Full-angle drill carriage

An all-angle, drilling rig technology, applied in the mechanical field, can solve problems such as injury accidents, low efficiency, and harsh operating environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

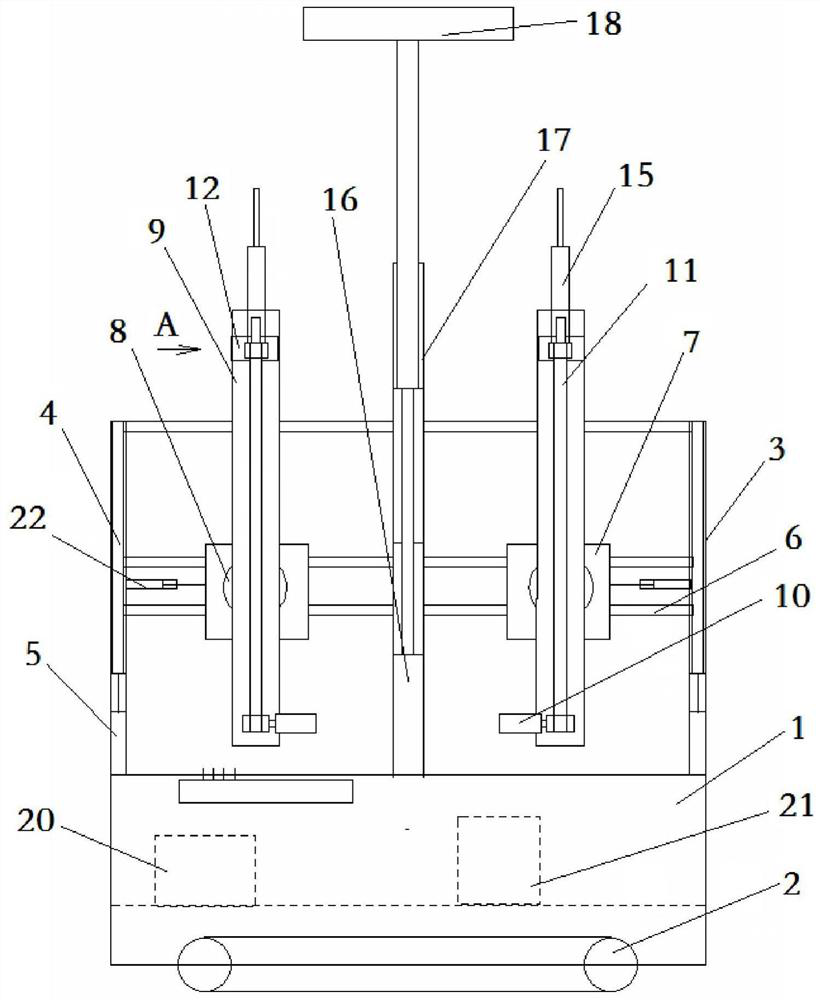

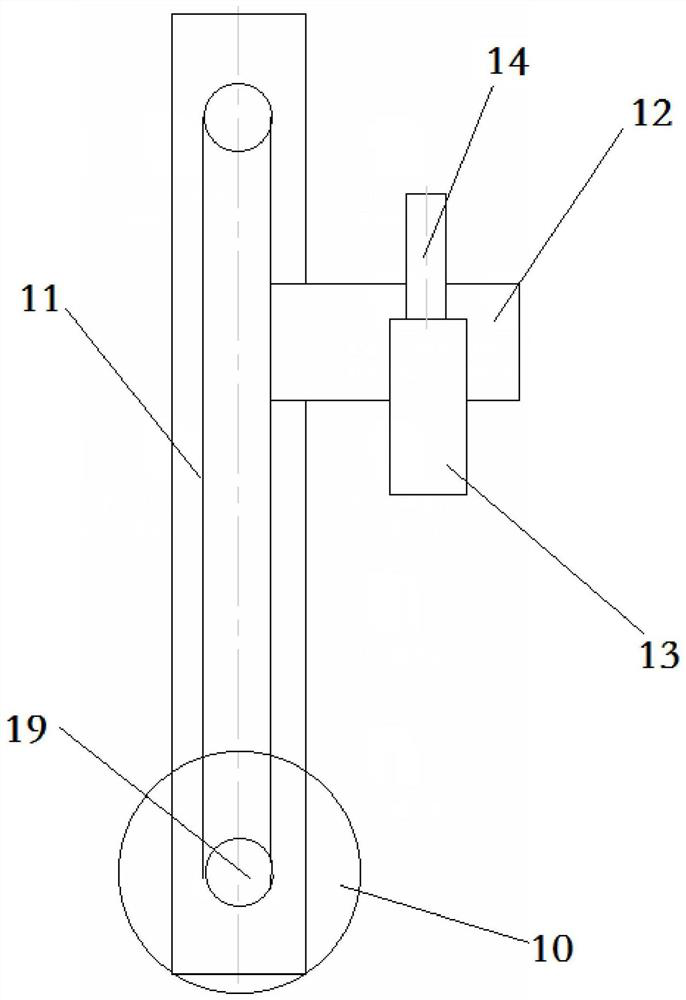

[0012] The present invention is specifically described below in conjunction with accompanying drawing, as shown in the figure, the crawler belt 2 driven by hydraulic motor is set at the lower end of vehicle frame 1; The piston end is connected, and the sliding support 4 is arranged in the support cover 3 and can slide along the support cover 3; a slideway 6 is arranged between the sliding support 4, and a slide block 7 is arranged on the slideway; the slide block 7 is connected with the piston end of the horizontal hydraulic cylinder 22; A rotary drive 8 is set on the slider 7, and the rotary drive is an outsourced product, which can be the SE7-73-H-16R product of Xuzhou Wanda Slewing Bearing Co., Ltd.; a drill pipe support 9 is set on the rotary drive 8; The lift motor 10 is arranged below the support 9, and the output end of the lift motor drives the chain wheel 19, and the chain wheel 19 drives the chain 11 to rotate, and one end of the drill bit seat is fixed on the describ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com