Device for preventing splashing of machine tool waste and using method thereof

A waste material and waste hopper technology, which is applied in the direction of auxiliary devices, tool holder accessories, metal processing machinery parts, etc., can solve the problems of reducing the service life of the tool, the danger of the operator, and affecting the processing efficiency, so as to reduce the risk and improve the structural accuracy. High, the effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

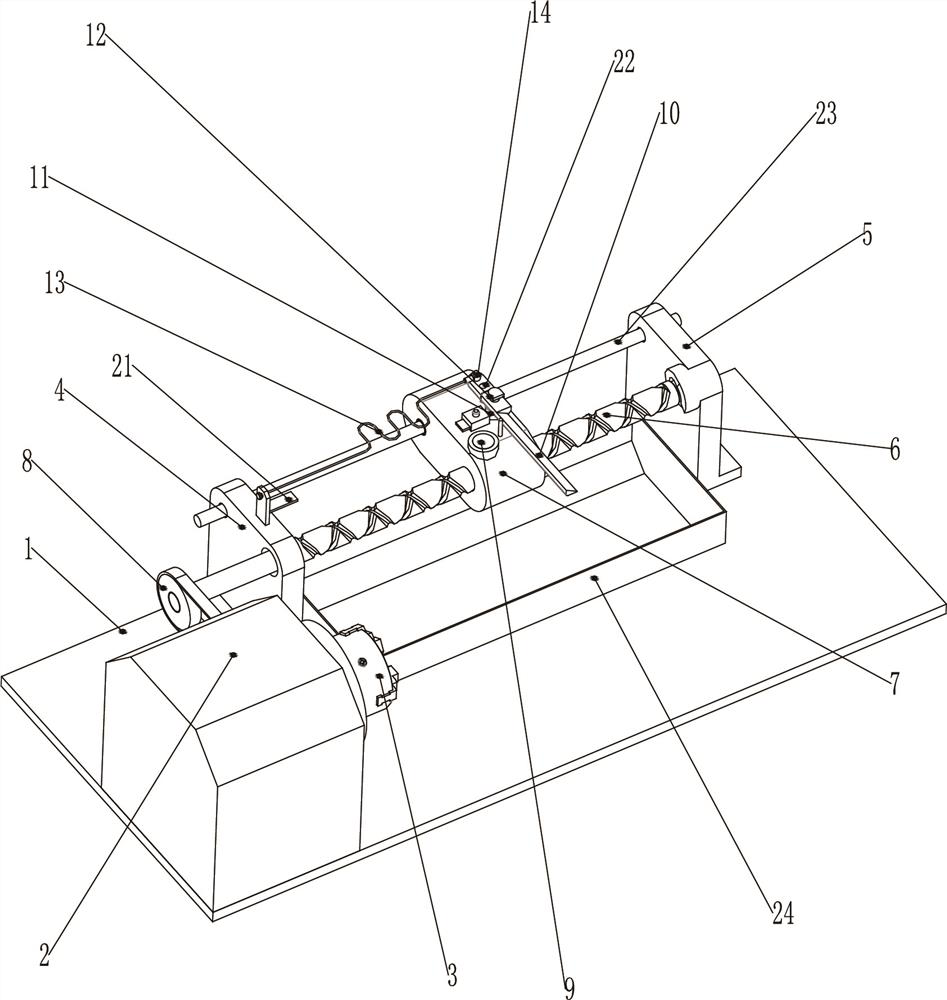

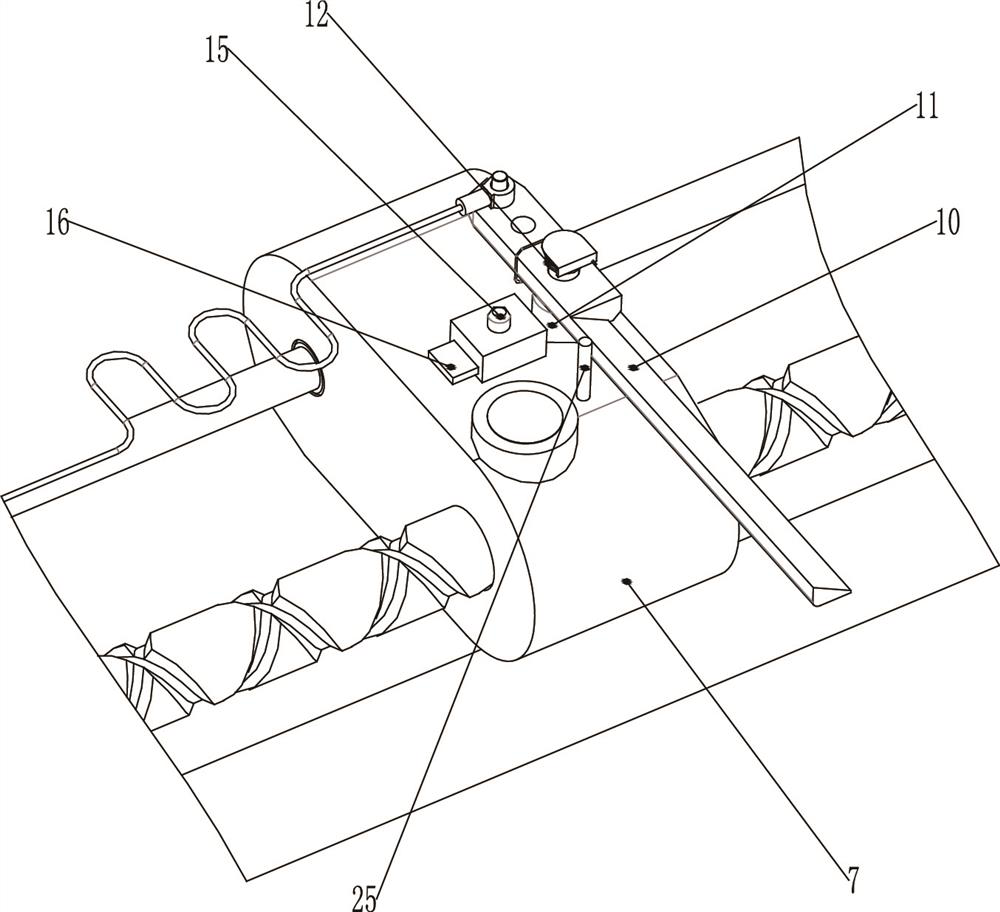

[0019] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 , figure 2 , image 3 and Figure 4 , a device for preventing machine tool waste from splashing, comprising a lathe bed 1, a headstock 2 