While-drilling anti-overflow pipe liquid level monitoring device and method

A liquid level monitoring and anti-overflow pipe technology, which is used in measurement, earth-moving drilling, wellbore/well components, etc., can solve the problems of target device design defects, sudden changes in flow, and difficulty in accurate measurement of flow monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Hereinafter, the device and method for monitoring the liquid level of an overflow prevention pipe while drilling according to the present invention will be described in detail with reference to the accompanying drawings and exemplary embodiments.

[0038] One aspect of the present invention provides a liquid level monitoring device for an anti-overflow pipe while drilling.

[0039] In an exemplary embodiment of the device for monitoring the liquid level of an overflow prevention pipe while drilling according to the present invention, the device may include a reflective unit, a laser emitting unit, a laser receiving unit, a processing unit and a computing unit.

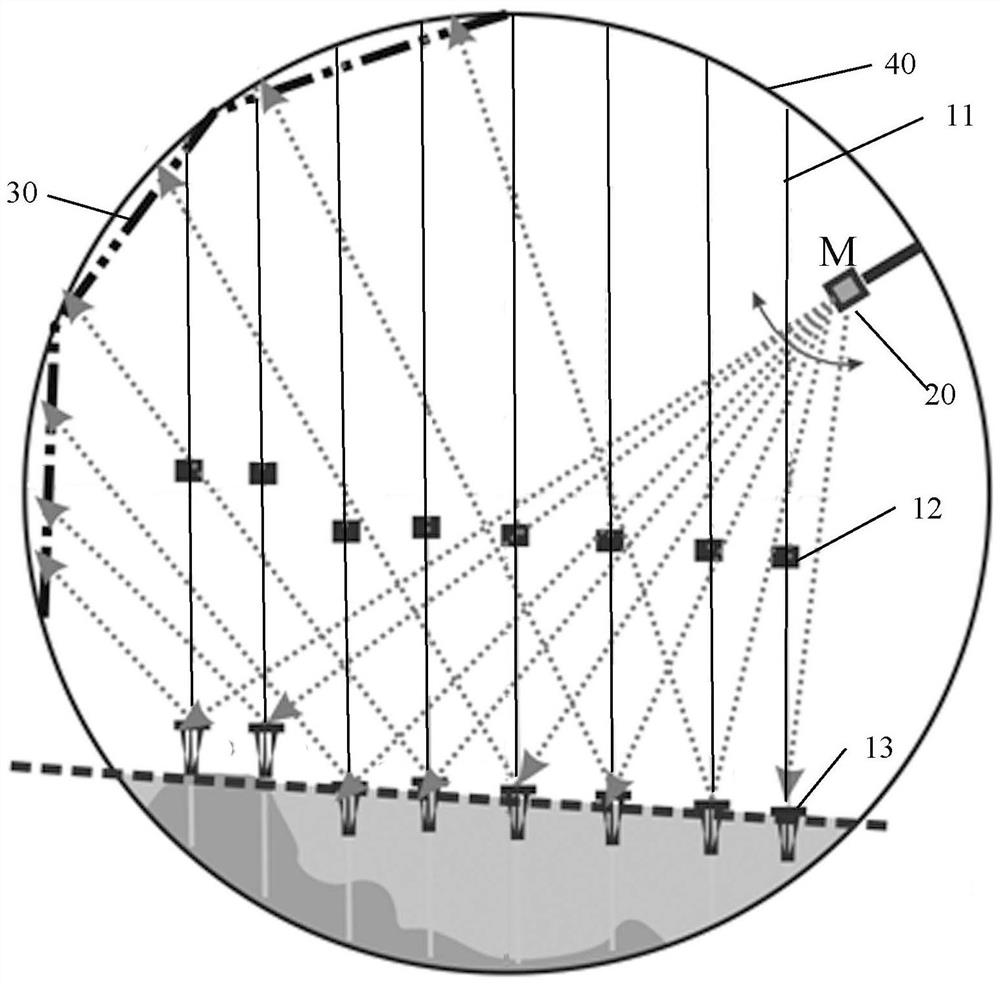

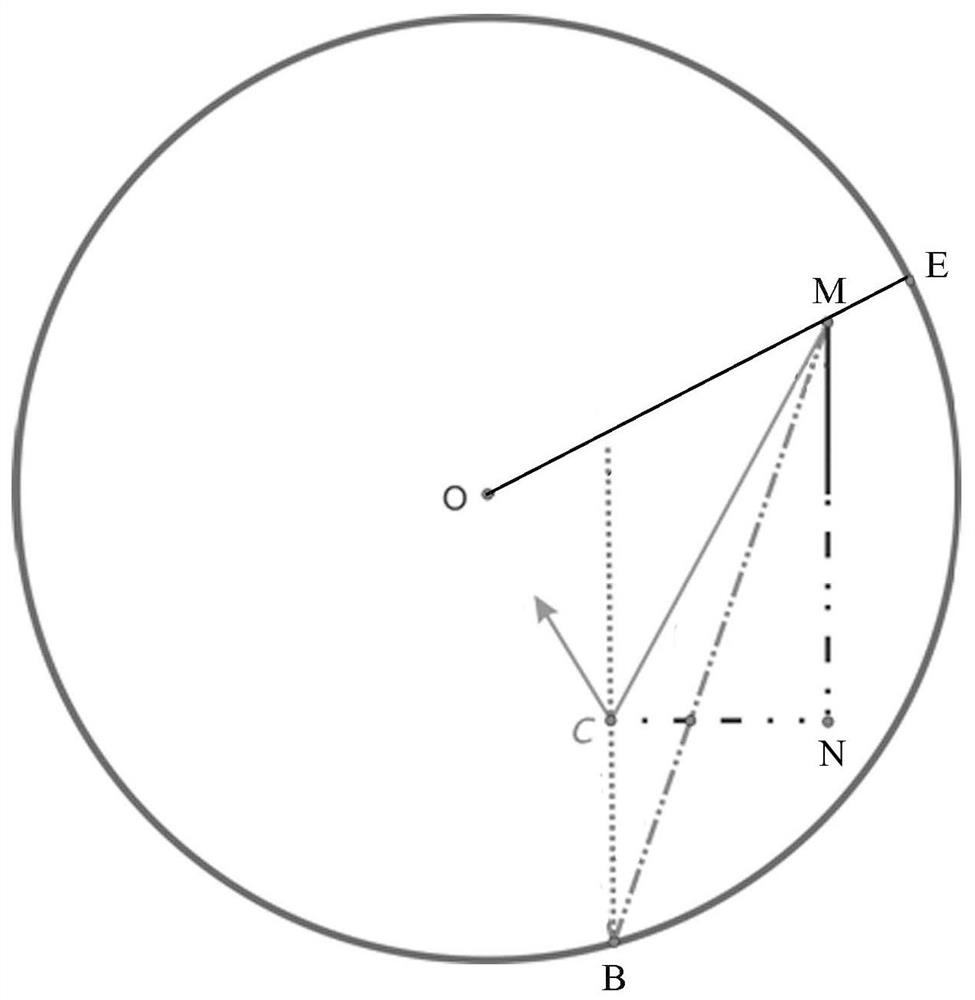

[0040] Wherein, the reflection unit may include n reflection assemblies arranged radially of the overflow prevention pipe, for example, 1, 2, 3, 5, 8, 11 and so on. Such as figure 1 and 2 As shown, each reflection assembly includes a slide rail 11 , a lifting mechanism 12 and a reflection plate 13 . The slide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap