Noise equivalent temperature difference calibration method for temperature measurement thermal infrared imager

A noise-equivalent temperature difference and infrared thermal imager technology, applied in radiation pyrometry, instruments, measuring devices, etc., to achieve stable performance, simple measurement system, convenient and quick disassembly and reinstallation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

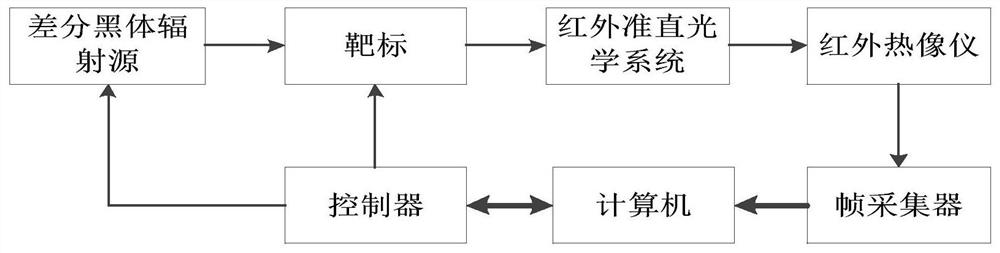

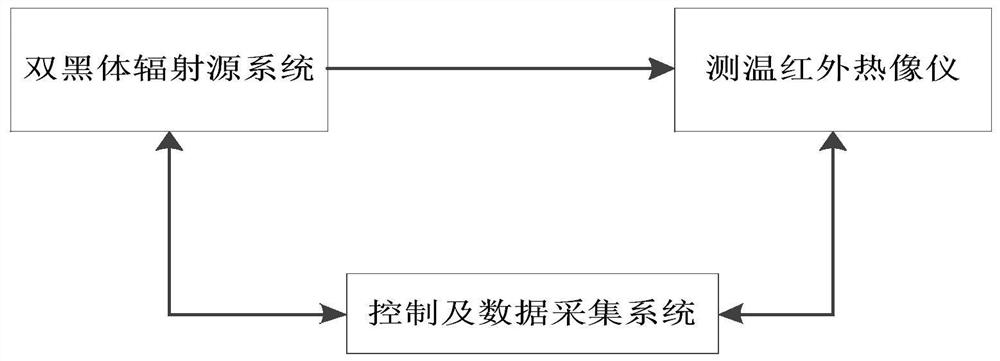

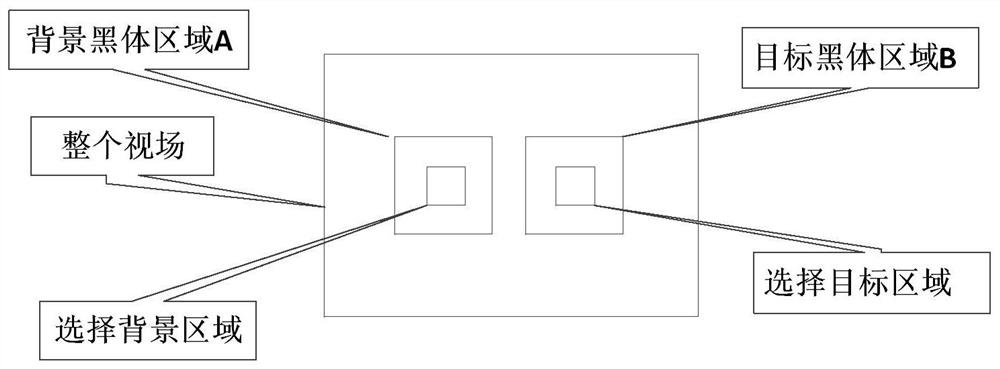

[0017] Noise equivalent temperature difference (NETD) is the temperature difference between the object and the environment required for the infrared camera to produce a signal change equal to the root mean square time noise, that is, the target and the background when the ratio of target signal to noise is 1 temperature difference. Considering that it is difficult to obtain accurate results directly when the signal-to-noise ratio is 1, the temperature difference between the target and the background is usually selected to be 3K-10K when actually measuring NETD. An embodiment of the present invention is that for the noise equivalent temperature difference calibration of the temperature measuring infrared thermal imager, it cannot be realized by using a collimator in a laboratory method. In addition, it needs to be completed on site. Therefore, the present invention uses a double black body The radiation method is used to complete the on-site calibration of the noise equivalent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com