Magnesium alloy anode material for seawater battery and preparation method of magnesium alloy anode material

A technology for anode materials and seawater batteries, applied in battery electrodes, immersion batteries, circuits, etc., can solve problems such as fast corrosion speed and difficult processing of anode materials, and achieve easy dissolution, reduced galvanic corrosion tendency, and grain refinement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Take AZ31 (Mg-3.48wt.%Al-0.99wt.%Zn-0.46wt.%Mn), pure magnesium (99.95wt%), Mg-20wt.%Ca raw materials, and weigh the raw materials. in CO 2 (99vol%) and SF 6 (1vol%) under the protective atmosphere of mixed gas, the melting temperature is 700 ~ 720 ° C, the raw materials are completely melted and stirred, and then poured into a steel mold after standing for 10 minutes to obtain a block magnesium alloy anode material ingot, which is recorded as AZ31 -1.0Ca;

[0029] 2) Use a wire electric discharge machine to cut a cuboid ECAP sample with a size of 45×20×20mm and heat the ECAP mold to 300-310°C, then put the magnesium alloy sample evenly coated with graphite milk into the mold and keep it warm for 10 minutes , followed by 8 passes of ECAP processing; the ECAP mold cavity used is in the shape of a "ten", and reciprocating processing can be achieved by rotating 90° during processing to obtain a uniform and refined structure. The processed anode material is denoted as...

Embodiment 2

[0031] 1) Take AZ31 (Mg-3.48wt.%Al-0.99wt.%Zn-0.46wt.%Mn), pure magnesium (99.95wt%), Mg-20wt.%Ca as raw materials, and weigh the raw materials. in CO 2 (99vol%) and SF 6 (1vol%) under the protection atmosphere of the mixed gas, melting temperature 700~720 ℃, after raw material is melted completely, stir, after standing for 10 minutes, pour into the steel mold and obtain block magnesium alloy anode material ingot;

[0032] 2) Use a wire electric discharge machine to cut a cuboid ECAP sample with a size of 45×20×20mm and heat the ECAP mold to 300-310°C, then put the magnesium alloy sample evenly coated with graphite milk into the mold and keep it warm for 10 minutes , followed by 12 passes of ECAP processing, and the resulting anode material is denoted as AZ31-1.0Ca 12p.

