A cold slag removal method applied to robot welding

A robot welding and welding slag technology, which is applied in the field of robots, can solve the problems of welding work impact, welding table surface contusion, etc., and achieve the effect of increasing the contact area and improving the separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

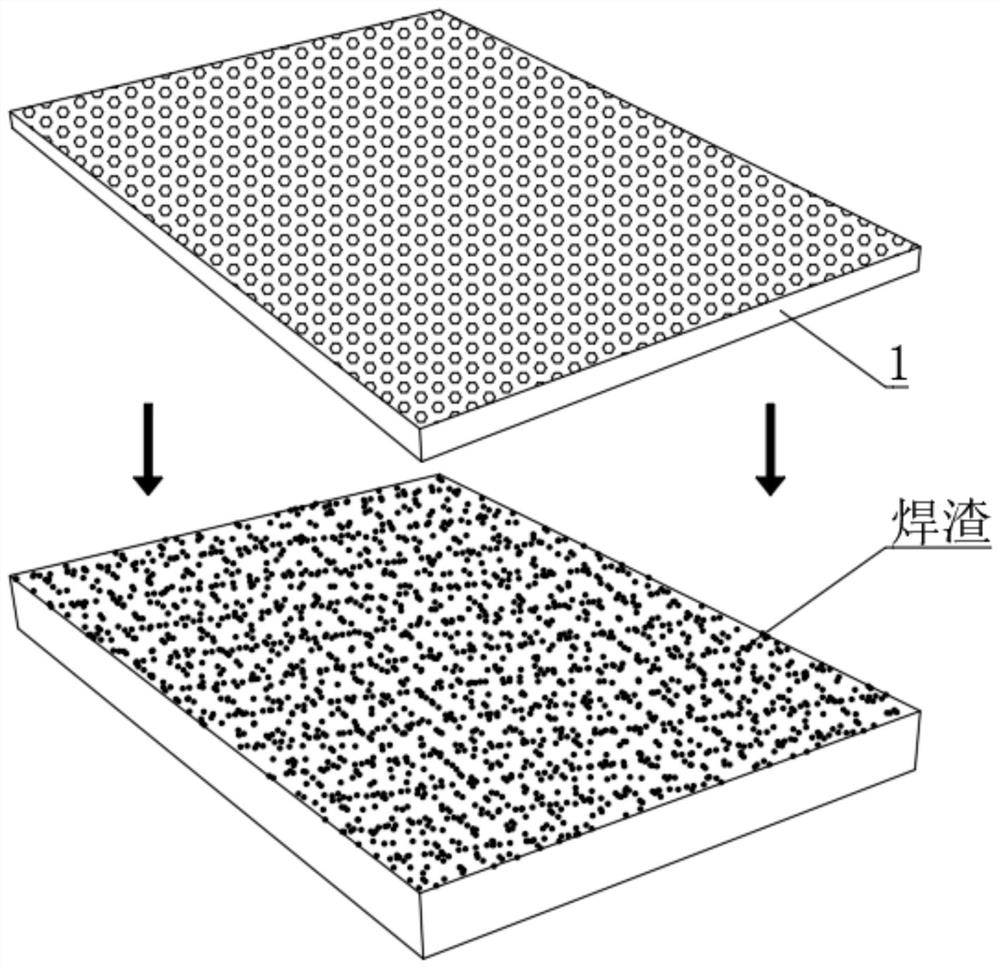

[0042] see figure 1 , a kind of cold type welding slag removal method that is applied to robot welding, comprises the following steps:

[0043] S1. Sprinkle cold water on the welding table after welding to cool down the welding table, and keep the cold water covering the entire surface of the welding table under the action of welding slag;

[0044] S2. Spread the pre-dissolved board 1 on the surface of the welding table, and cool the upper side of the pre-dissolved board 1, so that the droplets formed by the liquefaction of water vapor in the air continue to drop on the pre-dissolved board 1 on the upper surface until the surface of the pre-dissolved patch 1 freezes;

