Turbocharger actuator calibration detection structure

A turbocharger and detection structure technology, which is applied to fluid pressure measurement, instruments, and measurement devices using liquid as a pressure-sensitive medium, can solve problems such as detection failure and the inability to ensure the correctness of the input value of the detection gas source, and achieve Prevent pressure instability or, small footprint, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

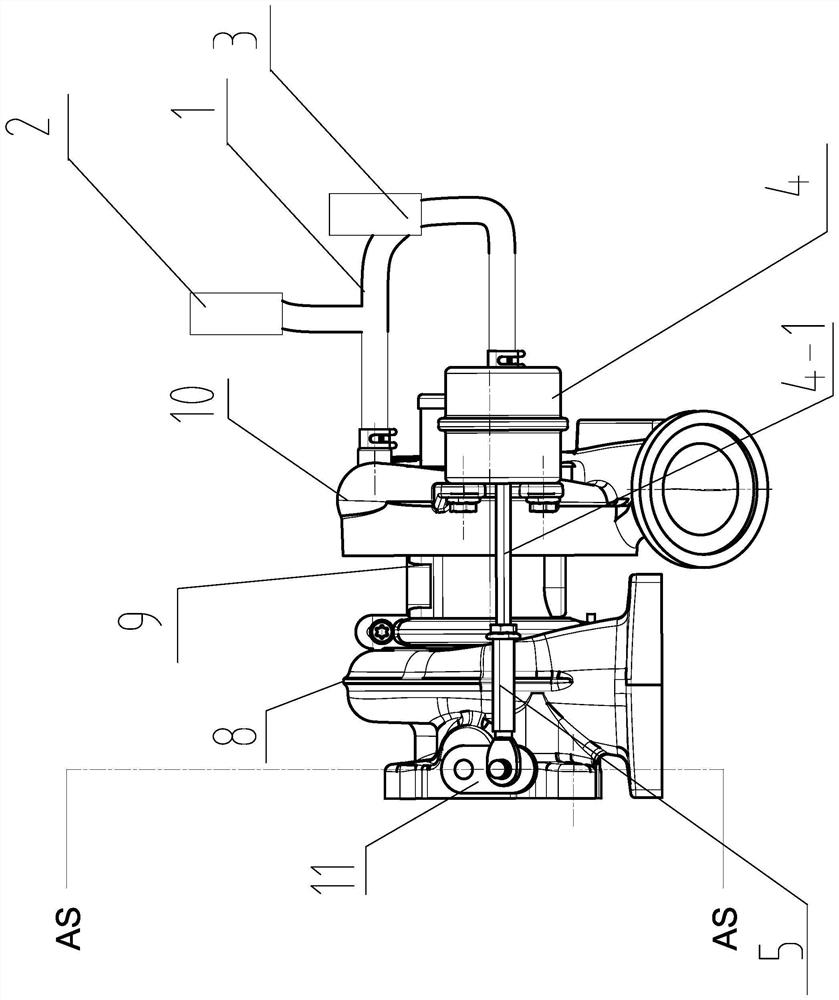

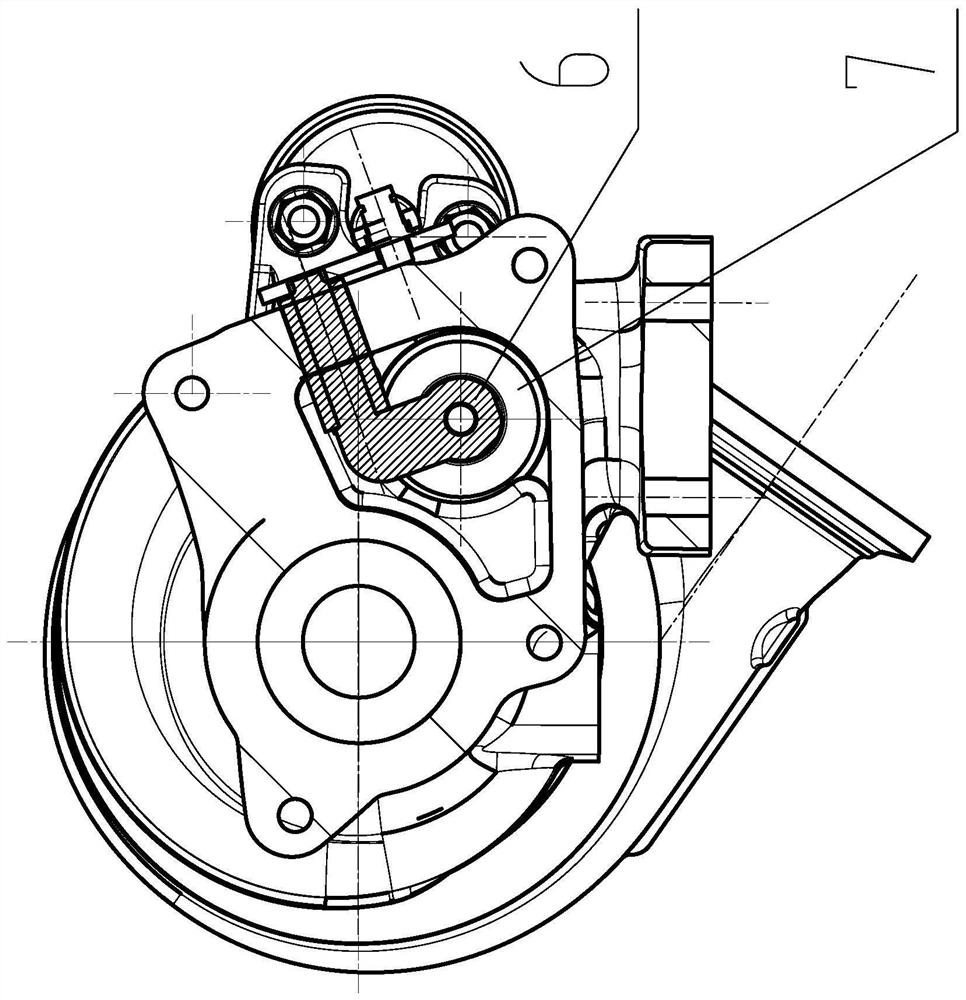

[0017] Figure 1-2 Among them, including bypass valve air pipe 1, air pressure physical detection equipment 2, air pressure electronic detection equipment 3, bypass valve 4, adjusting sleeve 5, valve stem 6, valve 7, volute 8, intermediate casing 9, pressure casing 10, Transmission plate 11 etc.

[0018] Such as Figure 1-2 As shown, the present invention is a turbocharger actuator calibration detection structure, including a turbocharger complete machine, the turbocharger complete machine includes a volute 8, the side of the volute 8 is connected to the middle casing 9, and the middle casing 9 The other side is connected to the pressure shell 10. The vortex shaft is rotatably installed in the intermediate housing 9 , an impeller is installed at one end of the vortex shaft, and a pressure wheel is installed at the other end, the impeller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com