Fluid drive device and power generator with same

A fluid-driven and fluid-driven technology, applied in the field of generators, can solve the problems of insufficient and effective utilization of hydraulic residual energy, insufficient and effective utilization of residual heat, etc., and achieve easy access, tight spacing, and increased contact area. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present application will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

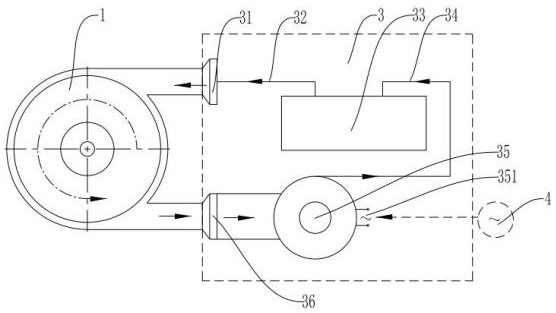

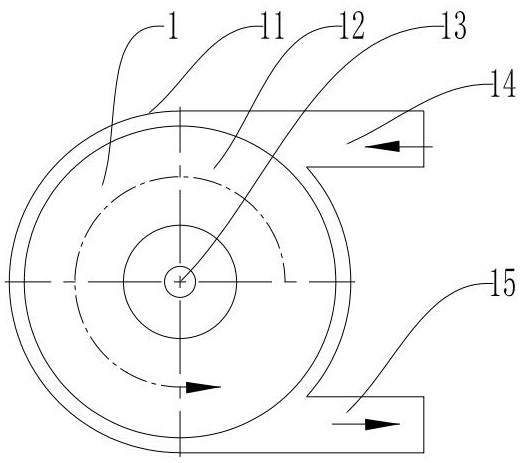

[0032] Such as figure 1 As shown, a fluid driving device includes a fluid driver 1 and a fluid circulation system 3. The connection between the fluid circulation system 3 and the fluid driver 1 is an airtight communication connection, and the fluid flows in the fluid circulation system 3. After being pressed, it is sprayed into the fluid driver 1, and through contact with the surface of the driving part of the fluid driver 1, the generated frictional force pushes the driving part to rotate, thereby driving the fluid driver 1 to run.

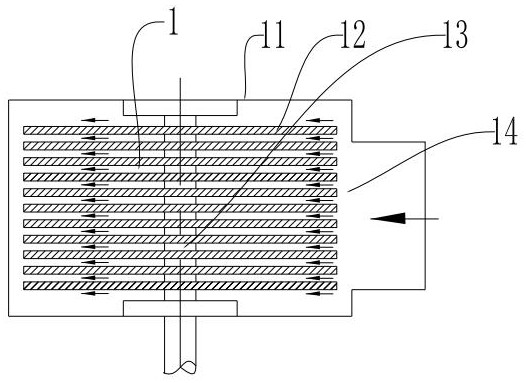

[0033] In order to simplify the structure of the fluid driver, improve operational reliability, and reduce the manufacturing and maintenance costs of the fluid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com