Rapid packaging machine for canned fruits

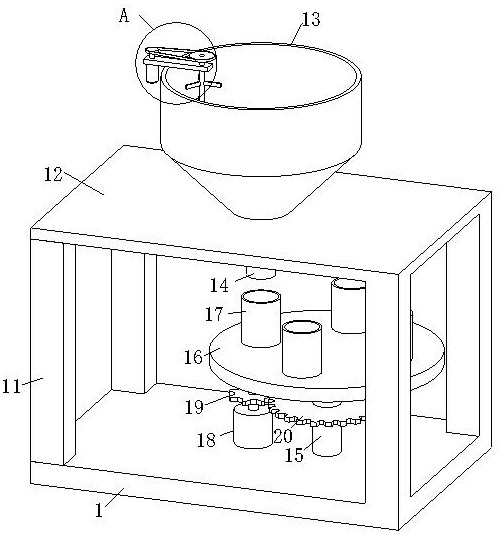

A technology of canned fruit and fast packaging, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of polluting the packaging machine, liquid splash waste, and impacting the pulp of the tank, so as to increase efficiency, reduce splash, and increase perfusion. speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

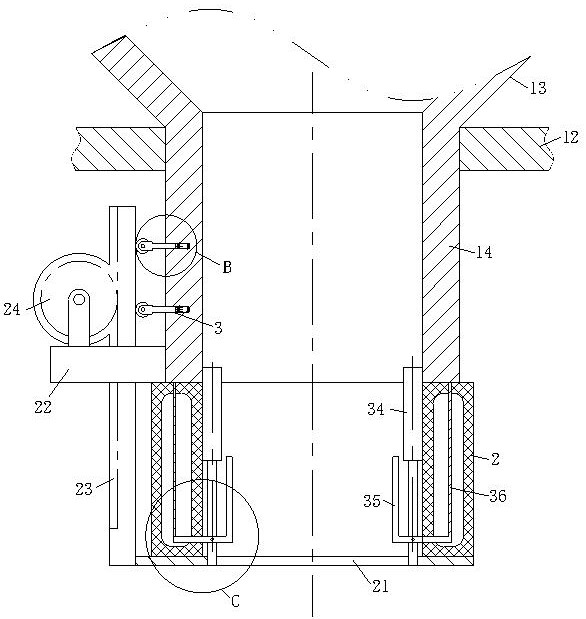

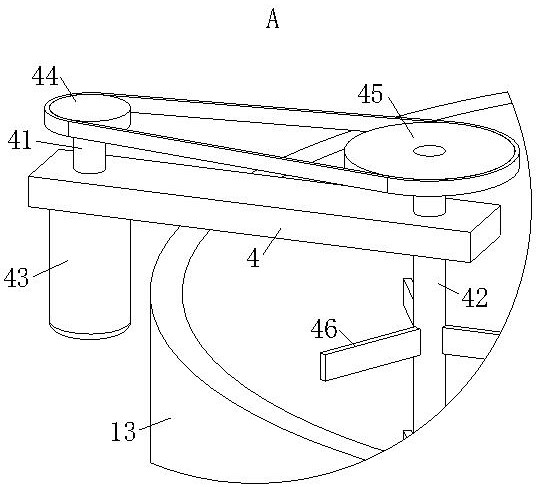

[0024] As an embodiment of the present invention, the support unit 3 includes a sliding hole 31 provided on the outer periphery of the feeding pipe 14, a sliding column 32 is slidably connected to the sliding hole 31, and a spring is arranged between the sliding column 32 and the bottom of the sliding hole 31. One end of the spool 32 close to the rack 23 is rotatably connected with a support wheel 33; the spool 32 is supported by a spring, so that the sled 32 drives the support wheel 33 to be close to the rack 23, so that the rack 23 and the third gear 24 are in good condition The meshing further increases the sliding efficiency of the rack 23, reduces the wear of the rack 23, and reduces the maintenance frequency of the packaging machine.

[0025] As an embodiment of the present invention, the third gear 24 is elliptical; the rack 23 is fixedly connected with the fixed ring 21 through an elastic rod, and the rack 23 is in clearance fit with the first bracket 22; The number ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com