Preparation method of eucalyptus bark powder modified phenolic resin wood adhesive

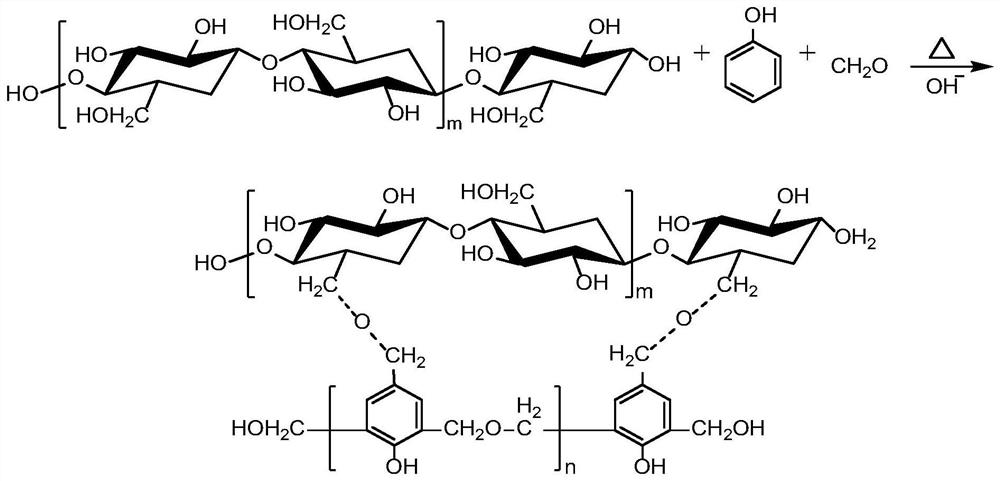

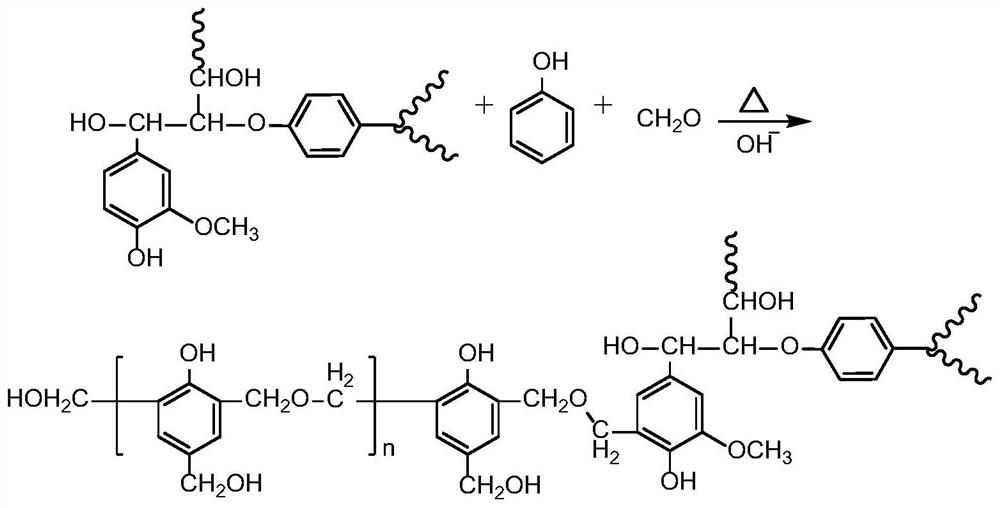

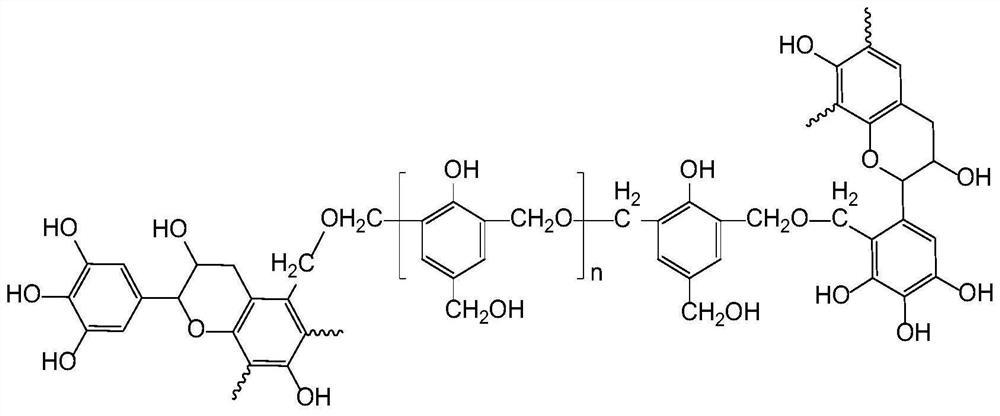

A technology of wood adhesives and eucalyptus bark powder, which is applied in the direction of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., and can solve the problems of unseen modified phenolic resin wood adhesives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation method of eucalyptus bark powder modified phenolic resin wood adhesive, comprising the following steps:

[0036] (1) Add 600kg phenol, 240kg eucalyptus bark powder and 1050kg first batch of formaldehyde into the ball mill tank, ball mill for 100min, then add 545kg water to obtain the mixed material;

[0037] (2) Transfer the mixed material to the reaction kettle, add 350kg of the first batch of alkali while stirring, heat to 93°C, and react for 45min;

[0038] (3) Add 310kg of the second batch of formaldehyde, stir evenly, then add 70kg of the second batch of alkali, react at 90°C for 55min, cool to 40°C, and discharge to obtain eucalyptus bark powder modified phenolic resin wood adhesive.

Embodiment 2

[0040] A preparation method of eucalyptus bark powder modified phenolic resin wood adhesive, comprising the following steps:

[0041] (1) 600kg of phenol, 280kg of eucalyptus bark powder and 1150kg of the first batch of formaldehyde were added to the ball mill tank, ball milled for 110min, and then 585kg of water was added to obtain the mixed material;

[0042] (2) Transfer the mixed material to the reaction kettle, add 380kg of the first batch of alkali while stirring, heat to 94°C, and react for 42min;

[0043] (3) Add 330kg of the second batch of formaldehyde, stir evenly, then add 75kg of the second batch of alkali, react at 91°C for 53min, cool to 40°C, and discharge to obtain eucalyptus bark powder modified phenolic resin wood adhesive.

Embodiment 3

[0045] A preparation method of eucalyptus bark powder modified phenolic resin wood adhesive, comprising the following steps:

[0046] (1) 600kg phenol, 200kg eucalyptus bark powder and 950kg first batch of formaldehyde were added to the ball mill tank, ball milled for 90min, then 500kg water was added to obtain the mixed material;

[0047] (2) Transfer the mixed material to the reaction kettle, add 330kg of the first batch of alkali while stirring, heat to 92°C, and react for 47min;

[0048] (3) Add 290kg of the second batch of formaldehyde, stir evenly, then add 65kg of the second batch of alkali, react at 89°C for 57min, cool down to 40°C, and discharge to obtain eucalyptus bark powder modified phenolic resin wood adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bonding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com