Steel pipe close-range inner and outer wall flushing device after acid pickling

A flushing device and short-distance technology, which is applied in the field of flushing the inner wall of steel pipes, can solve the problems of great physical injury to the operator, reduced pressure, flow rate, and large power consumption, etc., to achieve the effect of reducing cleaning time, saving flow and pressure, and saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

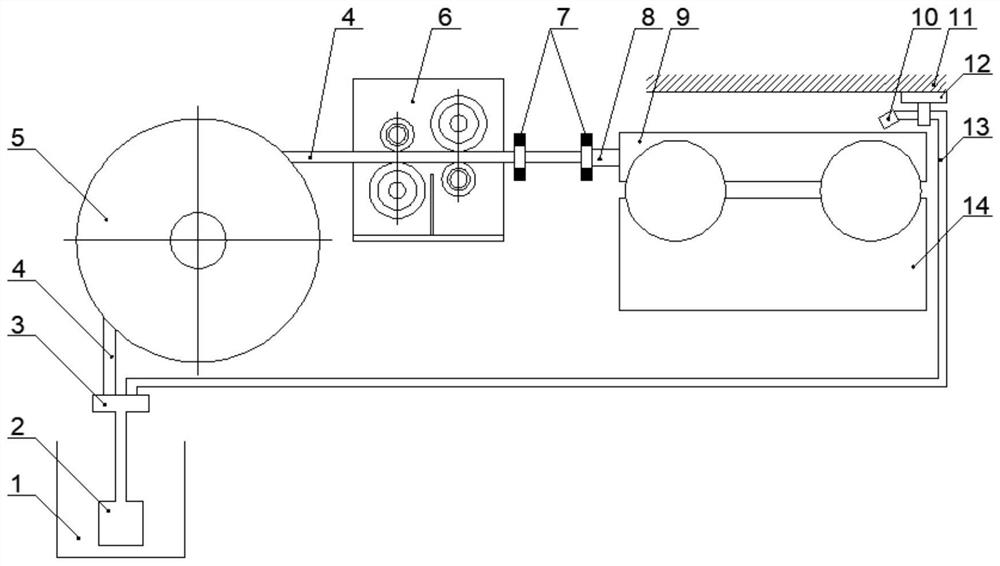

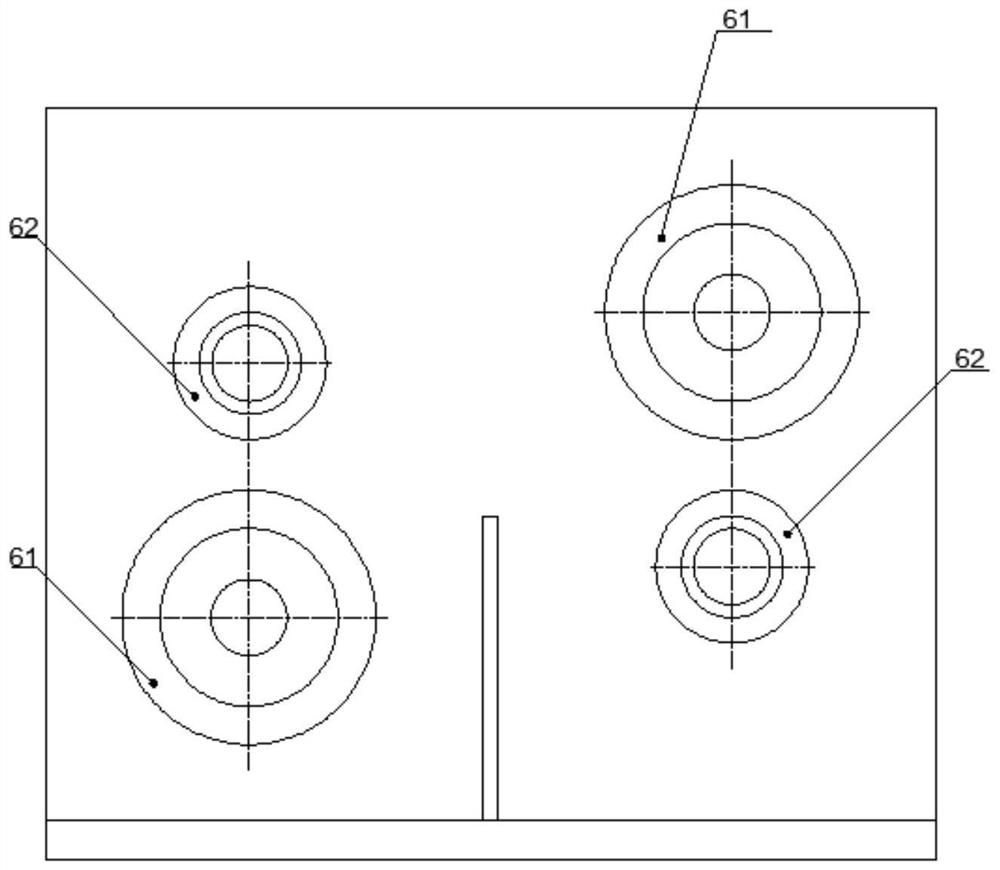

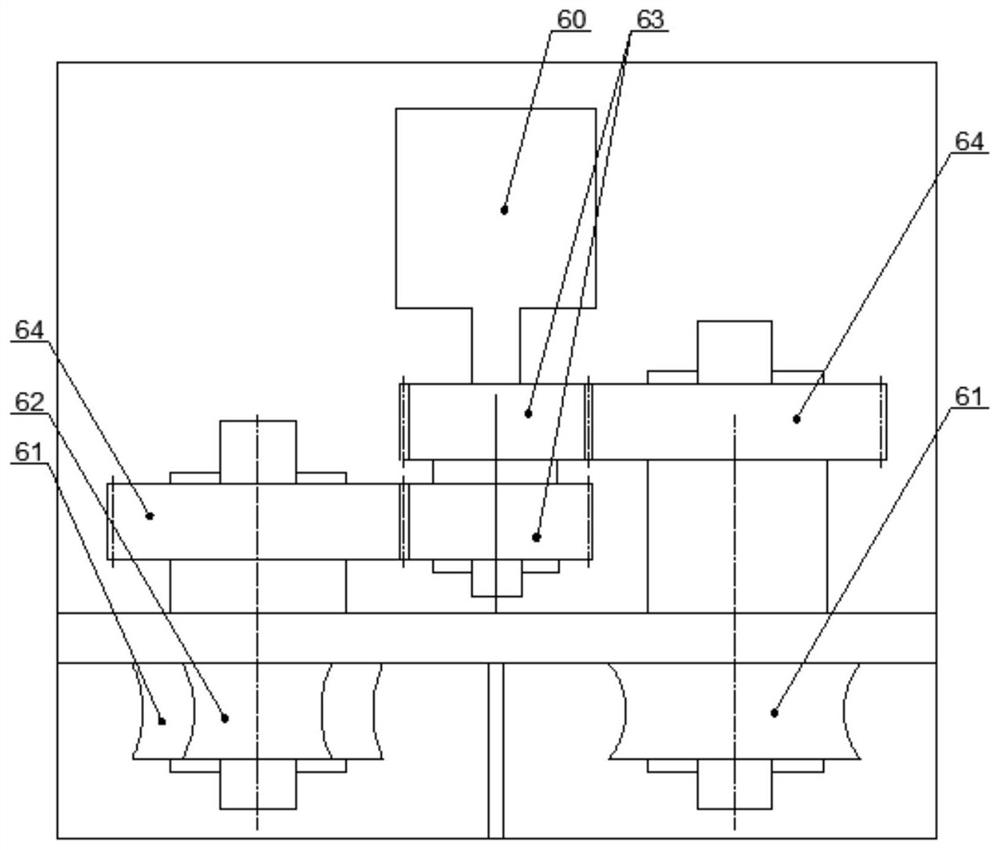

[0041] Such as Figure 1-7 As shown, a close-distance flushing device for the inner and outer walls of steel pipes after pickling includes a liquid storage and supply mechanism, a flow divider 3, a first high-pressure hose 4, a second high-pressure hose 13, a steel pipe placement platform 14, a pipeline delivery mechanism, The inner wall flushing mechanism and the outer wall flushing mechanism. The liquid storage and supply mechanism includes a water storage tank 1, a high-pressure pump 2 and a high-pressure main pipe. The high-pressure pump 2 is arranged in the water storage tank 1 containing flushing liquid. One end of the main pipe and the other end of the high pressure main pipe are connected to the water inlet of the flow divider 3 . The flushing liquid stored in the water storage tank 1 is a cleaning liquid specially used for flushing steel pipes, but different flush...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap