A workpiece transport device

A technology for workpiece transportation and equipment, which is applied in metal processing equipment, grinding workpiece support, grinding/polishing equipment, etc., can solve the problems of workpiece processing efficiency, single structure and function of cart, and processing, so as to facilitate maintenance and reduce Processing time and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

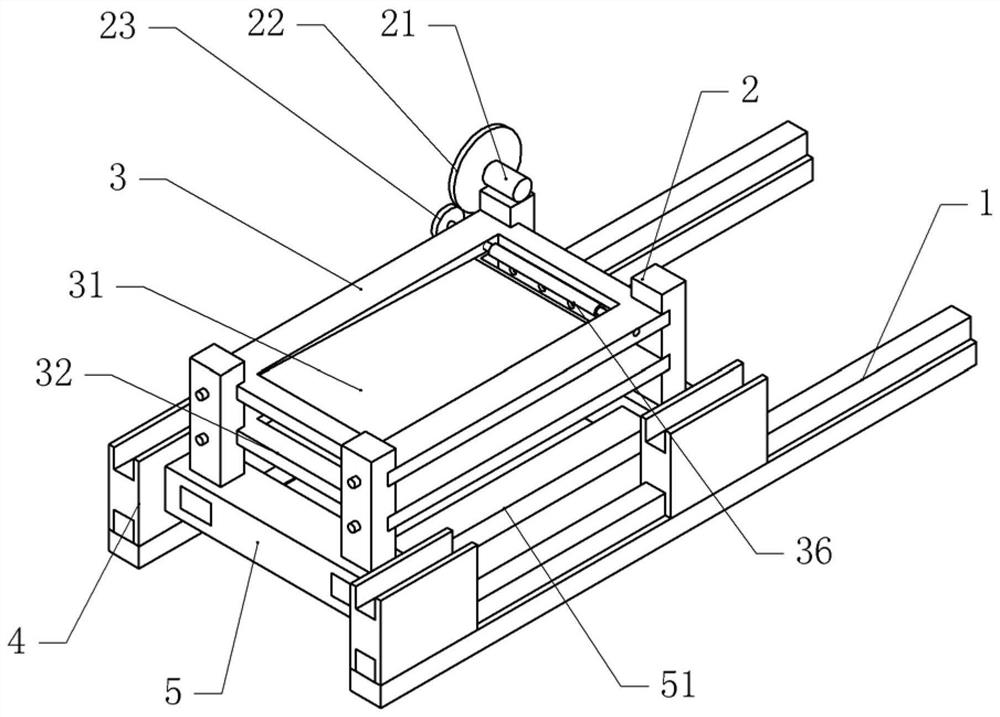

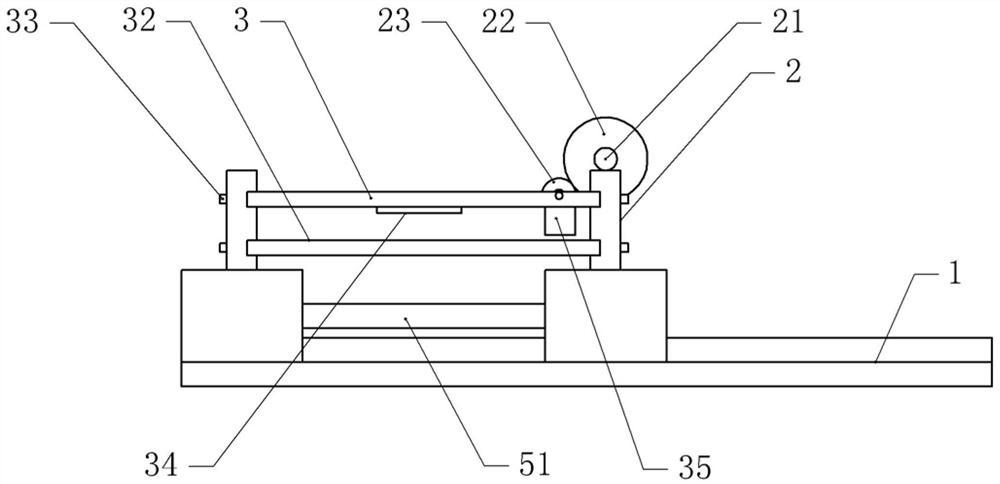

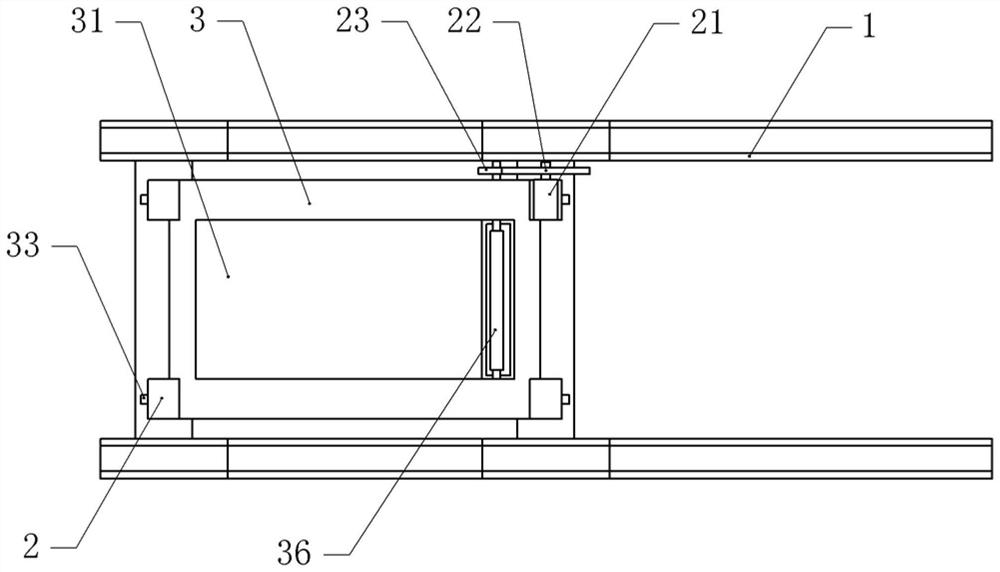

[0039] Basic as attached figure 1 And attached figure 2 As shown, a workpiece transportation device includes two guide rails 1, and the guide rails 1 are fastened to the ground by bolts. The top of the guide rail 1 is provided with a vehicle frame 5, on which the bolts are fixed with a reinforcement shaft 51, and both sides of the vehicle frame 5 are fixed with guide blocks 4 by bolts, the number of guide blocks 4 on each side of the vehicle frame 5 in this embodiment There are two guide blocks 4 on both sides that are horizontally slidably connected to the guide rail 1.

[0040] as attached image 3 , attached Figure 4 , attached Figure 5 And attached Image 6 As shown, two support shafts 2 are fixed with bolts on both sides of the support shaft 2, and the side of the support shaft 2 facing the middle of the vehicle frame 5 is provided with a number of draw-in slots, and the inner threads of the draw-in slots are connected with fasteners 33. The fastener 33 is a bolt...

Embodiment 2

[0048] The difference between embodiment two and embodiment one is that, as attached Figure 7 As shown, the left side of the vehicle frame 5 has a cavity, and a pressure plate 52 is vertically slidably connected in the cavity, and the upper end of the pressure plate 52 is hinged with a connecting rod. The connecting rod and the main gear 22 constitute a slider crank mechanism.

[0049] The pressure plate 52 separates the cavity into an upper chamber and a lower chamber. The lower chamber communicates with a first air intake check valve 58 fixed on the vehicle frame 5 by screws. The first air intake check valve 58 communicates with an air pipe 57. The air pipe 57 and The pipe fitting 35 communicates, and the lower chamber communicates with the first air outlet one-way valve 53, the first air outlet one-way valve 53 communicates with the outside air, and the inner side wall of the lower chamber is fixed with a filter screen for filtering the first air outlet one-way valve 53 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com