Device for simultaneously polishing double surfaces of waterproof sealing strip

A waterproof sealing and double-sided technology, which is applied in the direction of grinding drive, grinding machine, transportation and packaging, etc., can solve the problems of low grinding efficiency, small grinding force surface, sealing strip clamping and tensioning problems, etc. Consistency, increased sanding efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

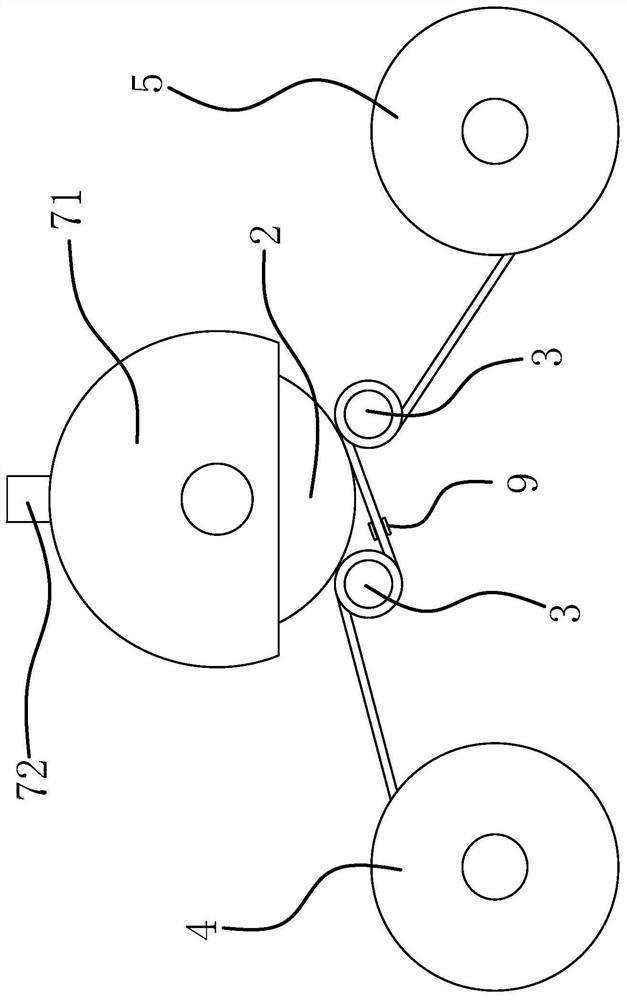

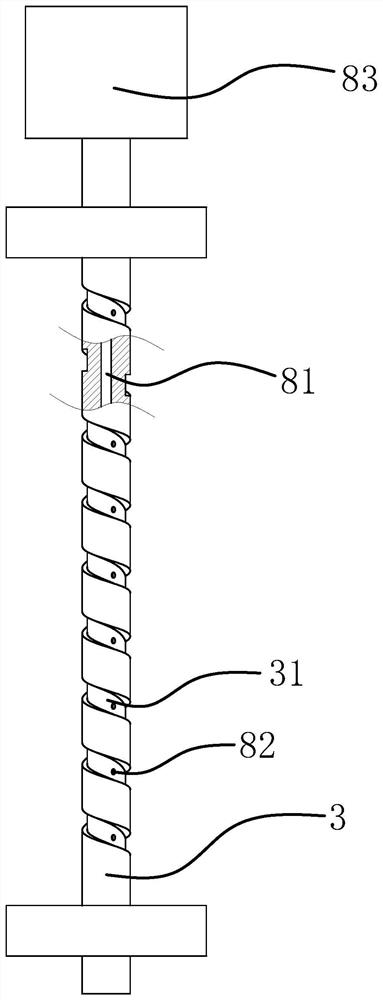

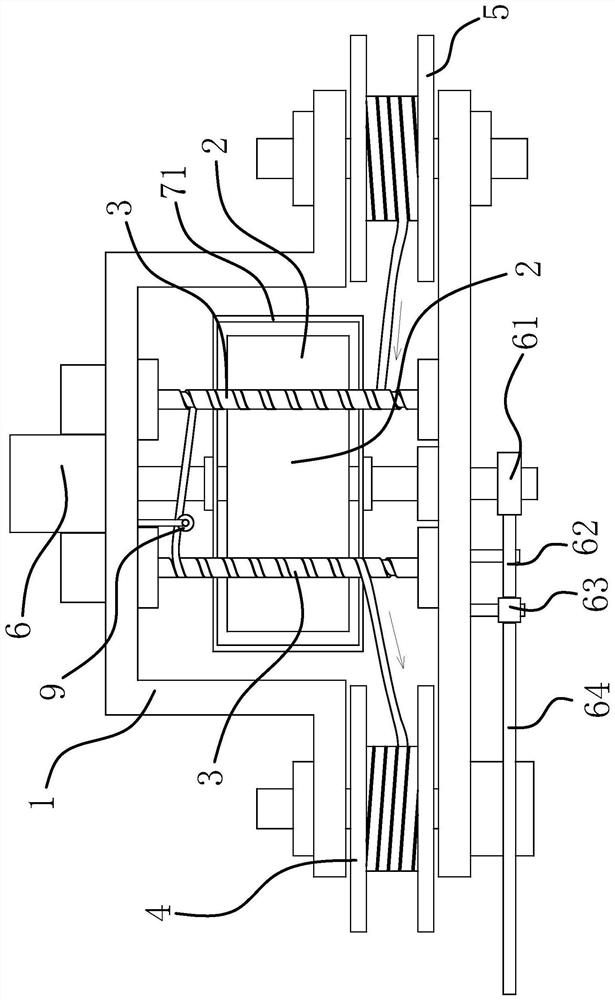

[0028] Such as figure 1 , figure 2 and image 3 As shown, it includes a machine base 1, a grinding wheel 2, two positioning screws 3, a retracting wheel 4 and a discharge wheel 5, and the grinding wheel 2 is connected to the machine base 1 in rotation, and the grinding wheel 2 is driven by a drive motor 6 to position The screw rod 3 is fixedly connected to the machine base 1, the axis of the positioning screw rod 3 is parallel to the axis of the grinding screw rod, the positioning screw rod 3 has a spiral guide groove 31 adapted to the width of the waterproof sealing strip, and the two positioning screw rods 3 are arranged symmetrically On the outside of the grinding wheel 2, the waterproof sealing strip is drawn betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com