A mechanical blank assembly device for side-pressed bamboo laminated timber infinitely long laminates

An infinitely long, laminated timber technology, applied in the jointing of wooden veneers, wood processing equipment, manufacturing tools, etc., can solve problems such as low work efficiency, poor working environment, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

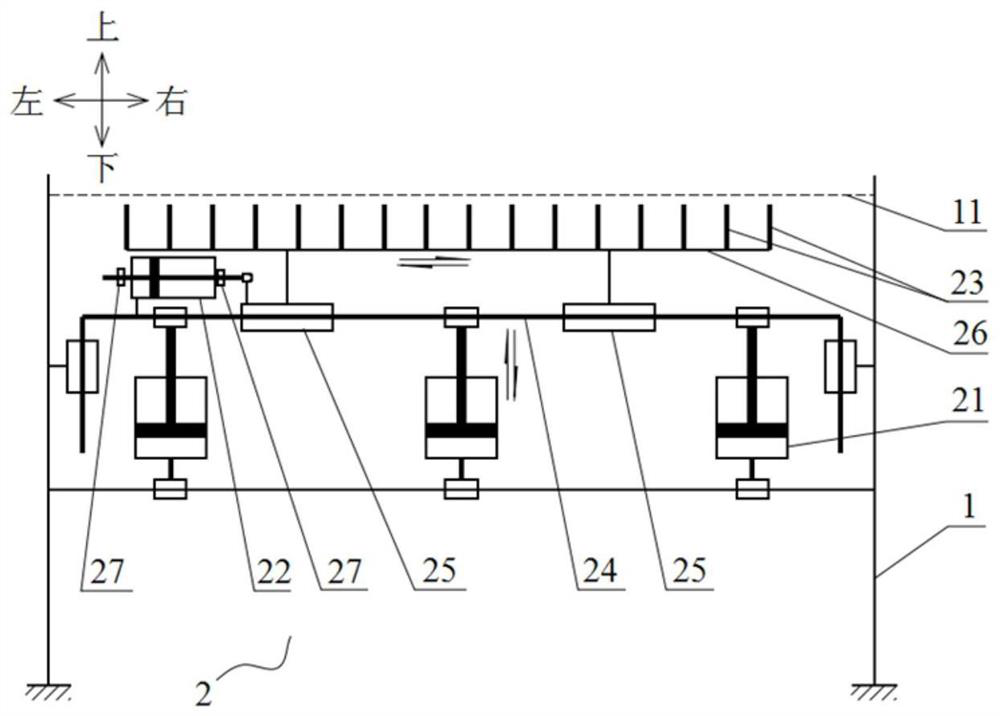

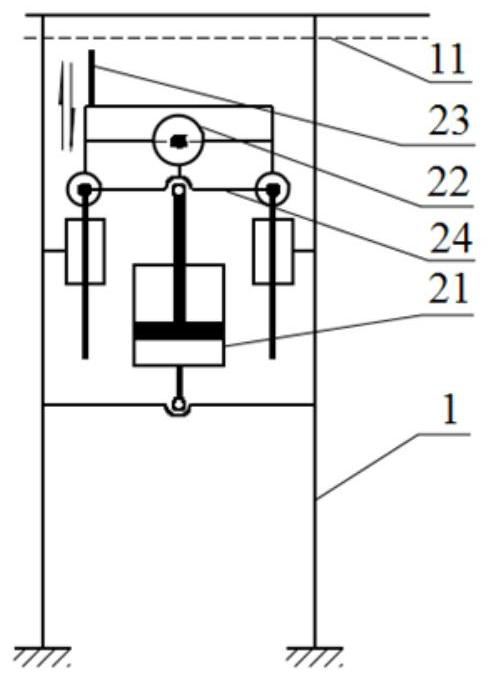

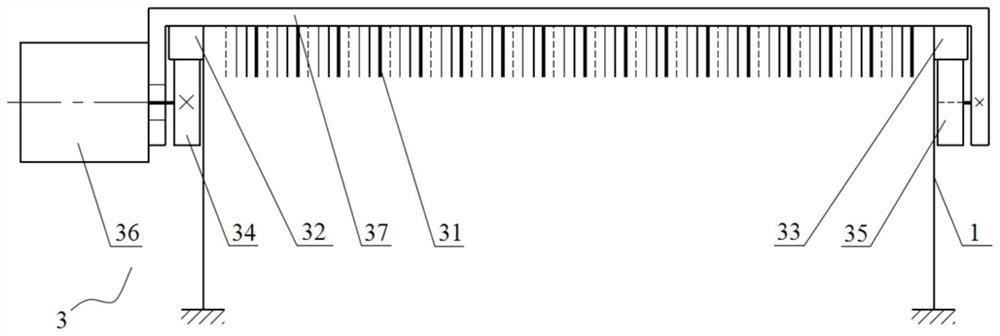

[0028] Infinitely long bamboo laminates with a cross-sectional size of 408 mm (width) × 20 mm (thickness) were machine-assembled from bamboo slices with dimensions of 1200 mm (length) × 20 mm (width) × 6 mm (thickness). First hand-made on-site or prefabricated ladder template 4: ladder template 4 is made up of 17 groups of ladder-shaped template bamboo slices 41, and the lengths of adjacent template bamboo slices 41 in each group of bamboo slice groups differ by 300mm (see Figure 6 ); send the side-standing bamboo slices 5 to be pushed laterally from the right side to the workbench 11; the rodless chamber of the vertical cylinder 21 takes in air, and the push rod 23 (the distance is 24 mm) of the horizontal push mechanism 2 rises On the workbench 11, it is as high as the standard bamboo slices 5; the left cavity of the horizontal cylinder 22 is air-intake, and the material lever 23 moves laterally to the right, so that the free end of the longest formwork bamboo slice 411 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com