A CNC machining center with automatic loading and unloading and its automatic loading and unloading method

An automatic loading and unloading and processing center technology, applied in stone processing equipment, stone processing tools, metal processing equipment, etc., can solve the problems of long auxiliary time for refueling, labor intensity and labor hazards, and large machine tools, etc. Safety and refueling efficiency, improved controllability, and strong scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

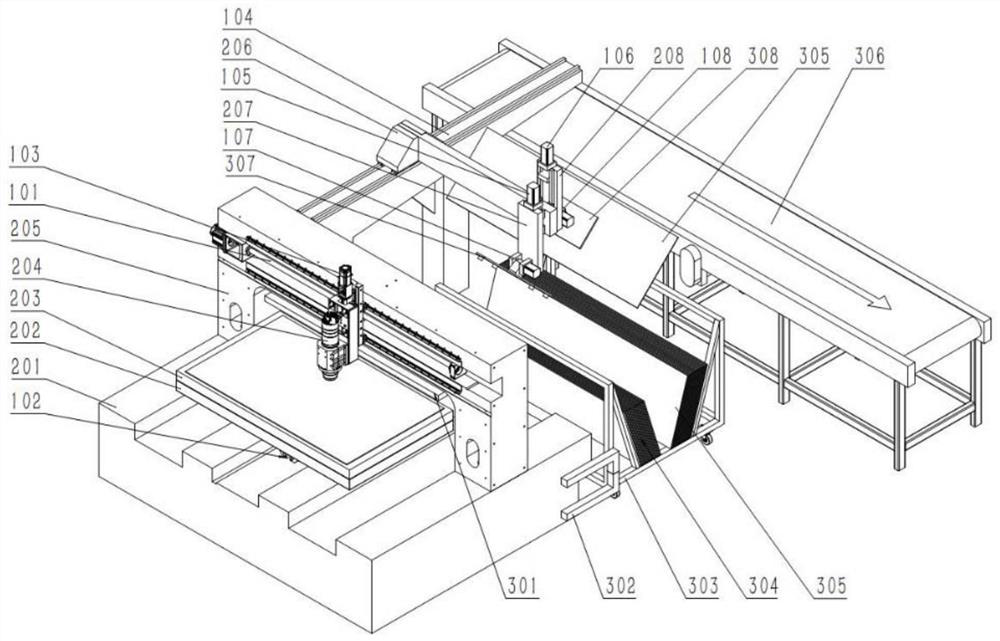

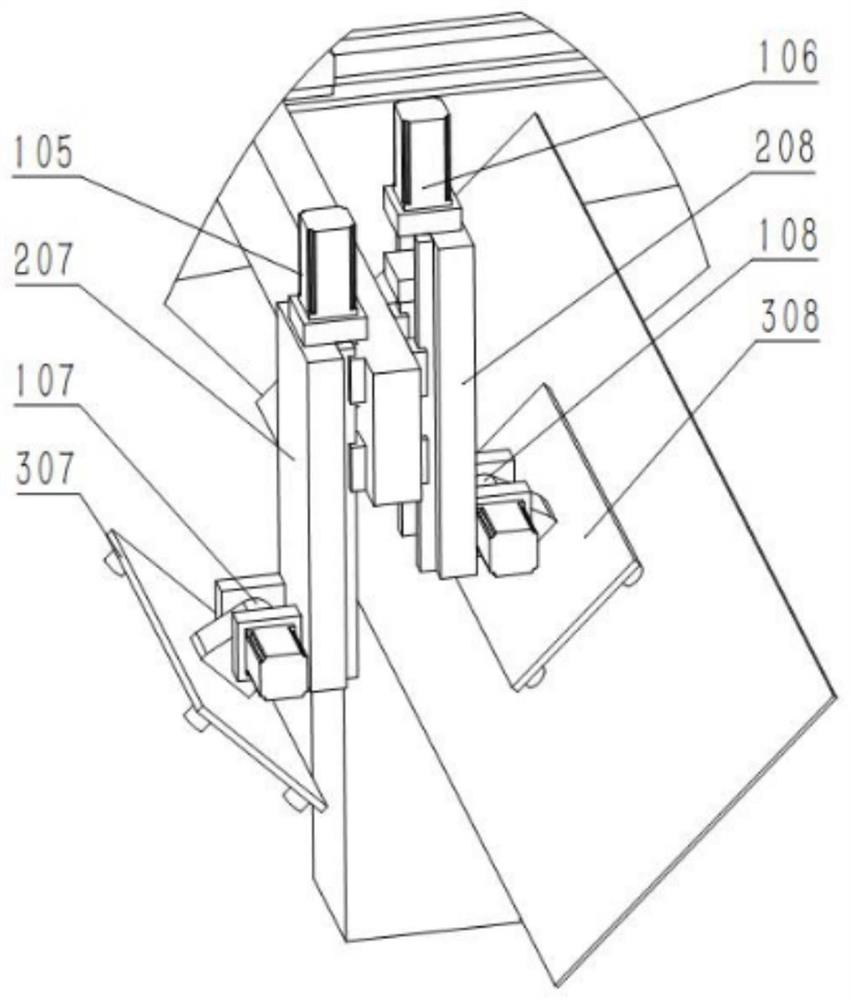

[0044] Such as figure 1 As shown in the figure, the CNC machining center with automatic loading and unloading provided by the present invention includes a CNC machine tool, a multi-terminal automatic reloading device and a rack device with a blank pick-and-place end and a finished product pick-and-place end;

[0045] The material rack device 303 is set independently of the CNC machine tool, and is located behind the CNC machine tool, in accordance with the direction shown in the figure.

[0046] The multi-terminal automatic refueling device is erected on the machine bed of the numerically controlled machine tool, and moves back and forth relative to the machine bed. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com