Circulating heat exchange device and method for improving heat exchange efficiency

A technology of cyclic heat exchange and heat exchange efficiency, which is applied in the direction of air heaters, fluid heaters, lighting and heating equipment, etc., to achieve the effect of shortening the path, avoiding consumption and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

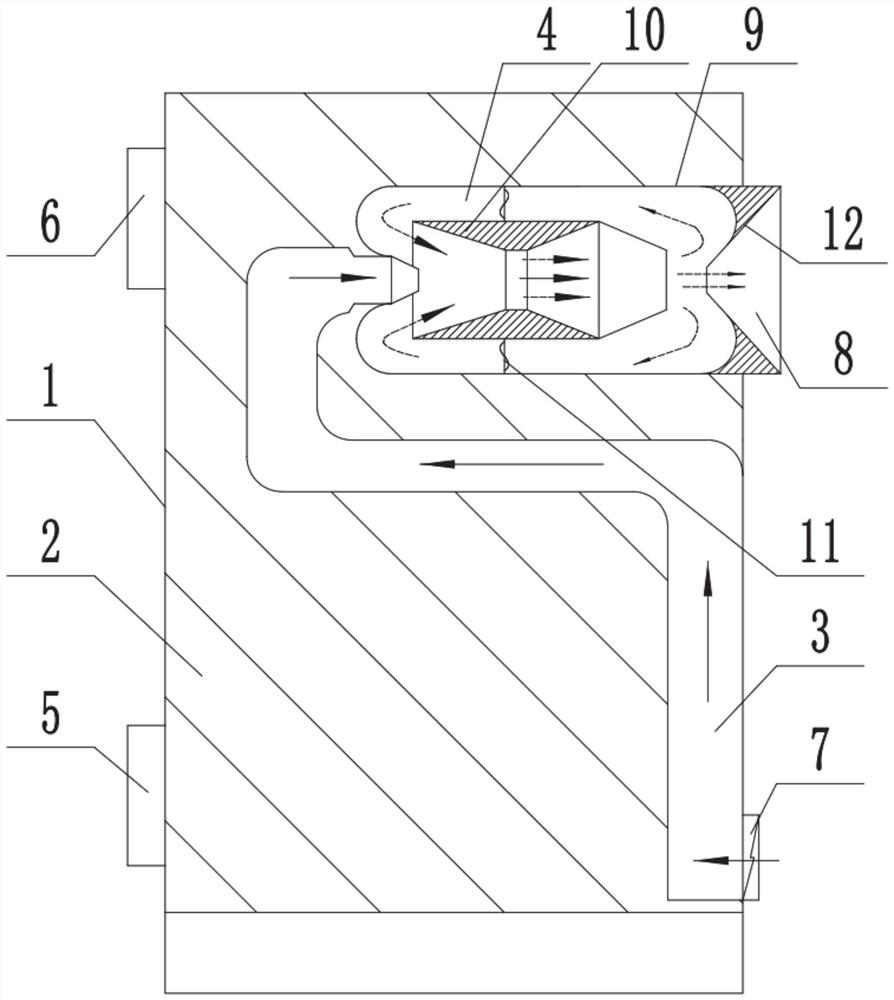

[0038] In a typical implementation of the present disclosure, a circulation heat exchange device for improving heat exchange efficiency is proposed.

[0039] It mainly includes the furnace body 1, the heat conduction pipe 3 and the circulation pipe. The heat conduction pipe and the circulation pipe are arranged in the furnace of the furnace body, and the heat is obtained from the furnace 2, and the air inside the passage is heated and output;

[0040] For the furnace body, it is a shell structure, and the interior of the furnace is a high-temperature resistant structure. In order to ensure that the furnace body will not consume indoor air and affect the indoor environment during operation, an air inlet 5 connected to the furnace body is provided on one side of the furnace body. The air outlet 6, the air inlet and the air outlet are all communicated with the outside, and the air is obtained from the outside, and the exhaust gas after combustion is discharged to the outside, avoi...

Embodiment 2

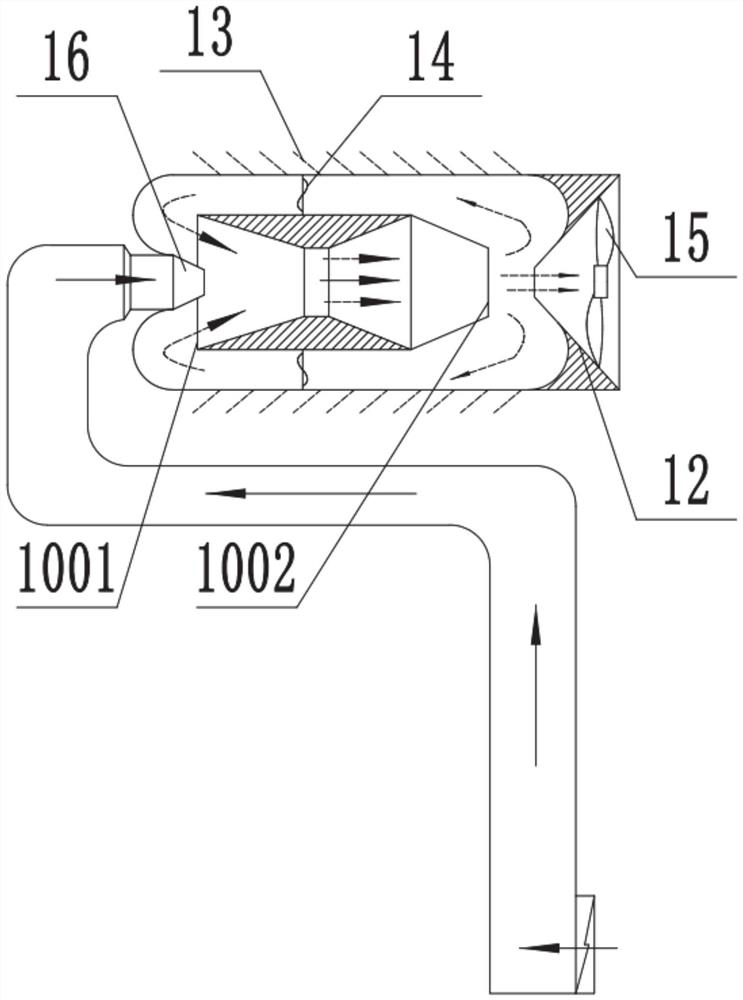

[0068] In another typical embodiment of the present disclosure, another circulation heat exchange method for improving heat exchange efficiency is provided; it utilizes the circulation heat exchange device for improving heat exchange efficiency described in Embodiment 1.

[0069] Biomass fuel burns in the furnace to release heat, which heats the heat conduction pipe and circulation pipe;

[0070] One end of the heat pipe gets air from the room, and after being heated in the heat pipe, it is input into the circulation pipe;

[0071] The air input into the circulation pipe enters the Venturi tube and flows towards the air outlet. When it is discharged from the Venturi tube, part of the air flow is directly output to the room through the air outlet, and the other part enters the circulation channel, and is heated by the return pipe for secondary circulation;

[0072] The heated air flow in the circulation channel enters the Venturi tube together with the air output from the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com