Method for controlling distance between light-emitting element and photosensitive element and optocoupler structure

A technology of photosensitive elements and light-emitting elements, which is applied to printed circuits connected to non-printed electrical elements, components of control amplifiers, and electrical elements, etc., can solve problems such as difficulties in on-site installation and debugging, and achieve the solution of difficult installation and debugging, The effect of improving installation efficiency and output resistance consistency, reducing installation requirements and difficulty of assembly and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

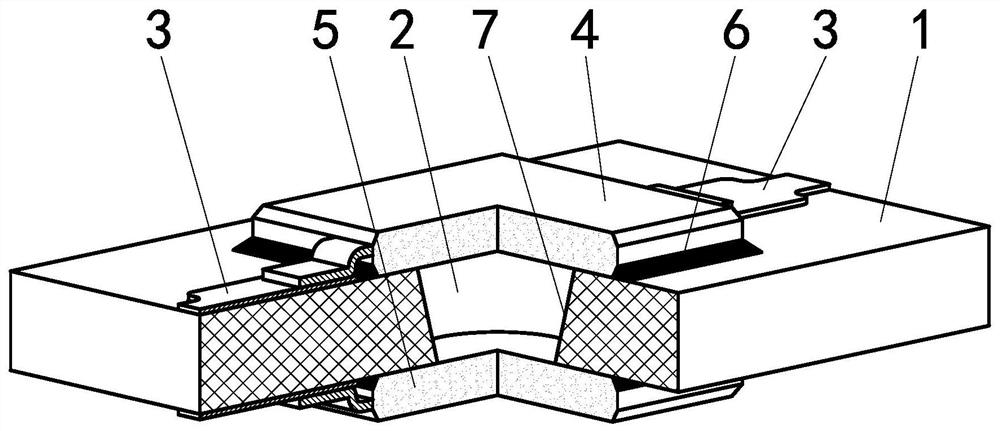

[0021] This example figure 1 As shown, the chip photoresistor 4 is included, and the chip photoresistor 4 is welded on the top surface of the printed board 1, and is welded on the bottom surface of the printed board 1 with a patch highlight lamp bead 5, and assembled together into an optocoupler structure. The printed board 1 is provided with a conical hole 2, and the top and bottom surfaces of the conical hole 2 are provided with a pad 3 and lead-out patch pins, wherein the pad 3 is used for welding the chip photoresistor 4 and the patch highlight Lamp bead 5, and the four SMD pins have two for the input of the optocoupler, and the other two are used for the output of the optocoupler.

[0022] This example is mainly to improve the optocoupler packaging method. The specific implementation is as follows: figure 1 As shown, the conical ring surface in the printed board can be drilled with a drill bit and metalized through the hole, and then the two components are directly welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com