Closed-loop control loop performance evaluation method based on SFA and Hellinger distance

A closed-loop control and loop performance technology, which is applied in general control systems, control/regulation systems, test/monitoring control systems, etc., can solve the problems that the controlled variables are difficult to satisfy the Gaussian distribution, and the application effect cannot be obtained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the examples. The description of the following examples is provided only to aid the understanding of the present invention. It should be pointed out that for those skilled in the art, some modifications can be made to the present invention without departing from the principles of the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

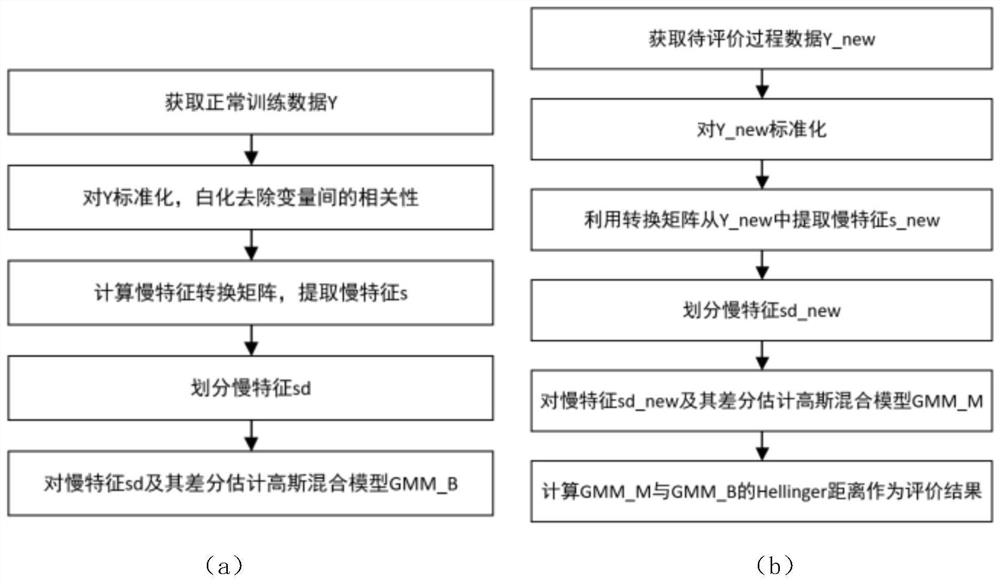

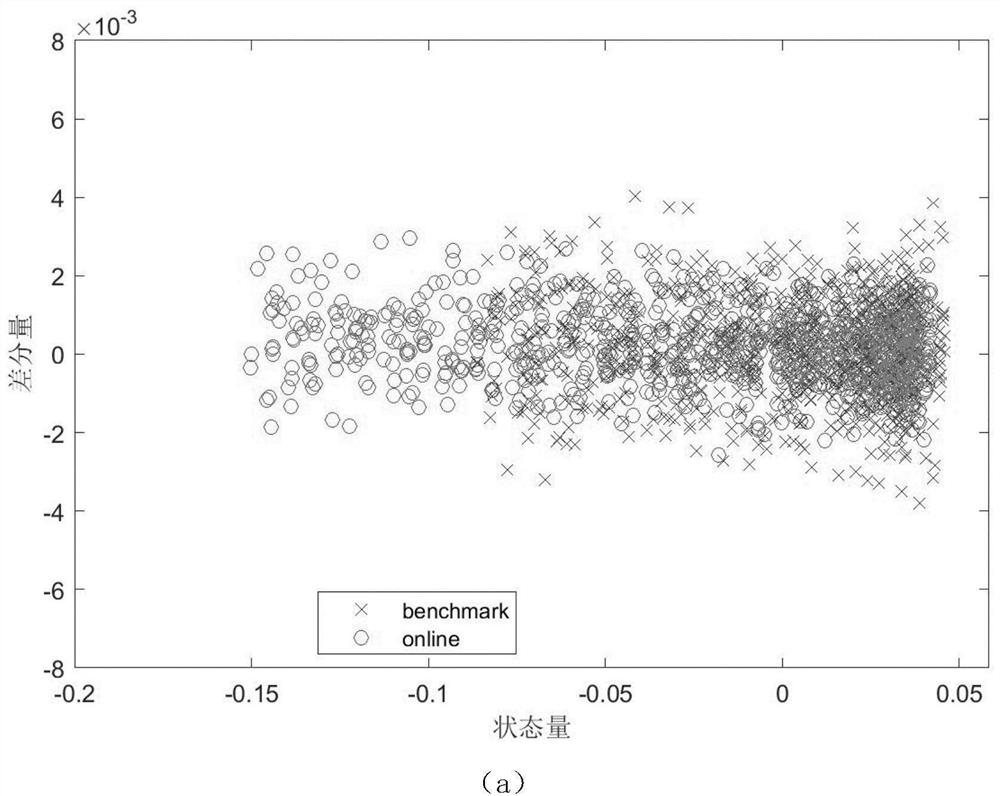

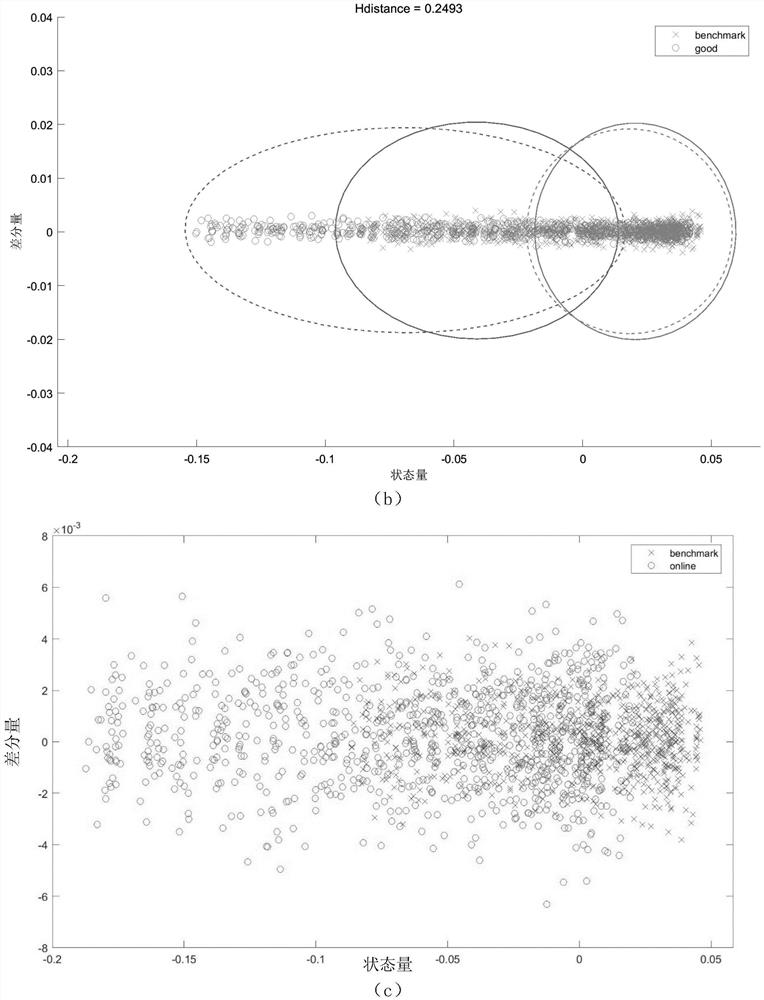

[0066] The invention aims at the problem that the control logic is highly coupled in the actual process, and the non-Gaussian distribution of the data makes it difficult to accurately evaluate the control performance. The slow feature analysis (SFA) algorithm is used to extract the dynamics of the reference data and the data to be evaluated, the operating variables and the controlled variables. Static information, and then estimate the Gaussian mixture model (GMM) of dynamic and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com