Plate blank movement simulation method for roller hearth type heating furnace

A roller hearth heating furnace and motion simulation technology, applied in the field of computational fluid dynamics, can solve problems such as the inability to simulate the billet movement in the furnace, and achieve the effects of optimizing furnace operation, short contact time, and saving testing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

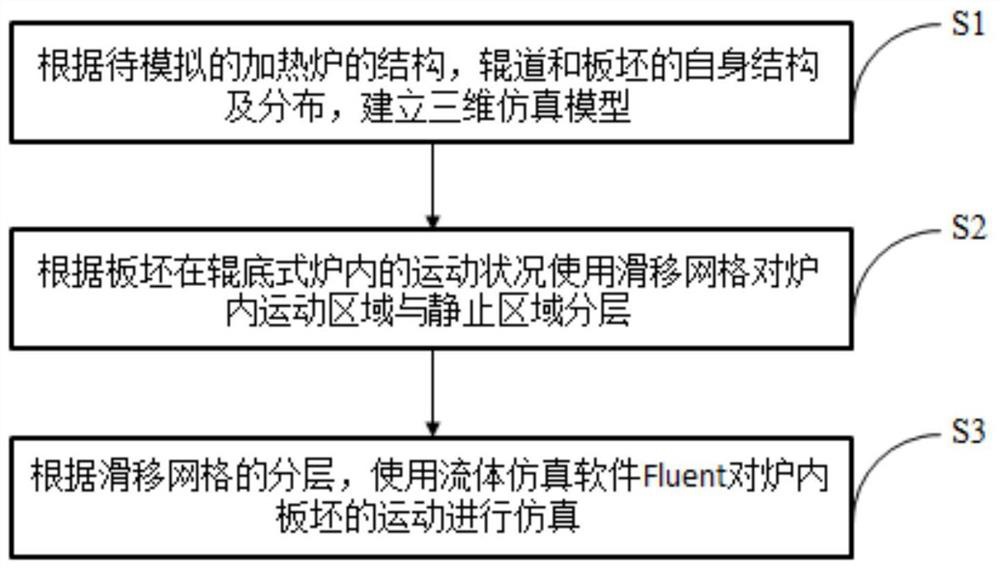

[0043] Such as figure 1 As shown, the present invention provides a method for slab motion simulation of a roller hearth heating furnace, comprising the following steps:

[0044] S1. Establish a three-dimensional simulation model according to the structure of the heating furnace to be simulated, the structure and distribution of the transport roller and the slab;

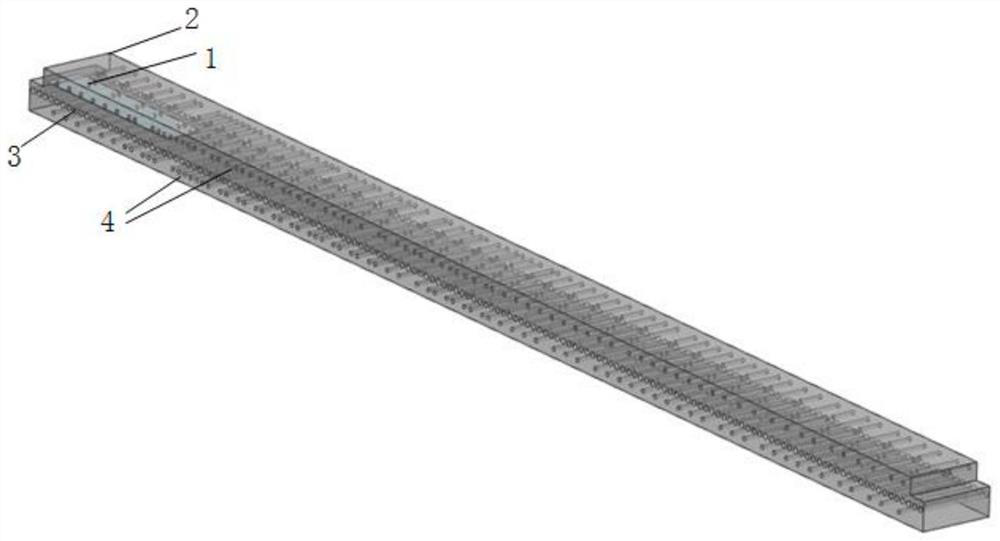

[0045] The three-dimensional models of the slab, furnace body, transport roller and radiant tube wall are respectively established. The spatial structure of a radiant tube 4 is referred to figure 2 .

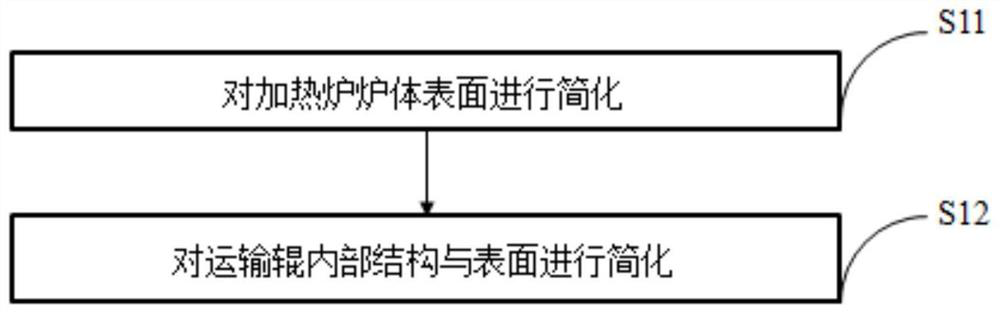

[0046] Among them, see image 3 , step S1 simplifies the three-dimensional simulation model of the heating furnace, including:

[0047] S1.1, Simplify the surface of the heating furnace body;

[0048] The wall surface of the heating furnace body is treated as a thin wall surface, the thickness of the furnace wall is ignored and the furnace wall is regarded as an insulating surface.

[0049] S1.2, Simplify the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com