and a three-jaw chuck 3, the headstock 2 is fixed on one side of the lathe bed 1, and the three-jaw chuck 3 is arranged on the headstock 2 and rotates synchronously with the main shaft, and the workpiece with turning is clamped on the three-jaw chuck 3 and rotates together with the three-jaw chuck 3.

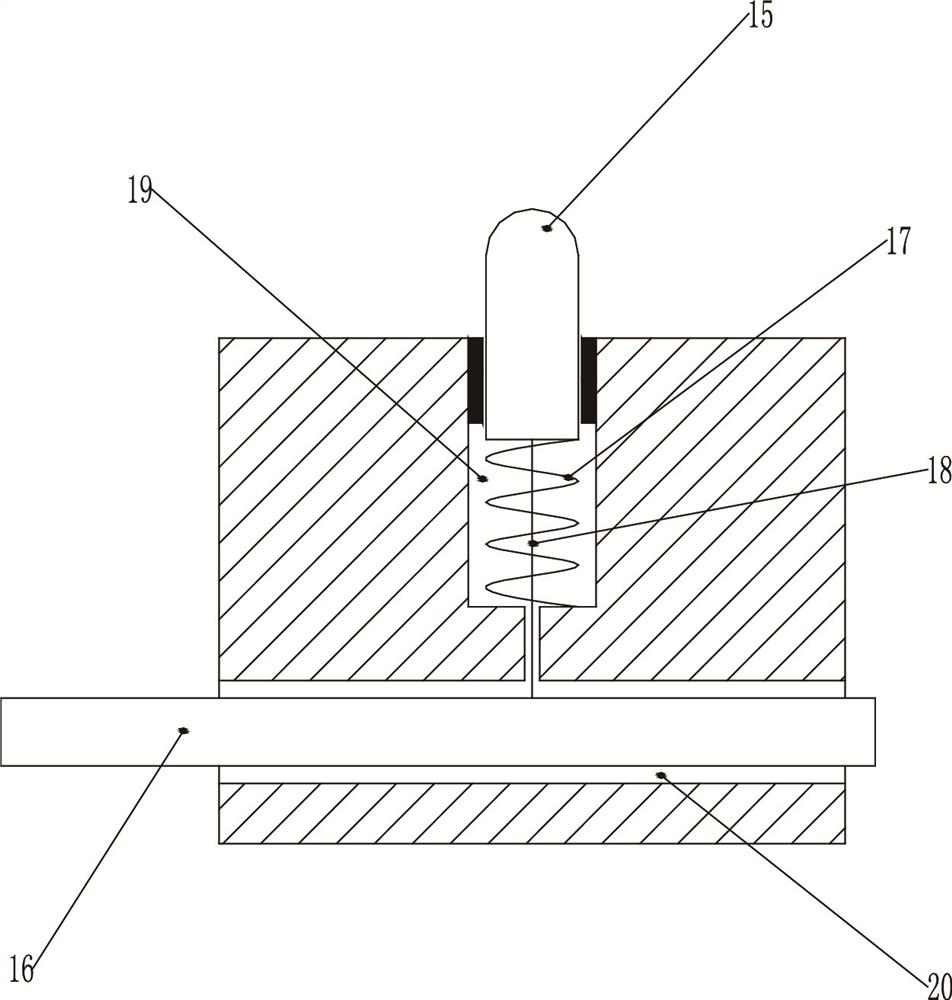

[0020] Preferably, one side of the three-jaw chuck 3 is provided with a reciprocating mechanism, and the reciprocating mechanism includes a first support 4, a second support 5, a reciprocating screw rod 6, and a guide slider 7, and the first support 4 and the second support 5 are respectively fixed on both sides of the lathe bed 1, and the two ends of the reciprocating screw mandrel 6 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com