phase jet oil pipe mentioned in the present invention, differs from Embodiment 2 in that: the cavity of the gas-liquid mixing chamber of each stage is composed of a gas channel a, a contraction section b, Composed of cylindrical section c and expansion section d; a plurality of gas channels are evenly and staggeredly distributed on the circumference of the gas-liquid mixing chamber, and are located in different horizontal directions, so that the gas-liquid can be mixed more fully.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap