Multi-strand twisting machine

A twisting machine and twisting technology, which is applied in the direction of textiles and papermaking, and can solve the problem that multiple strands of thin wires cannot be evenly arranged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

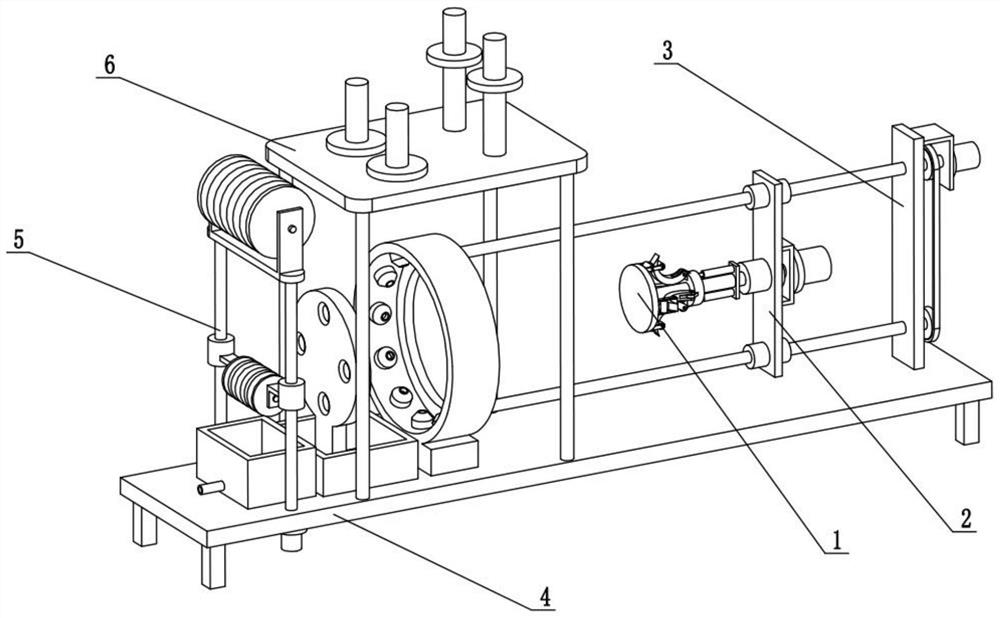

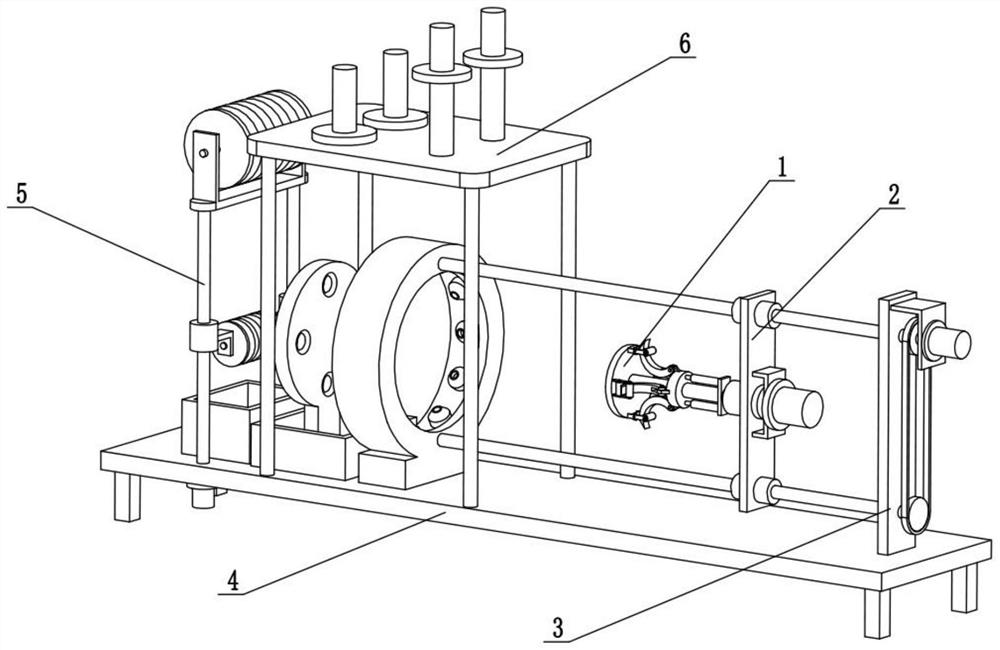

[0025] Combine below Figure 1-8 Describe this embodiment. The present invention relates to the field of textile technology, more specifically, a multi-strand twisting machine, including a suspension automatic telescopic mechanism 1, a twisting thread follow-up tensioning mechanism 2, a tensioning drive mechanism 3, and a position-limiting wetting mechanism. Mechanism 4, guide immersion mechanism 5 and wire reel placement follow-up mechanism 6, wire reel placement follower mechanism 6 is fixedly connected on the limit wetting mechanism 4, guide immersion mechanism 5 is fixedly connected on the limit wetting mechanism 4, pull The tightening drive mechanism 3 is fixedly connected to the limit wetting mechanism 4, the twisted thread follow-up tensioning mechanism 2 is connected to the tensioning drive mechanism 3 through threads, and the suspension automatic telescopic mechanism 1 is fixedly connected to the twisted thread follow-up tensioning mechanism 2 superior.

