A kind of experimental method of solidifying radioactive graphite powder at room temperature

A technology of room temperature curing and experimental methods, which is applied in the fields of radioactive purification and nuclear engineering, which can solve the problems of immature technology, poor stability of plastic materials, and in-depth research, so as to avoid leakage problems, low shrinkage rate, and excellent anti-leaching Effects of Sex and Irradiation Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

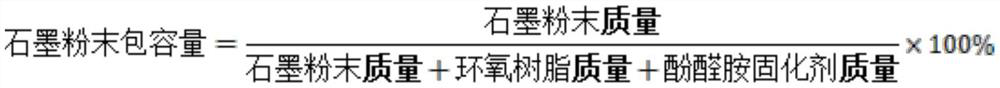

[0022] First prepare the Nd(NO 3 ) 3 , Sr(NO 3 ) 2 , CsNO 3 and Co(NO 3 ) 2 The simulated nuclide mixed feed liquid, so that the concentration of each ion in the feed liquid is 135.6g / LNd 3+ , 146.8g / LSr 2+ , 107.7g / LCs + and 128g / LCo 2+ ;The calculation method of package capacity is as follows:

[0023]

[0024] Under normal temperature conditions, weigh 15g of epoxy resin, 1.05g of nuclear graphite powder (200 mesh), 5g of T-31 phenalkamine curing agent (5% capacity); first mechanically stir the mixture of epoxy resin and graphite material for 10min , so that the epoxy resin and the graphite material are fully mixed, and the Nd(NO 3 ) 3 , Sr(NO 3 ) 2 , CsNO 3 and Co(NO 3 ) 2 Then add T-31 phenalkamine curing agent; continue to stir for 10 minutes; pour the flowable mixture into the mold, press the mold, and store it at room temperature; disassemble the mold after two weeks, and take out the cured body; When the radiation dose is not more than 10 6 Irradi...

Embodiment 2

[0026] Under normal temperature conditions, weigh 15g of epoxy resin, 3.6g of graphite powder for nuclear use (325 mesh), 5g of T-31 phenalkamine curing agent (capacity is 15.2%); first mechanically stir the mixture of epoxy resin and graphite material 30min, the epoxy resin and the graphite material are fully mixed, and the Nd(NO 3 ) 3 , Sr(NO 3 ) 2 , CsNO 3 and Co(NO 3 ) 2 100ul of the mixed material liquid, and then add T-31 phenalkamine curing agent; continue to stir for 15 minutes; pour the flowable mixture into the mold, press the mold, and store it at room temperature; disassemble the mold after two weeks, and take out the cured body; When the radiation dose is not more than 10 6 Irradiate the cured body under the condition of Gy, detect the chemical stability of the cured body; use the static immersion method to study the Nd of the cured body of epoxy resin-graphite material 3+ 、Sr 2+ 、Cs + and Co 2+ Ion leaching performance, detected after 42 days, simulated...

Embodiment 3

[0028] Under normal temperature conditions, weigh 15g of epoxy resin, 8.6g of nuclear graphite powder (400 mesh), 5g of T-31 phenalkamine curing agent (30% capacity); first mechanically stir the mixture of epoxy resin and graphite material 60min, the epoxy resin and the graphite material are fully mixed, and the Nd(NO 3 ) 3 , Sr(NO 3 ) 2 , CsNO 3 and Co(NO 3 ) 2 Then add T-31 phenalkamine curing agent; continue to stir for 30 minutes; pour the flowable mixture into the mold, press the mold, and store it at room temperature; disassemble the mold after two weeks, and take out the cured body; When the radiation dose is not more than 10 6 Irradiate the cured body under the condition of Gy, detect the chemical stability of the cured body; use the static immersion method to study the Nd of the cured body of epoxy resin-graphite material 3+ 、Sr 2+ 、Cs + and Co 2+ Ion leaching performance, detected after 42 days, simulated nuclide removes Cs before and after irradiation + T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com