Operation and switching method for different propulsion modes of direct-current networking hybrid power propulsion system

A hybrid power and propulsion system technology, which is applied in the direction of engines, propulsion components, and control systems using propulsion device combinations, and can solve problems such as time-consuming, specific control methods of shaft motors that are not involved, power output breakpoints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0118] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

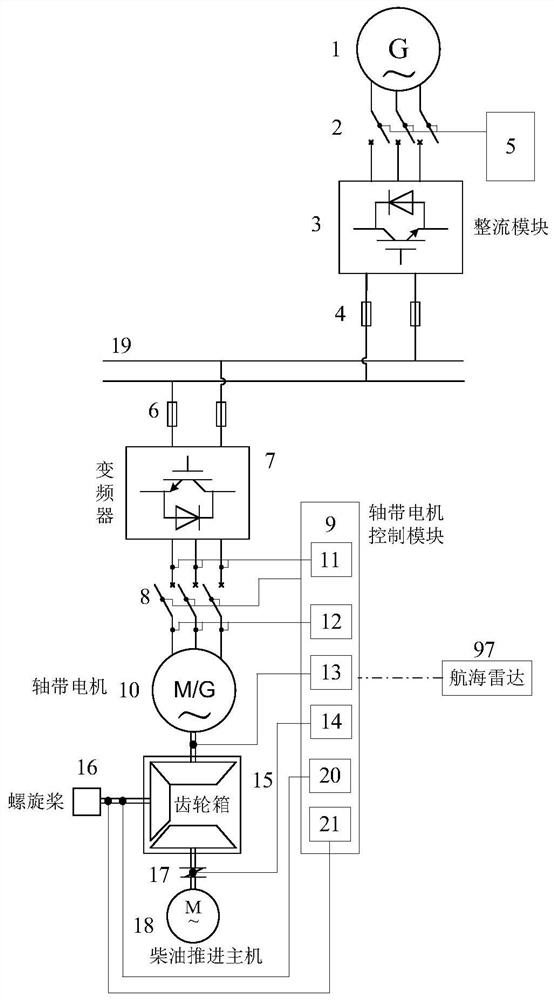

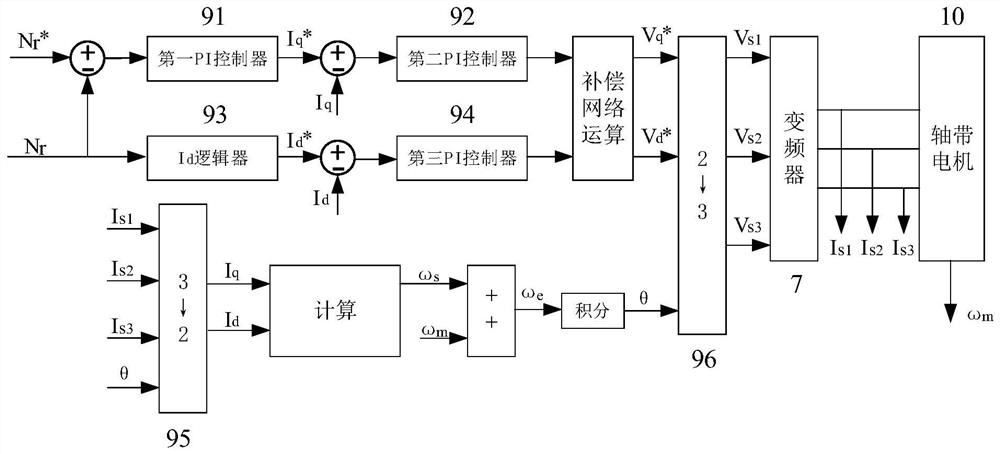

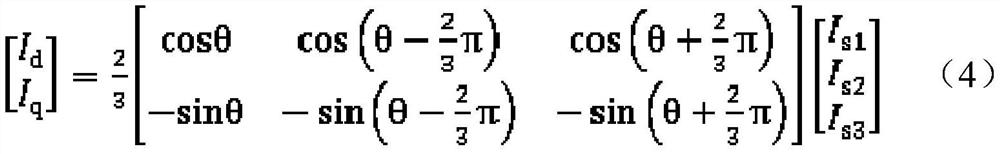

[0119] Such as Figure 1-2 As shown, the hybrid power propulsion system based on DC networking includes a DC bus 9, and a power generation module and a shaft-belt propulsion mechanism are connected to the DC bus 9. The power generation module includes a diesel generator set 1, and the diesel generator set 1 is connected to a first circuit breaker 2, a rectifier module 3, and a first fuse 4 sequentially through a power supply line, and the cable is finally connected to a DC bus 9. In addition, the power generation mechanism also includes a power generation module controller 5 for controlling opening and closing of the first circuit breaker 2 . The shaft-belt propulsion mechanism includes a diesel propulsion host 18, the diesel propulsion host 18 is connected to the first end of the three-terminal gearbox 15 through a clutch 17, the second end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com