Stabilized curing method for inorganic fluoride landfill type waste and application

A curing method and fluoride technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of poor anti-leaching performance of hazardous waste, affecting the effect of hazardous waste disposal, and unqualified leaching toxicity indicators. , to achieve the effect of good fluorine-fixing effect, saving production cost and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

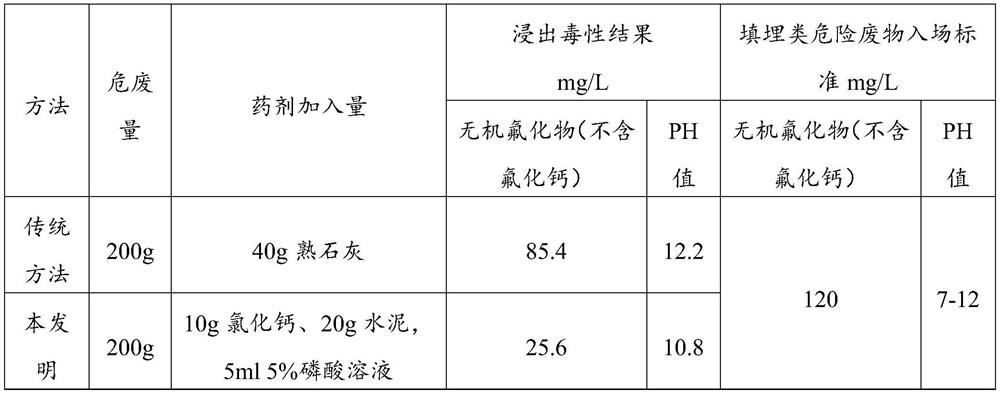

Embodiment 1

[0026] A method for stabilizing and solidifying inorganic fluoride landfill hazardous waste, comprising the following steps:

[0027] (1) Add 5 parts by weight of calcium chloride solution to the broken hazardous waste to obtain mixture A;

[0028] (2) Add 10 parts by weight of cement to mixture A to obtain mixture B;

[0029] (3) Add 1 part by weight of 5% phosphoric acid solution to mixture B to obtain mixture C.

[0030] (4) After the mixture C has been cured and all indicators meet the entry standards for landfill hazardous waste, it will be landfilled.

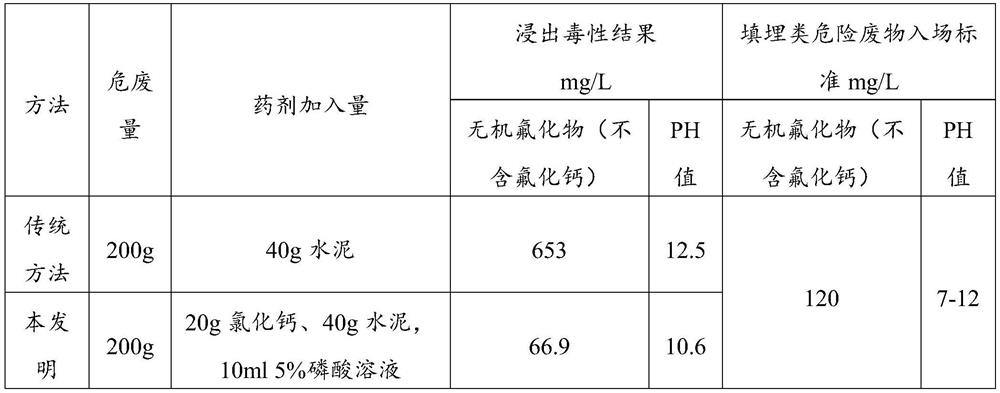

Embodiment 2

[0032] A method for stabilizing and solidifying inorganic fluoride landfill hazardous waste, comprising the following steps:

[0033] (1) Add 10 parts by weight of calcium chloride solution to the broken hazardous waste to obtain mixture A;

[0034] (2) Add 20 parts by weight of cement in mixture A to obtain mixture B;

[0035] (3) Add 1 part by weight of 5% phosphoric acid solution to mixture B to obtain mixture C.

[0036] (4) After the mixture C has been cured and all indicators meet the entry standards for landfill hazardous waste, it will be landfilled.

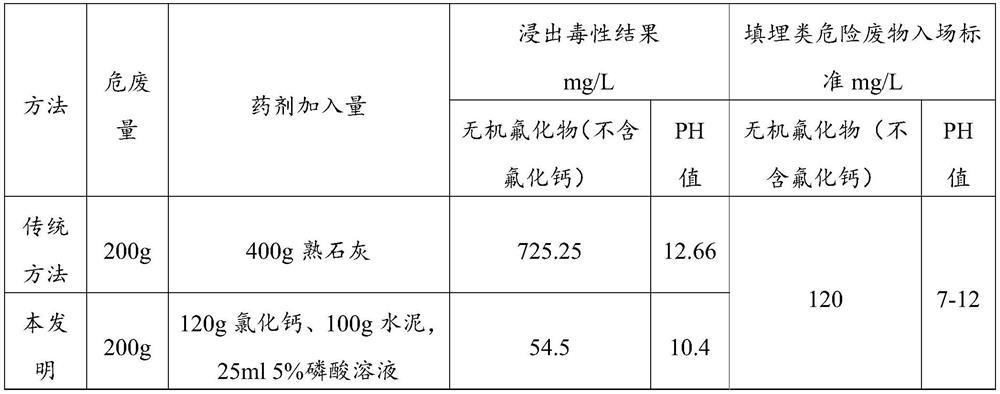

Embodiment 3

[0038] A method for stabilizing and solidifying inorganic fluoride landfill hazardous waste, comprising the following steps:

[0039] (1) Add 60 parts by weight of calcium chloride solution to the broken hazardous waste to obtain mixture A;

[0040] (2) in mixture A, add the cement of 50 parts by weight to obtain mixture B;

[0041] (3) Add 12.5 parts by weight of phosphoric acid solution to mixture B to obtain mixture C.

[0042] (4) After the mixture C has been cured and all indicators meet the entry standards for landfill hazardous waste, it will be landfilled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com