Sorting device for non-docking sorting robot

A sorting device and robot technology, applied in sorting and other directions, can solve problems such as complex functions, high power consumption, and increased costs, and achieve the effects of smooth sliding of goods, reduced friction, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

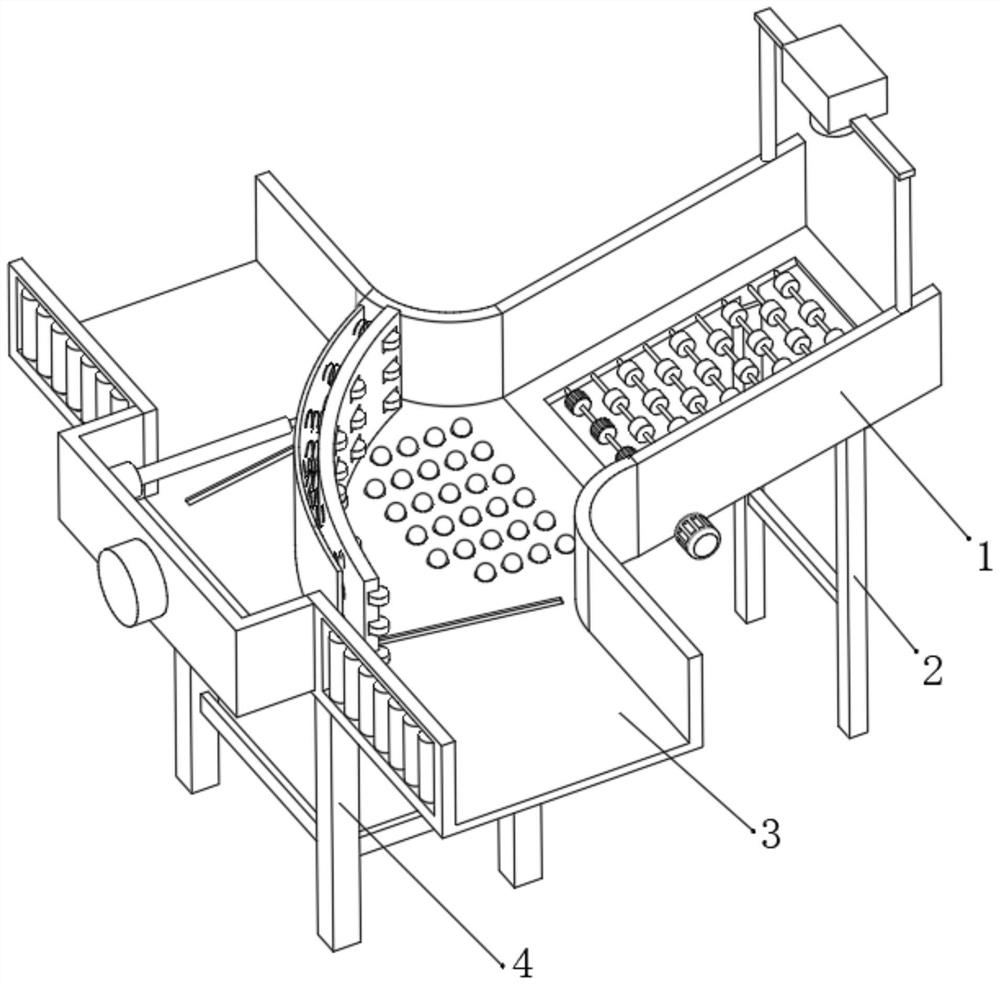

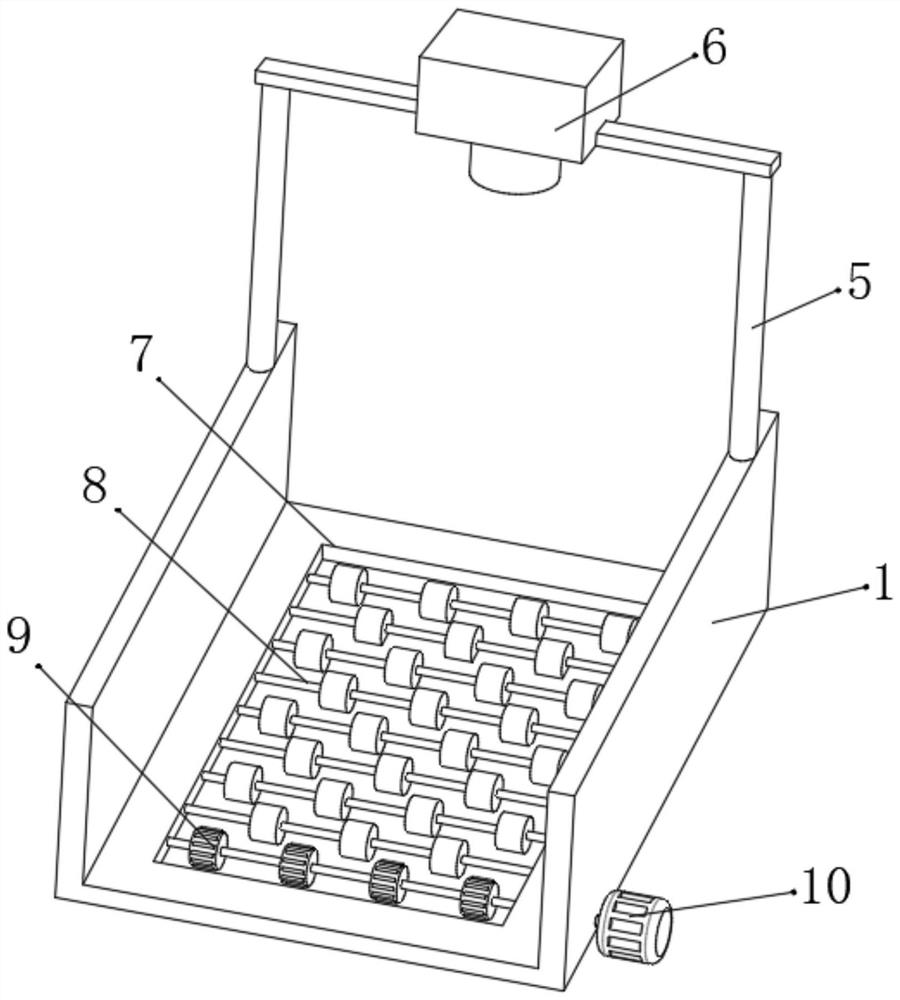

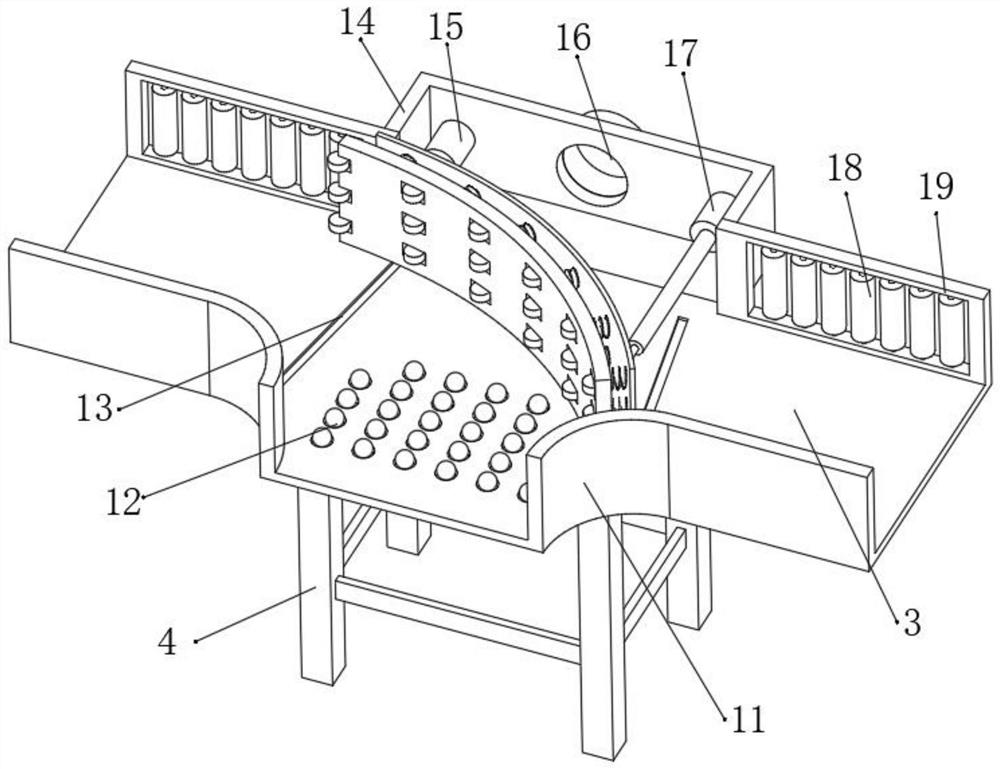

[0030] refer to Figure 1-4 , a sorting device for a non-stop sorting robot, including an acceleration slideway 1 and a sorting slideway 3, the acceleration slideway 1 and the sorting slideway 3 are connected by bolts, and the acceleration slideway 1 and the sorting slideway There is an inclination angle of 10°~40° between the roads 3, and the bottom of the acceleration slideway 1 is provided with a wheel groove 7, and the inner wall of the wheel groove 7 is connected with a plurality of wheel rods through bearing rotation, and the outer wall of the wheel rod is provided with A plurality of transfer pulleys 8, and the transfer pulleys 8 are installed in a staggered manner, and the outer wall of the wheel bar near the sorting slide 3 is provided with an acceleration pulley 9, and one end of the wheel bar is connected with a motor 10 by a bolt, and the motor 10 is connected to the acceleration pulley The channels 1 are connected by bolts, and the outer wall of one side of the so...

Embodiment 2

[0034] refer to Figure 5, a non-stop sorting robot sorting device. Compared with Embodiment 1, the inner wall of one side of the acceleration slideway 1 is located on both sides of the operation box 14 and has reserved openings, and the inner wall of the reserved opening A mounting rod is rotatably connected with a bearing, and the outer wall of the mounting rod is connected with a transmission slide rod 24 through bolts.

[0035] Working principle: When in use, this device can be used as the preliminary sorting device of the sorting robot. The goods enter from the acceleration slide 1 through the conveyor belt and other transportation devices, and are scanned by the scanner 6, which transmits the electrical signal to the Controller 16, controller 16 controls the elongation and contraction of the first electric telescopic rod 15 and the second electric telescopic rod 17, and adjusts the arc plate 20 to a suitable position. The angle of inclination, when the goods pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com