[0033] performance analysis

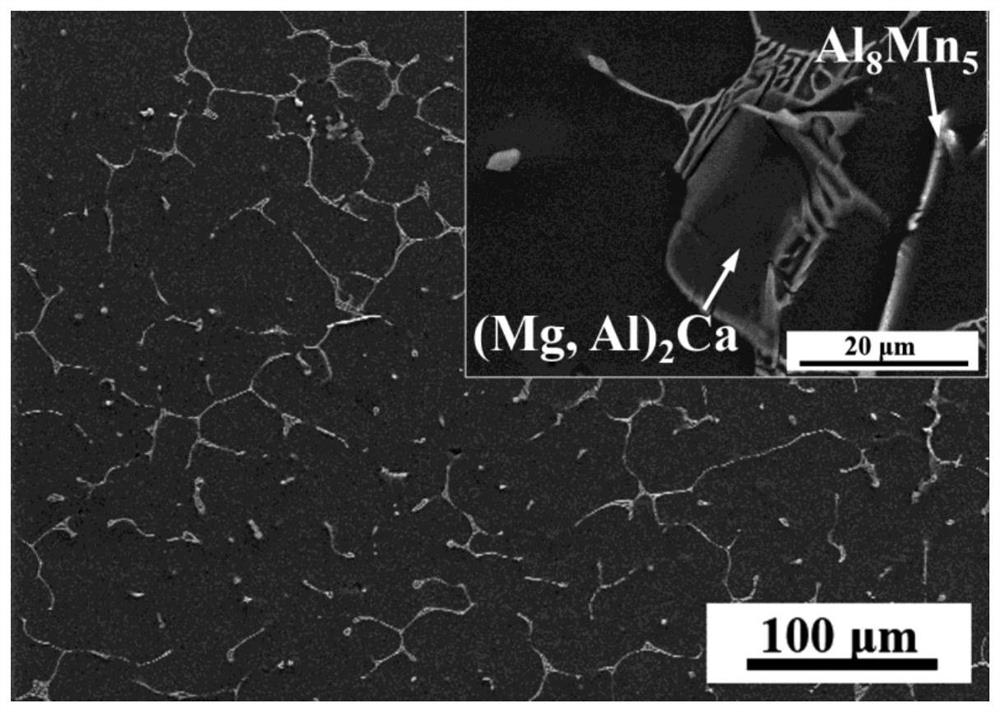

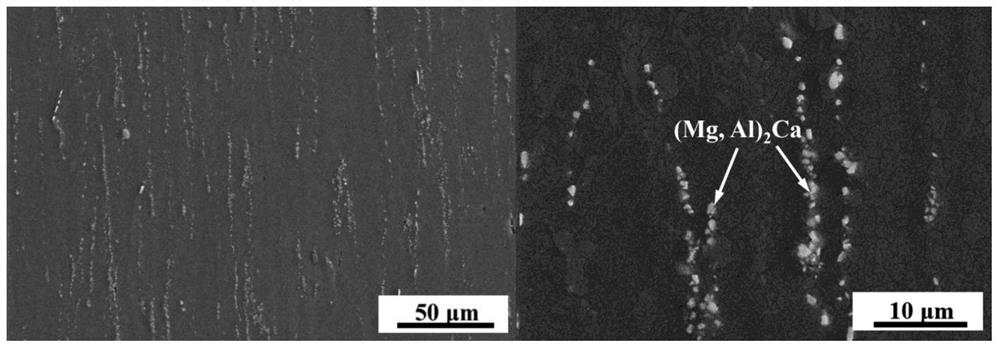

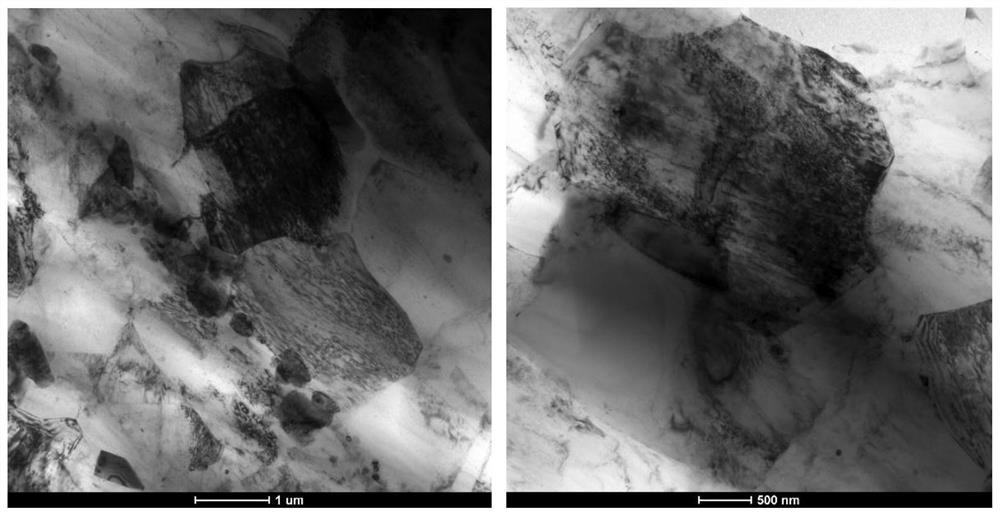

[0034] like figure 1 As shown, after alloying with 1.0wt.% Ca, a network (Mg, Al) precipitated along the grain boundary is formed in the AZ31-1.0Ca alloy 2 Ca phase. After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| discharge efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com