Manufacturing process of breeding floater and breeding floater obtained by process

A manufacturing process and technology for floats, applied in the field of maintaining air pressure in floats and floats, can solve the problems of long production cycle, high manufacturing cost, gas leakage, etc., and achieve the effect of saving materials and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

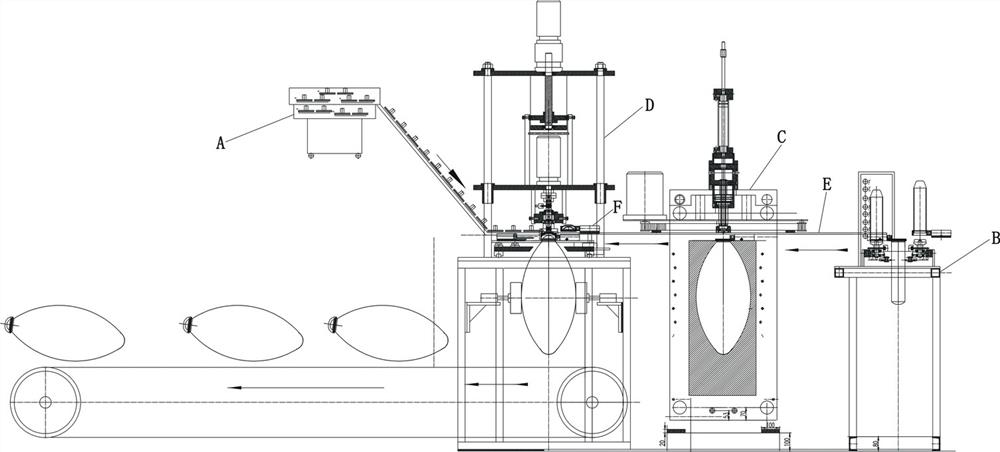

[0043] Below in conjunction with accompanying drawing, the manufacturing process of the culture float of the present invention is described in detail:

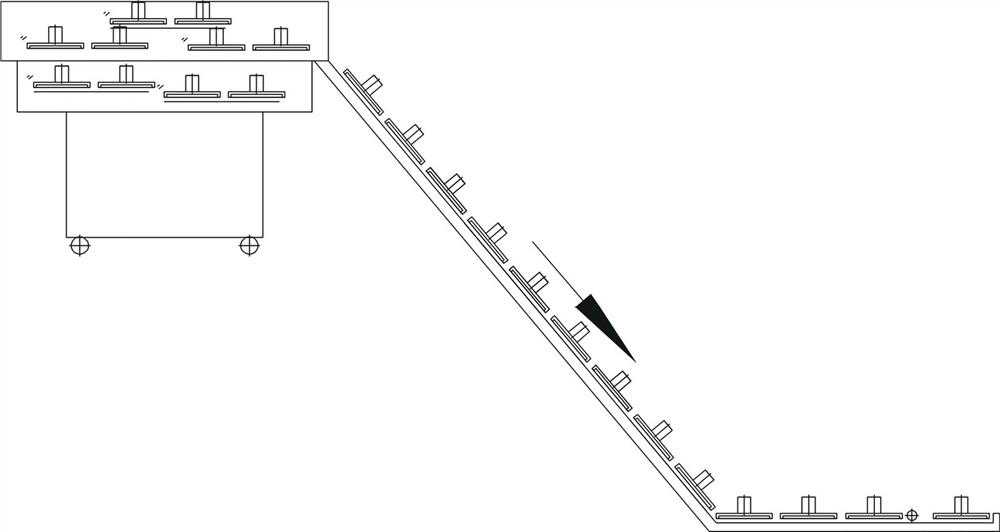

[0044] refer to figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 and figure 1 , the heating device B, the blowing device C, the cap sorting device A and the welding device D are connected together by the suspension rail E. After the preform is heated by the heating device B, it is sent to the blowing device C through the suspension rail E. Bottle blowing in C, after the bottle body c is formed, the bottle body c is sent to the welding device D from one side through the suspension rail E, and at the same time, the cap sorting device A sends the sealing cap a to the welding device D from the other side, and the The handling device F places the sealing cap a on the bottle mouth of the bottle body c.

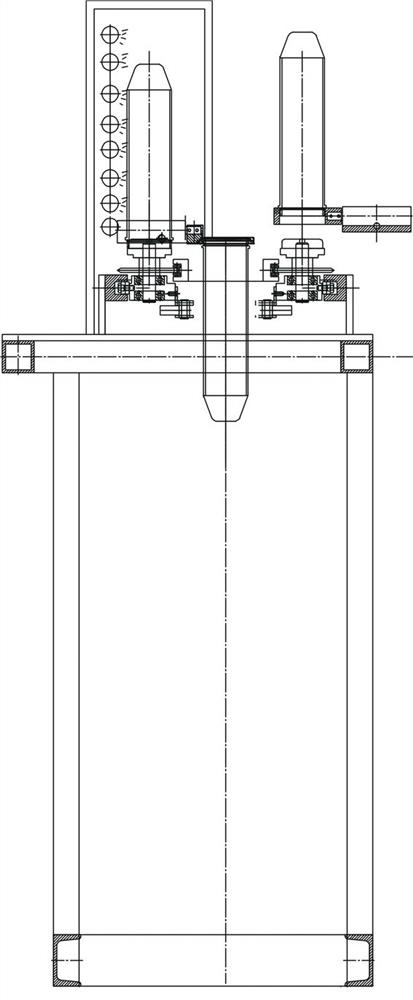

[0045] refer to Figure 5 and Figure 8, in the welding device D, including the first se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com