Laser welding beam shaping optimization device

A beam shaping and optimization device technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of unadjustable spot size and uncontrolled flat-top spot, so as to solve the problem of uncontrolled and optimize beam quality , The effect of focusing the beam uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following will clearly and completely describe the technical solutions of the present invention with reference to the drawings in the embodiments of the present invention.

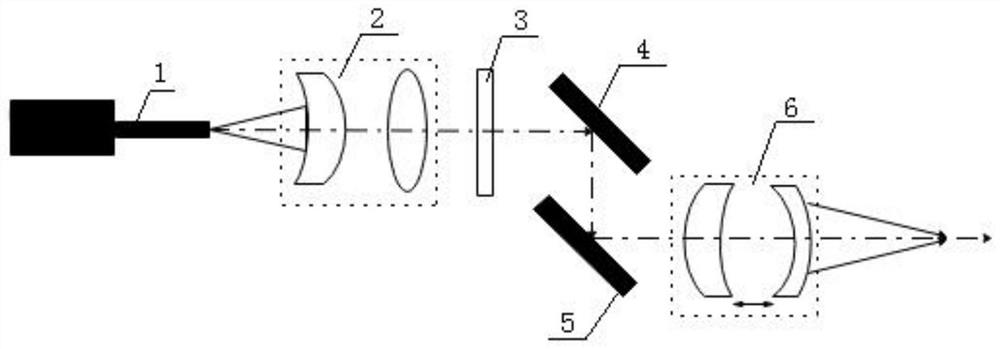

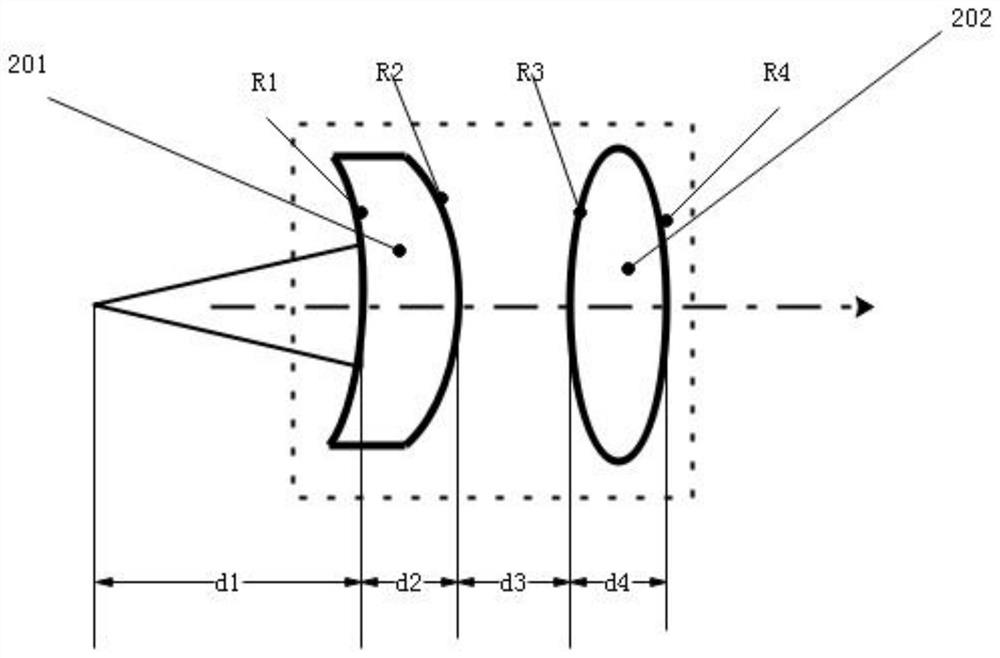

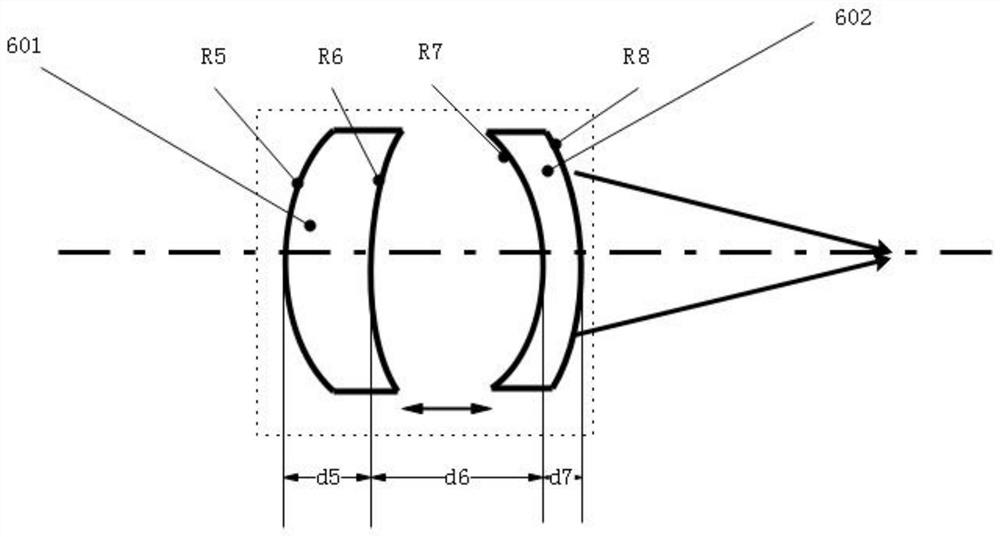

[0029] see Figure 1 to Figure 3 , this embodiment discloses a laser welding beam shaping optimization device, including a collimating lens group 2, a shaping lens group 3, and a focusing lens group 6, and the collimating lens group 2 is used to convert the laser light emitted by the laser 1 into a parallel Light, and output to the shaping mirror group 3, the shaping mirror group 3 is used to homogenize the collimated Gaussian beam, modulate the beam with Gaussian distribution into a beam with uniform energy distribution, and output the modulated beam to the focusing mirror Group 6, the focusing lens group 6 is used to focus the modulated light onto the surface to be welded. The focusing lens g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| sphericity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com