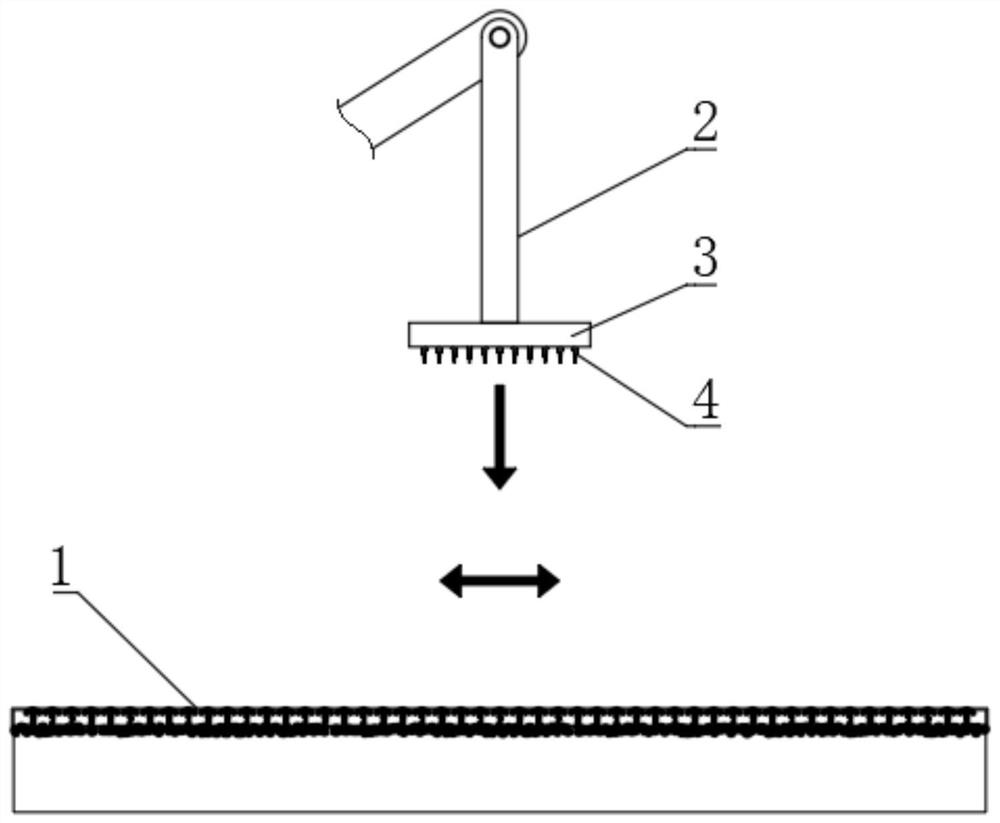

[0045] S3. Start the mechanical arm 2 to move and rub against the surface of the pre-dissolved board 1 to speed up the breaking of the ice cubes, and take away the welding slag on the welding table during the ice breaking process.

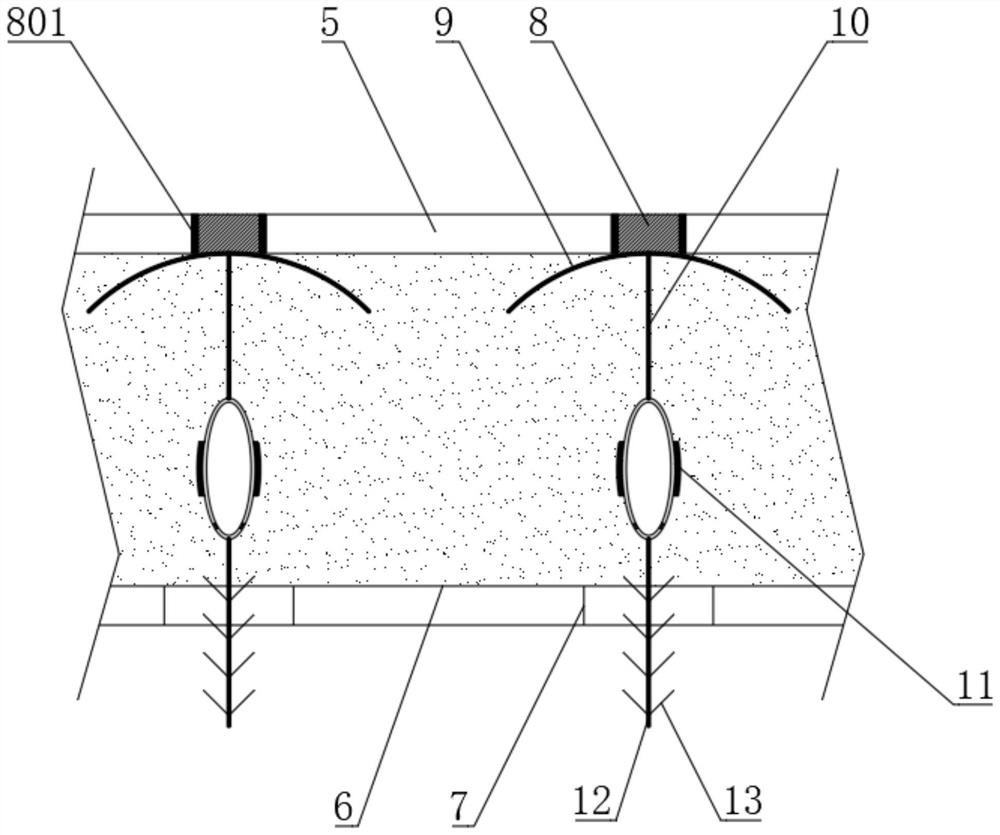

[0046] see figure 1 and image 3 , the pre-dissolved patch 1 in S2 includes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com