[0026] Plac...

specific Embodiment approach 2

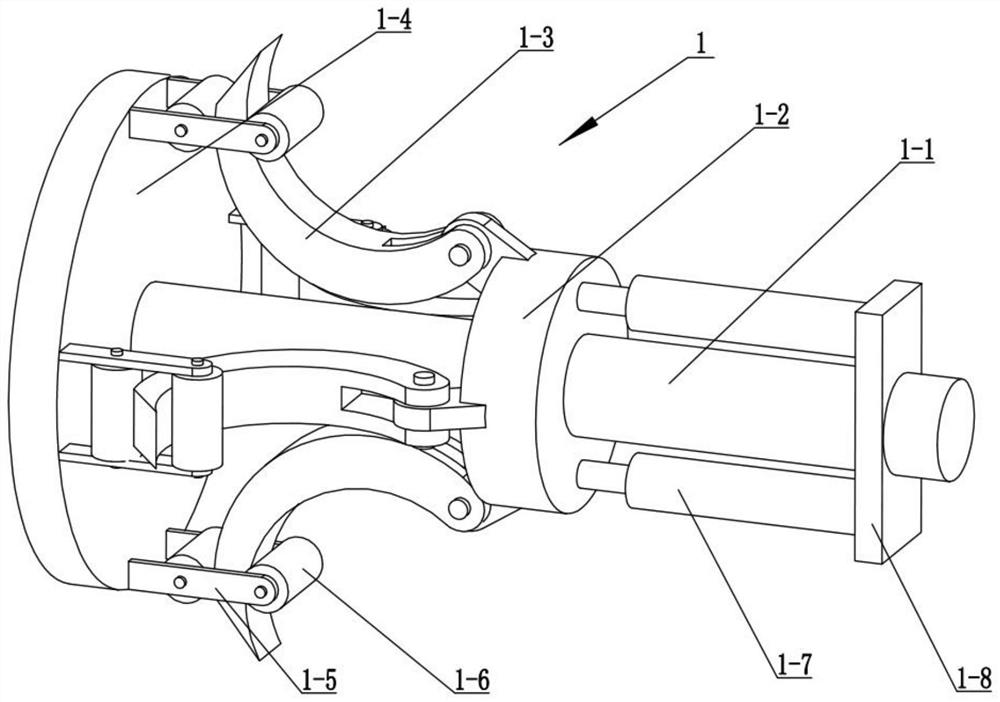

[0028] Combine below Figure 1-8 Describe this embodiment, this embodiment will further explain the first embodiment, the suspension automatic telescopic mechanism 1 includes a horizontal rotating rod 1-1, a moving sleeve 1-2, an arc-shaped telescopic hook 1-3, and a circular top plate 1 -4, limit telescopic frame 1-5, auxiliary limit roller 1-6, mobile cylinder 1-7 and cylinder mounting plate 1-8, cylinder mounting plate 1-8 is fixedly connected to the right side of horizontal rotating rod 1-1, The moving shaft sleeve 1-2 is slidingly connected on the horizontal rotating rod 1-1, and the right ends of the two moving cylinders 1-7 are respectively fixedly connected to the upper and lower ends of the cylinder mounting plate 1-8, and the moving shaft sleeve 1-2 is fixedly connected to the two On the cylinder rod of a moving cylinder 1-7, a plurality of arc-shaped telescopic hooks 1-3 are all rotatably connected to the moving bushing 1-2, and the circular top plate 1-4 is fixedly...

specific Embodiment approach 3

[0031] Combine below Figure 1-8 Describe this embodiment, this embodiment will further explain embodiment two, described twisted thread follow-up tensioning mechanism 2 includes tensioning riser 2-1, motor gantry 2-2, twisting motor 2-3, The tensioning threaded sleeve 2-4 and the rotating sleeve 2-5, the rotating sleeve 2-5 is rotatably connected to the middle of the tensioning vertical plate 2-1, and the two tensioning threaded sleeves 2-4 are respectively fixedly connected to the tensioning vertical plate The upper and lower ends of 2-1, the motor gantry 2-2 is fixedly connected to the tensioning vertical plate 2-1, the twisting motor 2-3 is fixedly connected to the motor gantry 2-2, and the rotating sleeve 2-5 is fixed Be connected on the output shaft of the twisting motor 2-3, and the right end of the horizontal rotating rod 1-1 is fixedly connected in the rotating sleeve 2-5.

[0032] The twisting motor 2-3 drives the rotating sleeve 2-5 to rotate, and the rotating slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com